3 inlet and outlet piping, 4 afterfilter, 5 drain valve – Van Air Systems PLD 8-2.8 / 36-2.8 User Manual

Page 3: 2 piping and ancillary equipment

PAGE 3

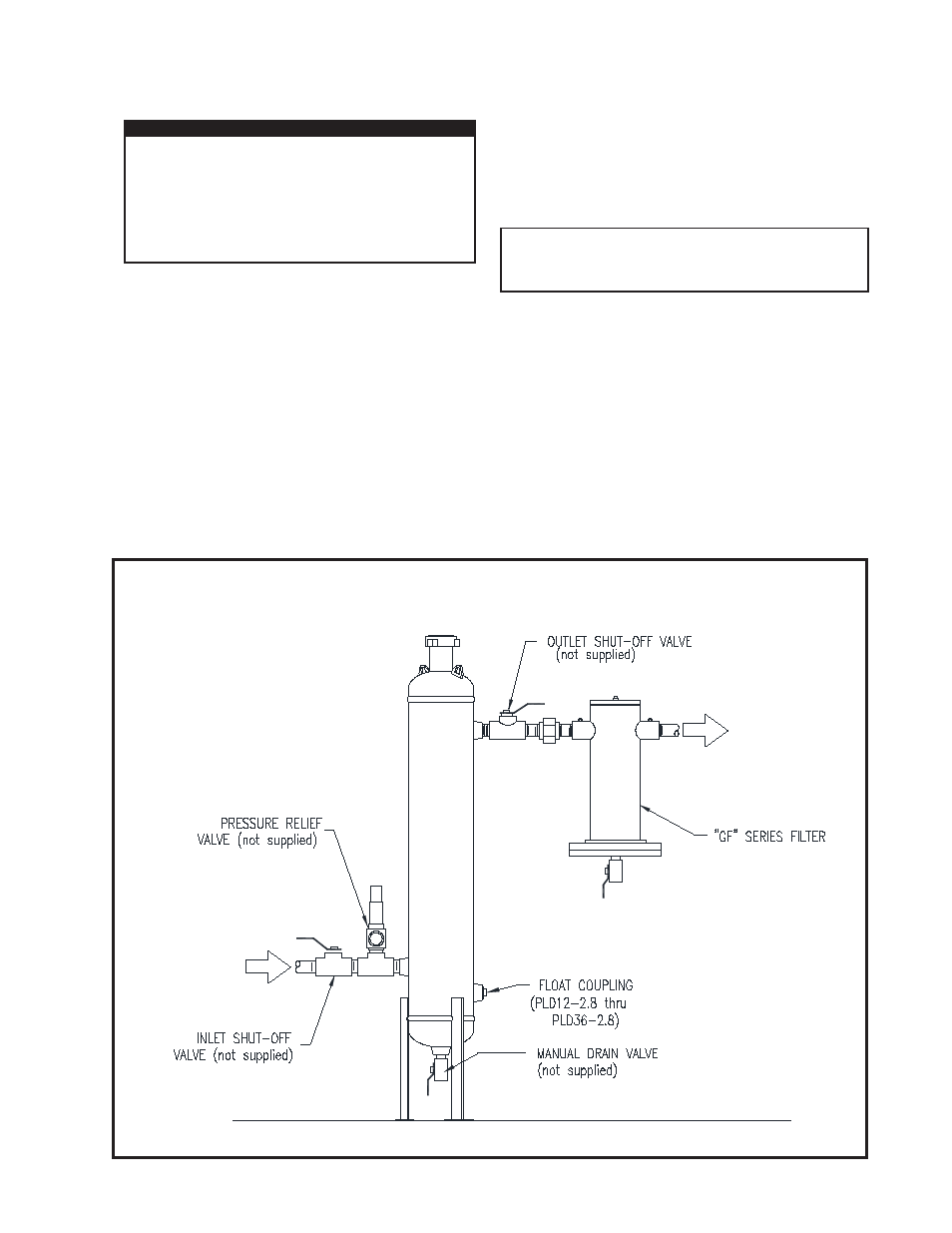

FIGURE 2-A RECOMMENDED INSTALLATION

2.3 INLET AND OUTLET PIPING

NOTE

Inlet and outlet shut-off valves will make start-up

and addition of desiccant easier.

Two shut-off valves should be installed (not furnished with

dehydrator)-one at dryer inlet and another at dryer outlet. See

Figure 2-A Recommended Installation.

Connect the inlet and outlet piping as shown in Figure 2-A.

2.4 AFTERFILTER

Van Gas "GF" Series Filters can be installed downstream of the

dehydrator to remove particulate contamination from the natural

gas. Contact Van Gas for details.

2.5 DRAIN VALVE

Install a drain valve (not furnished with dehydrator) in the drain

coupling at the bottom of the tower (except on PLD8-2.8). A float/

auto drain valve system is available. Contact Van Gas for details.

IMPORTANT

COMPLY WITH ALL FEDERAL, STATE, AND

LOCAL REGULATIONS CONCERNING

INSTALLATION OF NATURAL GAS SYSTEMS.

COMPLIANCE TO AND KNOWLEDGE OF ALL

REGULATIONS IS THE RESPONSIBILITY OF

THE INSTALLER.

Install a pressure relief valve in the up-stream piping (relief

valve not furnished). A relief valve must be installed to

conform with the ASME Boiler and Presssure Vessel Codes,

Section VIII, Division 1 UG-125, Paragraph (1) and OSHA

standards. Also comply with all applicable Federal, State,

and Local codes.

2.2 PIPING AND ANCILLARY EQUIPMENT

Make sure that the temperature of gas is not over the maximum

for the desiccant being used. If gas temperature is too high, cool it

prior to the dehydrator.

Mount the dehydrator on a level surface capable of supporting the

weight of the vessel, such as a cement pad or a skid.