Van Air Systems HLS-50-HLS-150 User Manual

Page 7

PRINTED IN THE U.S.A.

PAGE 7

USING THE DRYER

SECTION 7

7.1 CONTROLLER

The Controller is a compact NEMA 4 control box. It has the following features:

• Dryer Status LEDs

- POWER ON LED - L/R TOWER DRYING LEDS

- RUN LED - L/R TOWER REGENERATING

LEDS

- HOLD LED - DRYER PURGING LED

- SWITCHING FAILURE LED

The Dryer Status LEDs are located on the front panel of the control box.

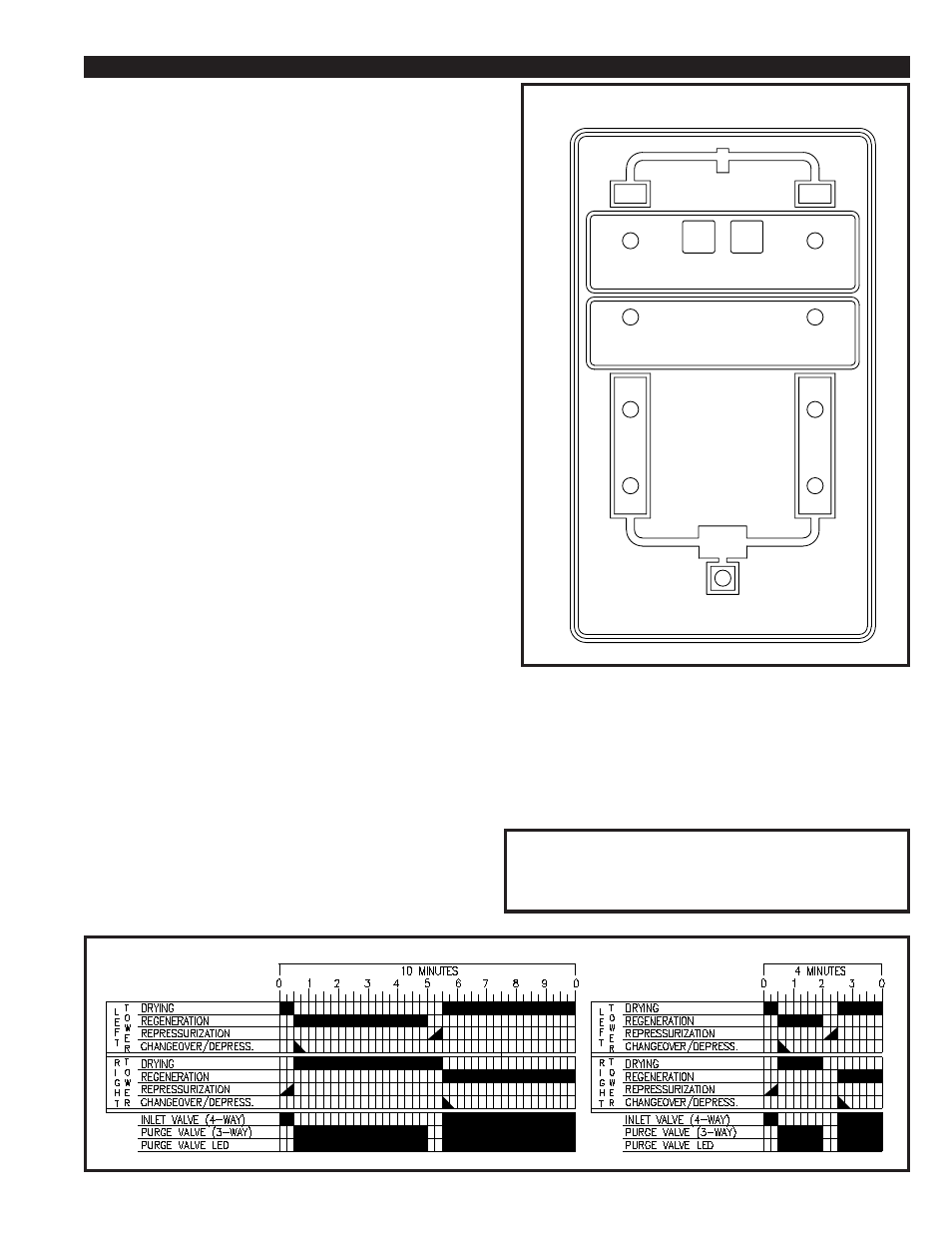

Figure 7A shows the location of each.

When the Left tower is pressurized and on line drying the process air, the

corresponding LEFT TOWER DRYING LED is illuminated. When the right

tower is pressurized and on line drying the process air, the corresponding

RIGHT TOWER DRYING LED is illuminated.

The DRYER PURGING LED is illuminated when the purge exhaust valve

is energized open. During repressurization this LED will not be illuminated.

Repressurization occurs for approximately 20 seconds just before tower

changeover.

The operation sequence of the dryer is shown in FIGURE 7B TIMING

CHART.

FIGURE 7A

LEFT

RIGHT

POWER ON

STOP

RUN

RUN

TOWER DRYING

HOLD

SWITCHING FAILURE

TOWER REGENERATING

DRYER PURGING

SWITCHING FAILURE:

When there is a switching failure, the LED will be lit. This will energize

the contacts shown in FIGURE 4B. The contacts can be wired for

remote annunciation. To reset the Switching Failure Alarm press the

run button on the control box front panel.

HOLD FEATURE:

For low load or static pressure conditions, the hold contacts shown on

Figure 4B can be wired to an auxillary set of normally closed contacts

on the compressor starter. This will stop the cycling of the dryer and

repressurize both towers of the dryer, until there is demand on the

compressor. The Hold LED will light, if the dryer is wired as described

and the compressor is not running.

IMPORTANT

Operating this dryer on the 4 minute cycle will more than

double the wear on the dryer components. To reduce wear on

the dryer, operate the dryer on the 10 minute cycle if the -40

O

F

dew point is acceptable.

7.2 SETTING THE CYCLE TIME

Reference Figure 4B:

The setting for the time cycle is a 5 min/half cycle. For the half cycle

time setting, the switches indicated for DS1 (2, 5, 7, & 8) as shown in

the CYCLE TIME DETAIL have been factory set by pushing the

switches up. The values for these switches are (256, 32, 8, & 4) sec.,

so when added together equal 300 sec or 5 min. WE DO NOT

RECOMMEND

a time cycle setting below 2 min/half cycle. For this

half cycle time setting, the switches that need to be pushed up are DS1

(4, 5, 6, & 7)

there values are (64, 32, 16, & 8) sec. so when added

together equal 120 sec or 2 min.

The setting for the pressurization time is 20 sec. For the pressuriza-

tion time setting, the switches indicated for DS2 (2 & 4) as shown in

the CYCLE TIME DETAIL have been factory set by pushing the

switches up. The values for these switches are (16 & 4) sec., so when

added together equal 20sec. WE DO NOT RECOMMEND CHANG-

ING THIS SETTING.

The setting for the alarm time is 96 sec. For the alarm time setting,

the switches indicated for DS2 (5 & 6) as shown in the CYCLE TIME

DETAIL

have been factory set by pushing the switches up. The values

for these switches are (64 & 32) sec., so when added together equal

96 sec. WE DO NOT RECOMMEND CHANGING THIS SETTING.

NOTE: THE ALARM TIME SETTING NEEDS TO BE LESS THEN

THE HALF CYCLE TIME SETTING OR THIS WILL NEGATE

THE ALARM FUNCTION.

FIGURE 7B CYCLE TIMING CHART