Section 4 - installation, 4 pressure relief valves, 1 location – Van Air Systems HLSXG-55 User Manual

Page 5: 2 piping and ancillary equipment, 5 purge exhaust piping, 3 filters

PAGE 5

INSTALLING THE DRYER

SECTION 4

4.4 PRESSURE RELIEF VALVES

CAUTION

THESE ASME CODE VESSELS MUST BE PROTECTED BY

PRESSURE RELIEF VALVES. Refer to OSHA 1910.169 Par. b, Sub.

Par (3) and ASME Boiler and Pressure Vessel Code, Section VIII,

Division 1, UG-125 through UG-136. Also comply with all state

and local codes.

Two connections were provided in the outlet piping of the dryer for the

installation of customer supplied pressure relief valves. Reference

SECTION 3.2 for location.

4.1 LOCATION

WARNING

DO NOT INSTALL THIS DRYER IN AN ENVIRONMENT OF

CORROSIVE CHEMICALS, POISONOUS GASSES, OR

SATURATED STEAM HEAT.

Locate dryer in a protected, well vented area where ambient

temperatures are between 40

o

F and 120

o

F. Allow sufficient clearance

over and around the dryer for access to desiccant fill and drain ports

and controls.

Refer to SECTION 3.2 for dryer dimensions.

Position the dryer in the upright position on a solid, level, vibration free

surface capable of supporting the dryer’s weight.

Refer to SECTION

3.1 for dryer specifications.

The dryer should not be located in extremely dirty areas where

airborne contaminants can accumulate on the dryer. If this cannot be

prevented, the dryer should be cleaned periodically.

Once the location has been determined, place the dryer into position.

Reference SECTION 1 for handling instructions.

4.2 PIPING AND ANCILLARY EQUIPMENT

CAUTION

Make sure that the inlet gas piping is connected to the LOWER

connection of the dryer system and the outlet gas piping is connected

to the UPPER connection of the dryer system. Reference SECTION 3.2.

Make sure that the inlet and outlet piping are properly supported.

Excessive stress may cause damage and/or dryer malfunction.

Remove protective caps or covers from all piping connections before

installing this dryer.

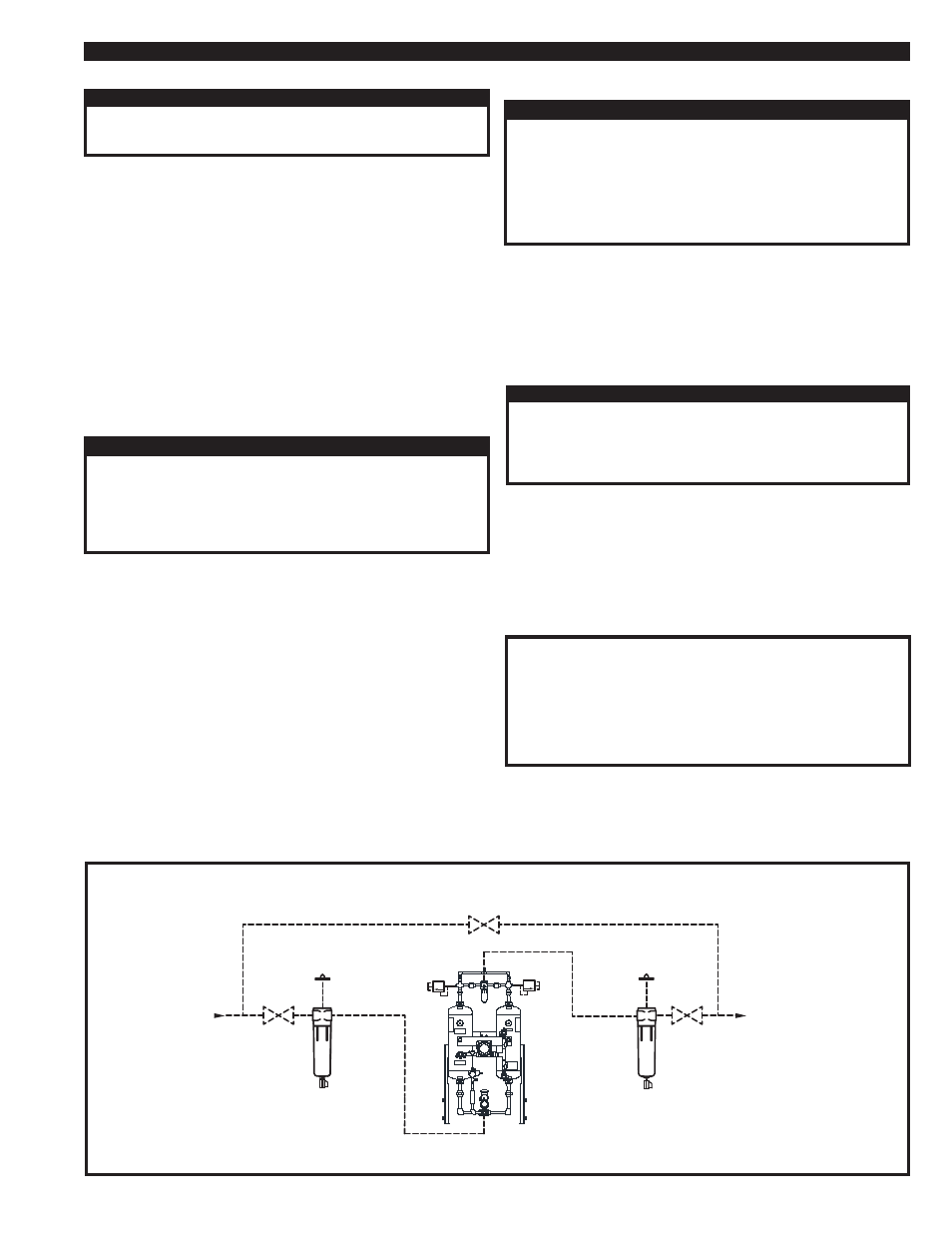

If this dryer is to be installed into an existing piping system, clean the

existing inlet piping to remove all accumulated dirt, pipe scale, etc.,

before connecting the dryer. See

FIGURE 4A for Recommended

Piping Conficuration. Make sure the inlet and outlet shutoff valves are

tightly closed before connecting to the existing piping system.

If excessive vibrations are present in the piping, install a flexible hose

between the compressor and the dryer inlet.

When installing the piping and any additional components, make sure

that adequate pipe supports are used. Excessive stress on the dryer

and components may cause damage or premature failure. Use either

overhead or stiff-leg type supports.

Make sure that the piping is correctly connected to the dryer.

Reference SECTION 3.2 for dryer dimensions and connection

locations.

4.5 PURGE EXHAUST PIPING

A 1/2" NPT female purge connection is provided on the dryer. Solenoid

valve and control line relief valve exhausts also run into this exhaust

port.

See SECTION 3.2 for location. The customer is responsible to

pipe the purge to flair or to re-entrain it to the compressor intake.

IMPORTANT

Make sure that the piping is as short as possible and does not

create back pressure on the dryer. To prevent liquid

accumulation in the piping and purge valve, the piping must be

at the same level or lower than the purge valve.

If the ambient temperature is subject to temperatures below 40

o

F,

freeze protection must be installed.

The distance will determine the size of piping that is recommended.

For distances of 10 feet or less, use piping of the same size as the

purge valves. For distances up to 20 feet, use piping one size larger

than the purge valves.

A high efficiency coalescing prefilter should be installed before the

dryer to remove lubricating oils, dust and pipe scale contamination. A

general purpose particulate afterfilter should be installed downstream

of the dryer to remove and desiccant dust. It is recommended that the

pre and after filters have pressure differential gauges to monitor ele-

ment life.

See FIGURE 4C for recommended pre and after filters.

4.3 FILTERS

CAUTION

THE DRYER IS NOT DESIGNED TO HANDLE LIQUID WATER. IF

LIQUID WATER IS PRESENT IN THE GAS SYSTEM, A

SEPARATOR WITH AN AUTOMATIC DRAIN MUST BE IN-

STALLED UPSTREAM OF THE DRYER SYSTEM TO PREVENT

FLOODING.

Make sure that the elements are installed in all filter housings

prior to start up.

FIGURE 4A RECOMMENDED PIPING CONFIGURATION AND COMPONENTS

NOTE:

Components shown here are

NOT supplied with the dryer.

MANUAL

DRAIN VALVE

DRYER

MANUAL

DRAIN VALVE

INLET

ISOLATION

VALVE

OUTLET

ISOLATION

VALVE

BYPASS VALVE

PRESSURE

DIFFERENTIAL

INDICATOR

PRESSURE

DIFFERENTIAL

INDICATOR

INLET

OUTLET

COALESCING

PREFILTER

PARTICULATE

PREFILTER

SAFETY

RELIEF

VALVE

TYP