Section 3 - specifications – Van Air Systems HLSXG-55 User Manual

Page 3

PAGE 3

3.1 DRYER SYSTEM SPECIFICATIONS

DIMENSIONS ............... See SECTION 3.2.

VESSELS (desiccant towers)

Construction ................... Manufactured to the ASME CODE, Section VIII, Division 1.

Vessels stamped "UM" symbol.

Design Pressure ............. 300 PSIG

Design Temperature ....... -20

O

F TO 200

O

F

PIPING

Threaded fittings: ANSI B16.11

Threaded unions: ANSI B16.11

Pipe: Carbon steel, Schedule 40

VALVES

Inlet ............................... 4-Way ball valve w/ actuator (Qty. 1)

Outlet .............................. Check valves (Qty. 2)

Purge .............................. Ball valve w/ actuator N.C. (Qty. 1)

Purge Metering .............. Needle valve (Qty. 1)

CONTROL GAS FILTER

Construction ................... Aluminum housing

ELECTRICAL

12V DC,3.5 Amps

CONTROL BOX

NEMA 4/7 CD

Explosion Proof (Class 1, Div 1, Groups C & D)

DESICCANT

Material ........................... Activated Alumina, 1/8" (2-5 MM) Bead type

Quantity Per Tower: ....... See

SECTION 3.2.

OPERATING CONDITIONS

Inlet Operating Pressure ................ MIN 80 PSIG ...........MAX 250 PSIG

Inlet Operating Temperature ........... MIN 40

O

F ................MAX 120

O

F

Ambient OperatingTemperature ..... MIN 40

O

F ................MAX 120

O

F

RATED INLET CONDITIONS

Inlet Flow ........................................ 79 MSCFD

Inlet Gas Pressure .......................... 100 PSIG

Inlet Gas Temperature .................... 100

O

F

Relative Humidity (saturation) ........ 100% RH

PROCESS GAS

Natural Gas

DIMENSIONS AND SPECIFICATIONS

SECTION 3

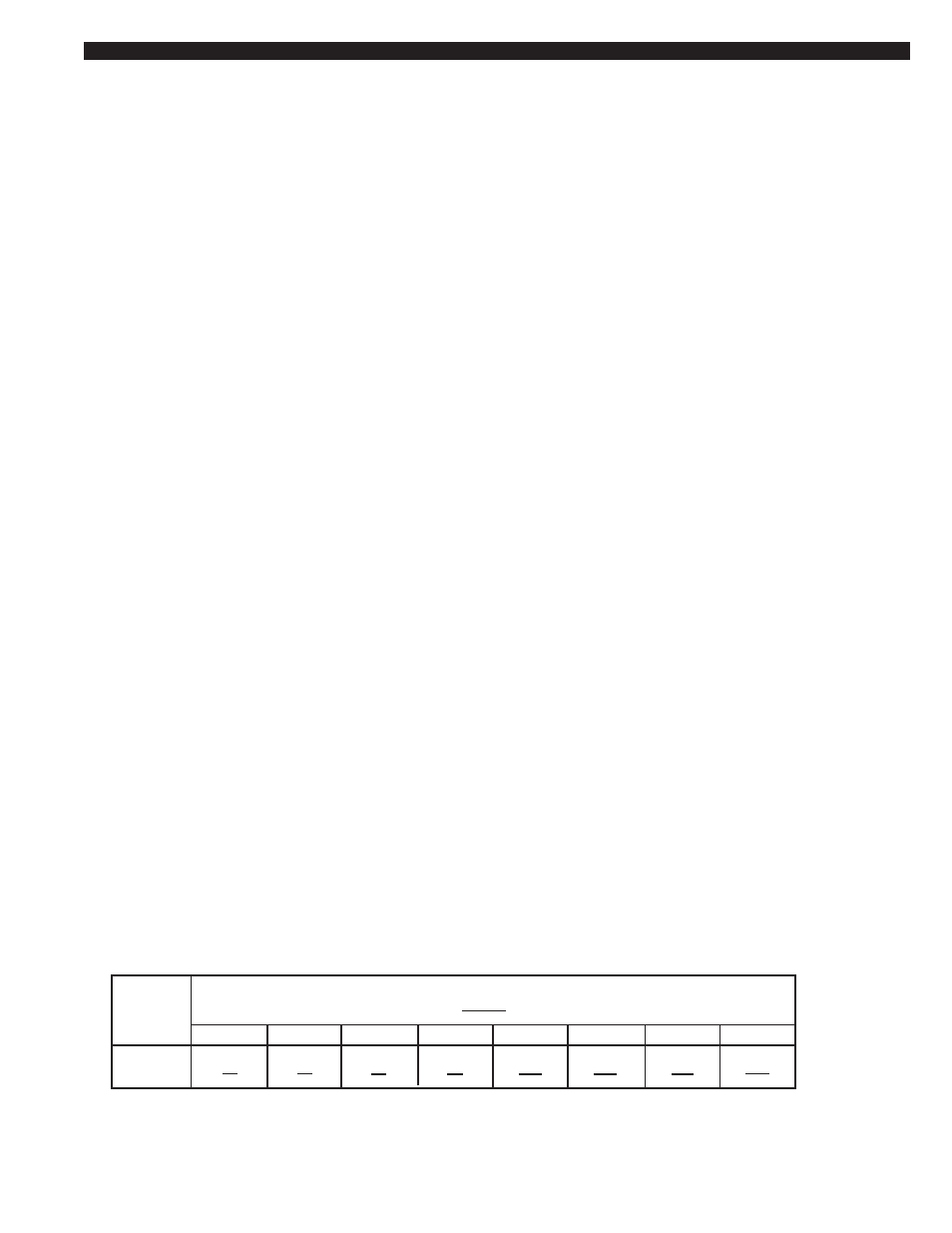

MODEL

HLSXG55

80 PSIG

65

Flow capacities at various pressures

MSCFD

100 PSIG

79

125 PSIG

87

150 PSIG

95

175 PSIG

102

200 PSIG

108

225 PSIG

114

250 PSIG

120