Van Air Systems D12-D36 User Manual

Page 5

PAGE 5

The drain line of the dryer can be remotely piped . DO NOT connect

the drain line to a pressurized line. Make sure that the line is vented

to atmospheric pressure. Any remote drain piping should be of the

same size and on the same level or lower than the drain valve.

When installing the drain line, make sure that the discharge end of the

line or valve is directed away from people and equipment.

2.2-E OPTIONAL AUTOMATIC DRAIN VALVE

The MDV-400I drain valve is recommended, other materials,sizes,

and voltages are available . Contact your local VAN AIR representative

to order.

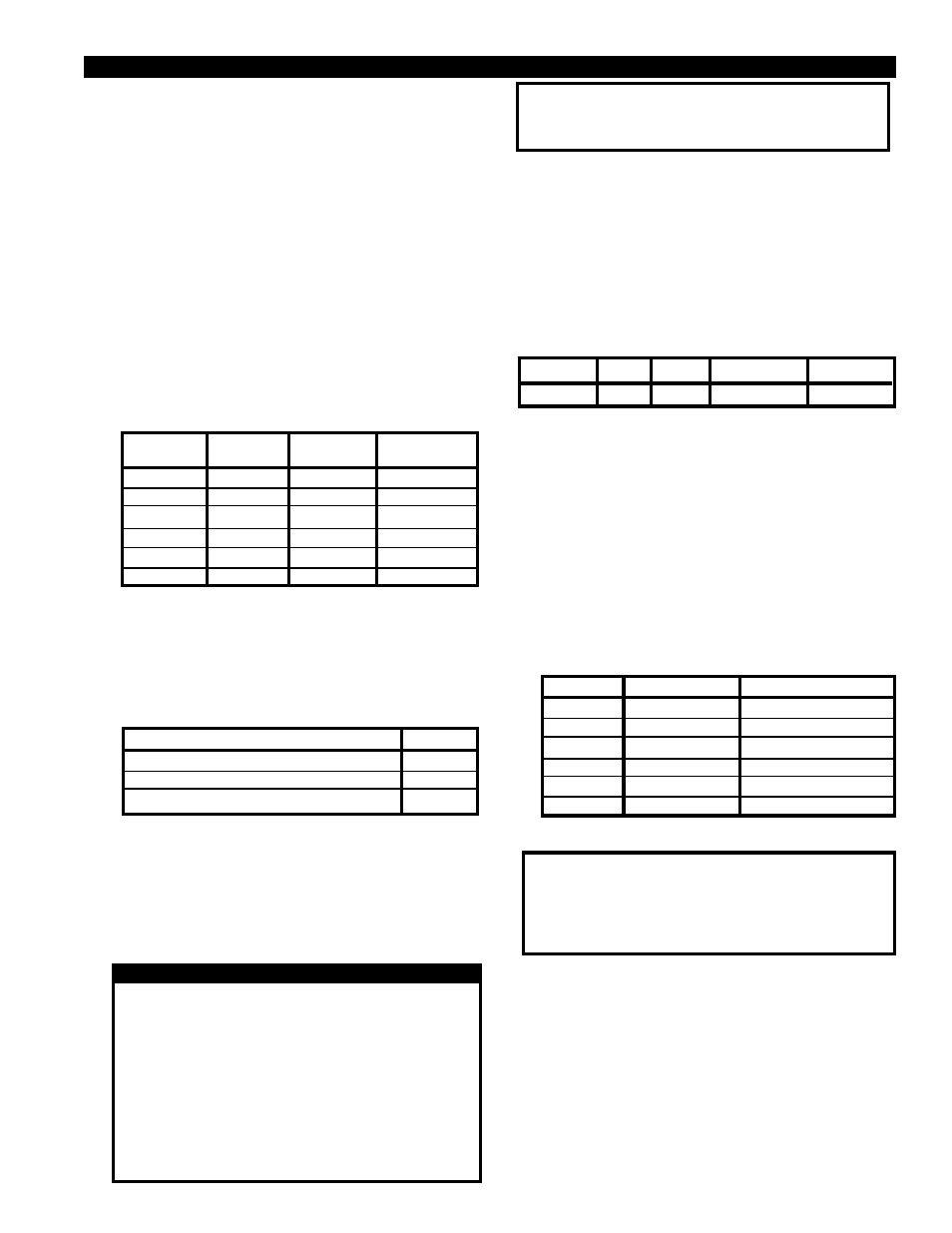

MODEL

VOLT

SIZE

MATERIAL

PART NO.

MDV-400I

115

1" NPT BRASS

39-2411121

Complete the automatic drain valve installation as shown in

FIGURE 2 and outlined in the instructions supplied with the drain.

The drain line can be remotely piped, follow the precautions as

outlined in Section 2.2-D.

2.2-F AFTERFILTER

The installation of an afterfilter prevents any accidental flow of

materials from the dryer into the downstream piping.

The afterfilter may be installed before or after the outlet isolation

valve. If the afterfilter is installed before the isolation valve, the filter

can be isolated from the air system when the dryer is isolated for

maintenance.

Below is a chart of VAN AIR recommended filters. Contact your local

VAN AIR representative to order.

IMPORTANT

The drain solution may contain lubricants. Comply with all

applicaple regulations concerning the disposal of these

chemicals.

2.2-A INLET AND BYPASS PIPING

Using Figure 3 as a reference, make the necessary piping

connections into the dryer.

Inlet and outlet isolation valves should be installed on the dryer.

These valves will aid in the start up and shutdown of the dryer. A

bypass valve and piping should also be installed. This will allow

the dryer to be taken off stream without interrupting the air system.

2.2-B OPTIONAL PRESSURE RELIEF VALVE

A pressure relief valve should be installed to conform to OSHA

safety standards. Refer to OSHA Standard Section 1910.169,

paragraph b, subparagraph 3 and any other federal, state or

local codes concerning pressure vessels.

A coupling was provided on the upper back side of the vessel for

installing the relief valve. A bushing will be necessary to reduce

the coupling to the valve inlet size. Reference FIGURE 3 for

location.

Listed below are the recommended relief valves available for

each dryer. Contact your local Van Air representative to order.

VALVE SIZE

1/2" NPT

1/2" NPT

3/4" NPT

3/4" NPT

1" NPT

1-1/4" NPT

VALVE

PART NO.

14-1462

14-1462

14-1810

14-1800

14-2204

14-2203

DRYER

CONN. SIZE

1" NPT

1" NPT

2" NPT

2" NPT

2" NPT

3" NPT

DRYER

D-12

D-16

D-20

D-24

D-30

D-36

2.2-C OPTIONAL GAUGE INSTALLATION

A coupling was provided on this dryer for the installation of a

gauge.

Three gauges are available for this dryer from your Van Air

representative.

Thread the gauge kit into the coupling provided on the lower, front

side of the vessel as shown in FIGURE 3.

GAUGE KITS

PRESSURE

TEMPERATURE

COMBINATION PRESSURE/TEMPERATURE

PART NO.

29-0252

29-0326

29-0200

NOTE: For dryer models D-12 through D-20 only, the gauge

coupling can be used for the installation of a high level alarm

instead of a gauge.

2.2-D MANUAL DRAIN VALVE

A 1" NPT brass ball valve was shipped separately with the dryer.

Install the valve on the drain line. Reference FIGURES 3 & 4 for

location.

CAUTION

DO NOT CONNECT THE DRAIN TO A PRESSURIZED LINE.

DO NOT INSTALL THE DRAIN LINE IN THE DIRECTION OF

PEOPLE AND EQUIPMENT. WHEN THE DRYER IS DRAINED

THE DRAIN SOLUTION WILL BE DISCHARGED UNDER

LINE PRESSURE. POINTING THE DRAIN IN THE DIRECTION

OF PEOPLE AND EQUIPMENT MAY RESULT IN INJURY

AND DAMAGE.

DO NOT INSTALL A FLOAT TYPE OR SOLENOID TYPE

DRAIN ON THE DRYER. THE DRAIN SOLUTION WILL

CAUSE THESE TYPES OF DRAINS TO FAIL, THUS

RESULTING IN FLOODING OF THE DRYER.

DRYER

D-12

D-16

D-20

D-24

D-30

D-36

FILTER

F200-100-1-B

F200-150-1-B

F200-265-1-1/4-B

F200-400-2-B

F200-600-3-B

F200-800-3-B

DEL-P GAUGE

PD-5

PD-5

PD-5

PD-5

PD-5

PD-5

2.2-G DESICCANT INSTALLATION

IMPORTANT

This dryer was shipped WITHOUT the desiccant installed.

The desiccant MUST BE INSTALLED before using the dryer

THE USE OF CHEMICALS OTHER THAN VAN AIR DESICCANT

WILL VOID THE WARRANTY ON THE DRYER.

The procedures for filling the dryer with desiccant are outlined in

Section 4.4 of this manual.

2.2-H HIGH LEVEL ALARM HLA-120 (P/N 26-3667)

The HLA120 high level alarm is designed to alert personnel that the

drain solution in the dryer has reached an unacceptable level. A

coupling is provided on the dryer models D-24 through D-36. For

dryer models D-10 through D-20 the gauge coupling can be used

to install the alarm instead of a gauge. Contact your local VAN AIR

representative to order.

Install the HLA120 high level alarm in the coupling as shown in

FIGURE 3 and as outlined in the instructions supplied with the

alarm.

SECTION 2

INSTALLATION