Universal Air Tools UT8750B - 5 Disc (125mm) User Manual

Putting into service air supply, Important, Operator instructions

Important

Read these instructions carefully before installing, operating,

servicing or repairing this tool. Keep these instructions in a safe

accessible place.

Includes - Foreseen Use, Work Stations, Putting Into Service, Operating,

Dismantling, Assembly and Safety Rules

Operator Instructions

Manufacturer/Supplier

Product Type

RPM

Cycles Per Min

Model No/Nos

Serial No

Product Nett Weight

lbs

Kg

Recommended Use Of

Balancer Or Support

Recommended Hose Bore

Size - Minimum

Recommended Max.

Hose Length

Ins

M/M

Ft

M

No

Page No 1

Angle Disc Grinder

10mm Dia Threaded Shaft

UT8750 - 4” Disc (100mm)

UT8750A - 4½” Disc (115mm)

UT8750B - 5” Disc (125mm)

3.87

1.76

3/8

10

30

10

12,000

Universal Air Tool Company Limited

Unit 8

Lane End Industrial Park

High Wycombe

Bucks

HP14 3BY

Work Stations

The tool should only be used as a hand held hand operated tool. It is

always recommended that the tool is used when standing on a solid

floor. It can be used in other positions but before any such use the

operator must be in a secure position having a firm grip and footing and

be aware of the safety rules to be obeyed when using the sander.

Foreseen Use of Tool

This right angle grinder is designed to be used with reinforced resin

bonded depressed centre grinding wheels that have a permitted

rotational speed in excess of 12,000 RPM. See parts lists for details of

available wheel sizes.

The tool is designed to be used for light grinding and dressing of welds,

etc. but not for cutting off. The grinder must never be used if a wheel

guard (disc cover) item (3) is not fitted.

Tel No

Fax No

(01494) 883300

(01494) 883237

Noise Level

Sound Pressure Level 82.9 dB(A)

Test Method

Tested in accordance with Pneurop

test code PN8NTC1 and ISO Standard 3744

Vibration Level

Test Method

Tested in accordance with ISO

standards 8662/1 & 8662/4

5.1 Metres / Sec²

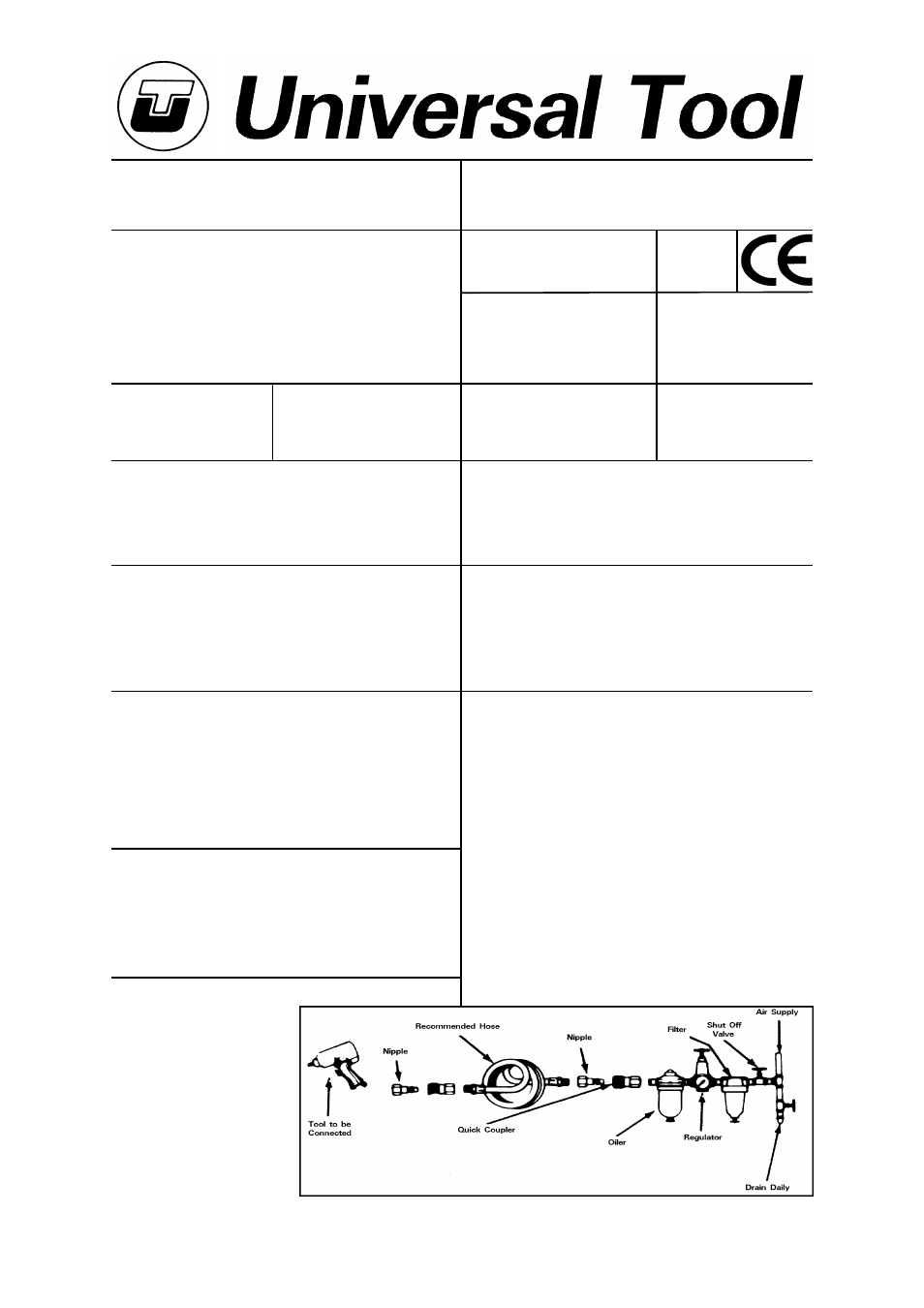

Putting Into Service

Air Supply

Use a clean lubricated air supply

that will give a measured air

pressure at the tool of 90 p.s.i./6.3

bar when the tool is running with

the trigger/lever fully depressed.

Use recommended hose size and

length. It is recommended that the

tool is connected to the air supply

as shown in figure 1. Do not

connect the tool to the air line system without incorporating an easy

to reach and operate air shut off valve. The air supply should be

lubricated. It is strongly recommended that an air filter, regulator,

lubricator (FRL) is used as shown in Figure 1 as this will supply

clean, lubricated air at the correct pressure to the tool. Details of

such equipment can be obtained from your supplier. If such

equipment is not used then the tool should be lubricated by

shutting off the air supply to the tool, depressurising the line by

pressing the trigger on the tool. Disconnect the air line and pour into

the intake bushing a teaspoonful (5ml) of a suitable pneumatic

motor lubricating oil preferably incorporating a rust inhibitor.

Reconnect tool to air supply and run tool slowly for a few seconds

to allow air to circulate the oil. If tool is used frequently lubricate on

daily basis and if tool starts to slow or lose power.

It is recommended that the air pressure at the tool whilst the tool is

running is 90 p.s.i./6.3 bar. The tool can run at lower and higher

pressures with the maximum permitted working air pressure of

100 p.s.i./7 bar.

Personal Safety Equipment

Use - Safety Glasses

Yes

Use - Safety Gloves

Yes

Use - Safety Boots

Use - Breathing Masks

Yes

Use - Ear Protectors

Yes

Air Pressure

Recommended Working

6.3

bar

90

PSI

Recommended Minimum

n/a

bar

n/a

PSI

Maximum

7.0

bar

100

PSI