Operating, Dismantling & assembly instructions, Reassembly – Universal Air Tools UT5735 User Manual

Page 2

Operating

Select a suitable mounted point that has a free running speed

higher than the maximum running speed marked on the tool.

Make sure that the diameter of the shank exactly matches the

diameter of the collet mounted in the grinder. There are four

standard sizes of collet available for use with this grinder, i.e.

1) - 1/4" Dia (0.250ins) (6.35mm)

2) - 6mm (0.236ins)

3) - 1/8" (0.125ins) (3.175mm)

4) - 3mm (0.118ins)

Never try to force a 1/4" diameter shank into a 6mm collet or a

1/8" diameter shank into a 3mm collet. Never try to close a

1/4" diameter collet to secure a 6mm shank or a 1/8" diameter

collet to secure a 3mm diameter shank. Always match correctly

the shank size to the collet size. If uncertain, have parts

measured by a competent person.

Push the shank as far as possible into the collet and tighten the

collet nut using the spanners provided on the collet nut and

output spindle.

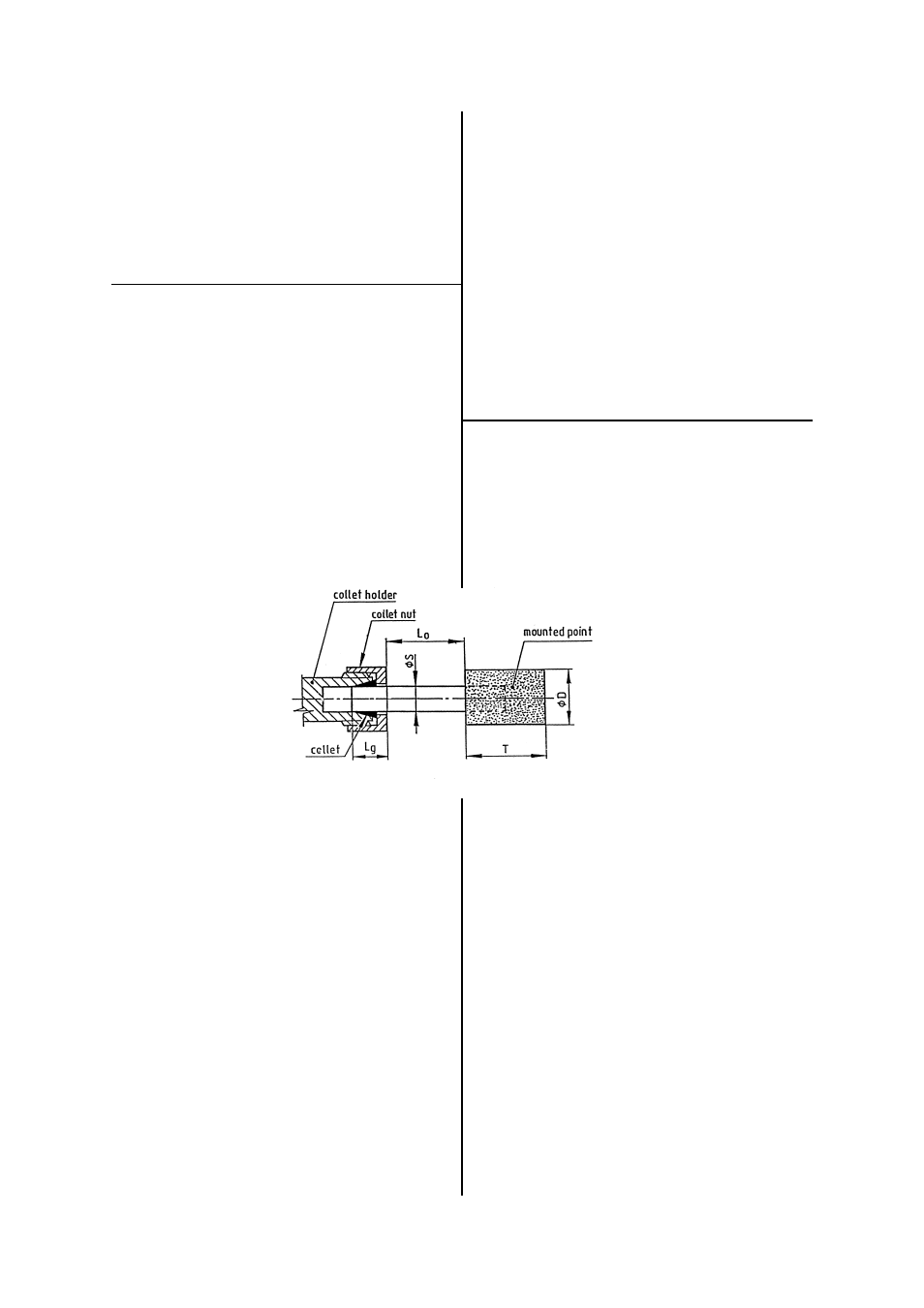

The shank of the mounted point

may be pulled forward from the

maximum insertion length but

always ensure a minimum

gripping length of not less than

10mm - See Figure 2.

Be aware that the allowed

running speed of the mounted

point is lowered because of an

increase in the length of the

shank between the end of the

collet and the body of the

mounted point. This distance is

shown in Diagram 2 as "LO"

and is called the overhang. The

information with respect to mounted point size, permissible

running speed and reduction in running speed due to an

increase in overhang is available from the supplier of the

mounted point.

If the increase in overhang for access reasons takes the

permissible running speed of the mounted point below the free

running speed of the grinder select a smaller diameter mounted

point.

The fitting of the mounted point should be done by a trained

operator.

When first starting the grinder with a new wheel fitted, the

grinder should not be near other persons and be held in a

protected area, i.e. under a bench and run for a few seconds.

This will protect personnel from possible effects of damage to

the mounted point before it was fitted to the grinder i.e. wheel

breakage.

Always use eye protection and wear protective gloves if there

are sharp edges in the work area. The tool and the grinding

process can create a noise level such that the use of ear

protectors is advised.

If the grinding process creates a dust then use a suitable

breathing mask.

Check that the material being worked will not cause harmful

dust or fumes. If this is so then special breathing masks may be

required.

Dismantling & Assembly Instructions

Disconnect from air supply.

Remove collet nut (25) and collet (24).

Unscrew coupling nut (14) and remove extended front end

assembly complete.

To dismantle extended front end assembly, coupling nut (26)

may be unscrewed from extension housing (23) [left hand

thread].

Pull out motor assembly.

Grip the motor assembly by hand or in a

soft jaw vice and tap the rear end of the

rotor (15) through the rear end plate (14)

and bearing (13). Tap rear end bearing

(13) out of rear end plate (14). Remove

4 off rotor blades (16) and remove

cylinder (18). Pins (17) may be removed

from cylinder (18). The rotor (18) can

then be tapped through front end bearing (20), front end plate

(19) and spacer (12). Front end bearing (20) can be tapped out

of front end plate (19).

Clean and examine parts for wear and replace only with

manufacturer supplied parts. Ensure that the faces of end plates

(14) and (19) that abut cylinder (18) are flat and free from burrs.

Lap on a flat, very fine grade of abrasive paper if necessary.

Check O-Rings for cuts and wear.

Reassembly

Lightly coat parts with oil, pack bearings with a lithium or

molybdenum based general purpose grease and reassemble in

the reverse order.

Note:- when reassembling the motor assembly, ensure that pins

(17) in cylinder (18) are correctly located in the holes in front end

plate (19) and rear end plate (14). Also ensure that pin (17)

located in the outside diameter of front end plate (19) locates in

the slot in motor housing (33).

Check the collet assembly, the function of the safety lever and

that the free speed is correct before returning to service. Ensure

that the air regulator is in the maximum open position before

making a speed check.

pour into the intake bushing a teaspoonful (5ml) of a suitable

pneumatic motor lubricating oil preferably incorporating a rust

inhibitor. Reconnect tool to air supply and run tool slowly for a

few seconds to allow air to circulate the oil. If tool is used

frequently lubricate on daily basis and if tool starts to slow or

lose power.

It is recommended that the air pressure at the tool whilst the

tool is running is 90 p.s.i./6.3 bar. The tool can run at lower and

higher pressures with the maximum permitted working air

pressure of 100 p.s.i./7.0 bar.

Page No 2

If the grinder vibrates when first fitting a mounted point or during

operation, remove from service immediately and correct fault

before continuing to use.

Do not apply excessive pressure as this will reduce the cutting

efficiency and can bend the shank of the mounted point causing

vibration and the possibility of breakage. Apply light loads to

allow the wheel to cut.

Handle the grinder with care. If the grinder is dropped, carefully

check the mounted point for damage, i.e. cracks, chipping and

start for the first time as for fitting a new wheel i.e. under a

bench.

Never exceed the maximum air pressure. If there is this

possibility always use this grinder with a pressure reducing valve

fitted in the supply line. Your supplier will advise of suitable

equipment.

This grinder is fitted with a speed regulator and the speed may

be reduced by rotating air regulator (41) . When making speed

checks always rotate the air regulator to the position to give the

highest maximum speed.

D

= diameter of mounted point

T

= length of mounted point

Lo

= overhang

S

= diameter of shank

Lg

= gripping length

Figure 2. Gripping length of collet and chuck