Spray gun paint patterns, Faults and remedies, Faulty spray patterns – Universal Air Tools UT57A User Manual

Page 6: Spitting, Correct spray patterns, Top heavy spray, Bottom heavy spray

Page No 6

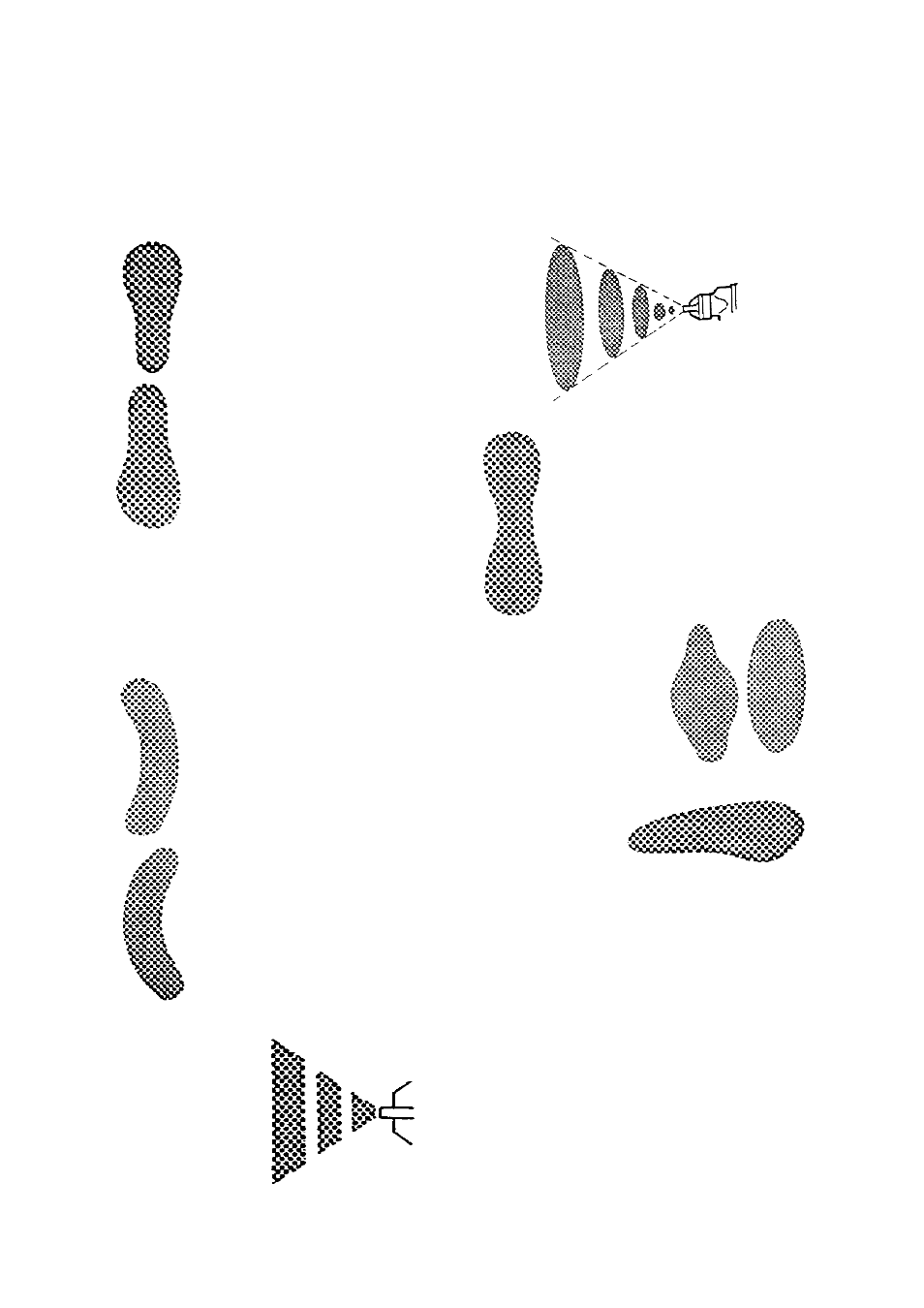

Spray Gun Paint Patterns

Faults and Remedies

Top Heavy Spray

Cause

a)

Wing holes partially obstructed

b)

Damaged or obstruction of material

nozzle tip

c)

Air cap or material nozzle not seating

correctly due to dirt or damage

Faulty Spray Patterns

Bottom Heavy Spray

Cause

a)

Wing holes partially obstructed

b)

Damage or obstruction to bottom of

material nozzle tip

c)

Air cap or material nozzle not seating

correctly due to dirt or damage

Remedy

Turn the air cap through 180

°. If defective pattern is reversed, fault is

due to air cap

Remove and clean air cap

If defective pattern does not reverse then fault is with the material nozzle

Remove nozzle and clean

Do not use metal objects to clear holes

Cause

a)

Dirt in material nozzle or a loosely fitted

nozzle/air cap

b)

Dried out gland packing around

material needle valve

c)

Loose fitting nut or fractured feed tube

in container

d)

Insufficient material in container

e)

Obstructed fluid passageways

Remedy

a)

Clean and refit tightly

b)

Lubricate and tighten (if

necessary

replace

gland packing)

c)

Tighten or replace

d)

Replenish material

e)

Clean

Spitting

Cause

a)

Air hole in either wing of air cap restricted

or blocked allowing full pressure of air on

the other side to force the spray pattern in

direction of restricted or blocked side

b)

Material nozzle tip damaged or having

particles of dirt or dried paint on one side

Remedy

As above

Do not use metal objects to clear holes

Air in material

passages

Correct Spray Patterns

The spray pattern is

variable from round to fan

with all patterns in

between

Cause

a)

Too high an

atomising

air pressure

b)

Attempting

to obtain a

too wide fan

spray with

thin material

Remedy

Reducing air pressure will cure

cause (a)

To correct cause (b) open

material control to fully open

position. At same time reduce

width of spray pattern

If material is being pressure fed,

increase pressure on container

to give increased material flow

Cause

A fan spray pattern that is heavy in the

middle or a pattern that has an

anatomised “salt & pepper” effect

indicates too low an atomising

pressure

Remedy

Increase air pressure from your air

supply. Correct air pressures are

discussed elsewhere in this booklet

Cause

Dried material around nozzle tip

restricts the passage of atomising air

at one point through the centre

opening of air cap and results in this

pattern being obtained. Can also be

caused by a loose fitting air cap

Remedy

If dried material is causing

the trouble, remove air cap

and wipe off material tip,

using a rag wetted with

thinners

Tighten air cap