Tilton Floor-Mount (98-1207) User Manual

Installation instructions, 900 series floor-mount 3 pedal assembly, Description

Description

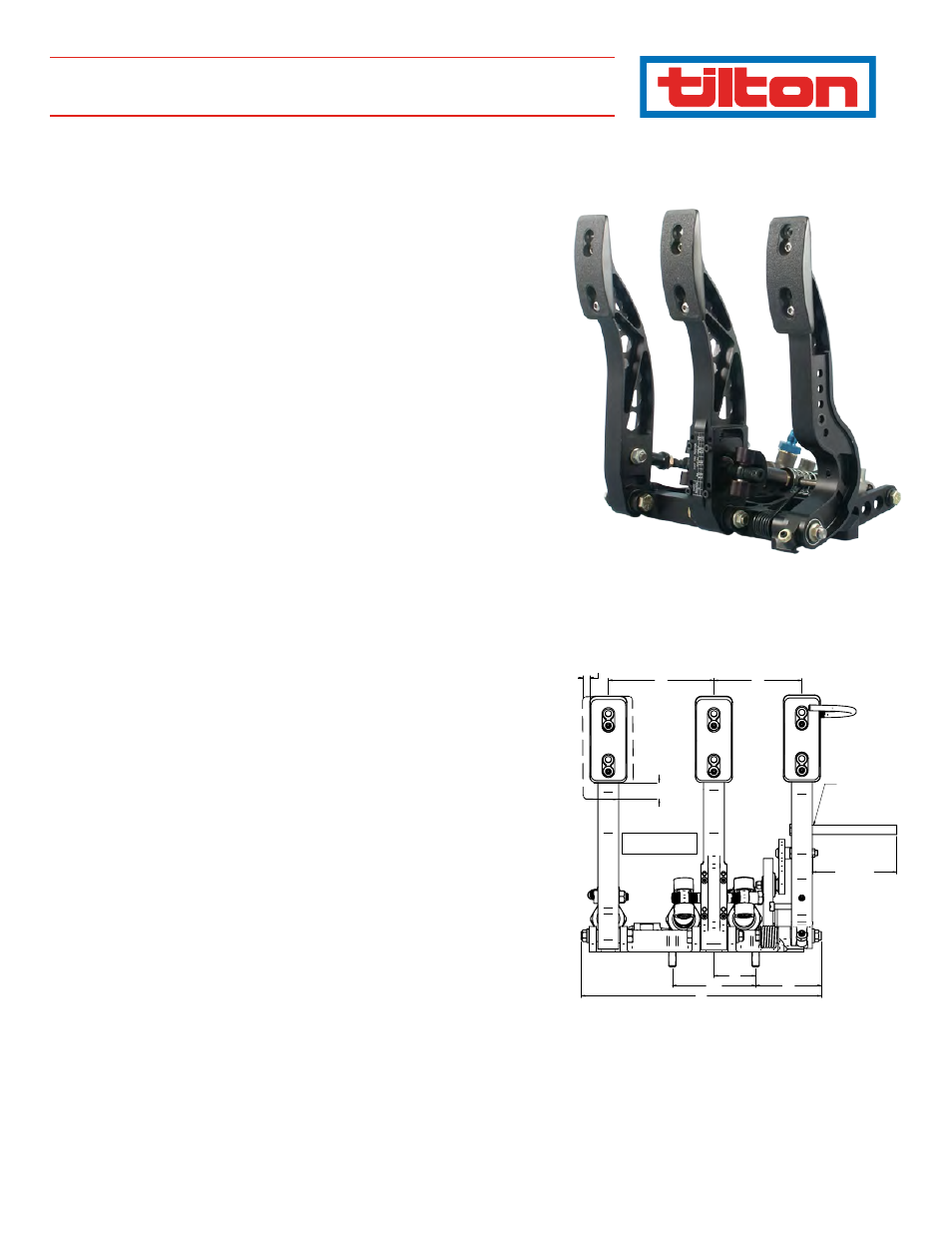

Minimizing friction and flex in the pedal assembly and the master cylinders maximizes driver

control. The Tilton floor mount pedal assembly with forward mounted pivot type master

cylinders effectively handles these critical issues. In addition this assembly is highly adjust-

able for different drivers and tracks, easy to install and maintain, and does all of this in a very

lightweight package.

Master cylinDer & peDal asseMbly installation

1. A pedal assembly can only be as rigid as its mounting system in the car.

Flex in the supporting structure reduces braking control as much as air in the lines. See the

drawing on page 4 for the mounting bolt pattern. Multiple holes in two tubes running fore/aft

in the car can allow multiple mounting positions.

2. Select the brake pedal pivot position (high or low motion ratio).

The overall pedal ratio is dependent on the pivot position combined with the foot pad

position, and the ratios are marked on the brake pedal. Tighten the four fasteners to

46 in-lbs using a 3mm hex wrench.

3. The balance bar clevises are of two different lengths; The longer clevis is to be used with

the master cylinder for the front brake system and should stay on the right-hand side of

the brake pedal. This configuration ensures the best remote adjuster cable clearance to

the throttle pedal.

4. Set the center-to-center distance on the two balance bar clevises at 2.60". A good place to

start is with both clevises equally spaced from the pedal (middle balance bar position).

5. Remove the long bolt that mounts the three master cylinders. Remove the four master

cylinder spacers from the frame.

6. Reinstall the two center master cylinder spacers in the frame. A small amount of RTV will

keep the spacers in place during assembly.

7. Install the master cylinders. It is best to install the master cylinders on the pedal assembly

before placing the assembly in the car. Reinstall the mounting bolt through the three

master cylinders, and tighten the nut to 120 in-lbs.

8. Thread the three pushrods into the clevises .710" (about seventeen (17) revolutions).

This will position the pedals as shown in the drawings. Final pedal position adjustment

will be made later.

9. Since the brake pushrods are threaded equal amounts and the clevises have two different

lengths, the balance bar will be at a 5˚ angle. This is by design and will be addressed in the

Pedal Positioning section.

10. Mount the pedal assembly into the car. Be sure to use high quality 5/16" or 8mm Allen

head bolts of the appropriate length with a supplied AN washer under the head of each

bolt.

Note:

For clearance reasons, Allen mounting bolts must be installed with the

head recessed in the counterbore of the frame. Do not be tempted to use

a large OD washer and a hex bolt that will not sit in the counterbore of the

frame, as interference to critical moving parts will occur.

900 Series Floor-mount 3 Pedal Assembly

INSTALLATION INSTRUCTIONS

98

-12

07

3.600

BILLET ALUMINUM PEDALS ARE

OPTIMIZED FOR STRENGTH,

WEIGHT AND STIFFNESS

4.56

3.65

CUT TO LENGTH

AS SUPPLIED

10.4

2.84

1.80

FOOT PAD SIDE ADJUSTMENT: THREE POSITIONS, .290 INCREMENTS

FOOT PAD HEIGHT ADJUSTMENT

ALL 3 PEDALS, .750 TOTAL

FOUR POSITIONS, .250 INCREMENTS

THROTTLE CABLE STANDOFF

FOR REAR ENGINE CARS.

UNFINISHED END CAN BE MODIFIED

BY CUSTOMER TO ACCEPT A

VARIETY OF CABLE ATTACHMENTS

3.80