Installation – Tilton Brake Proportioning Valve (98-1261) User Manual

Page 2

InstallatIon

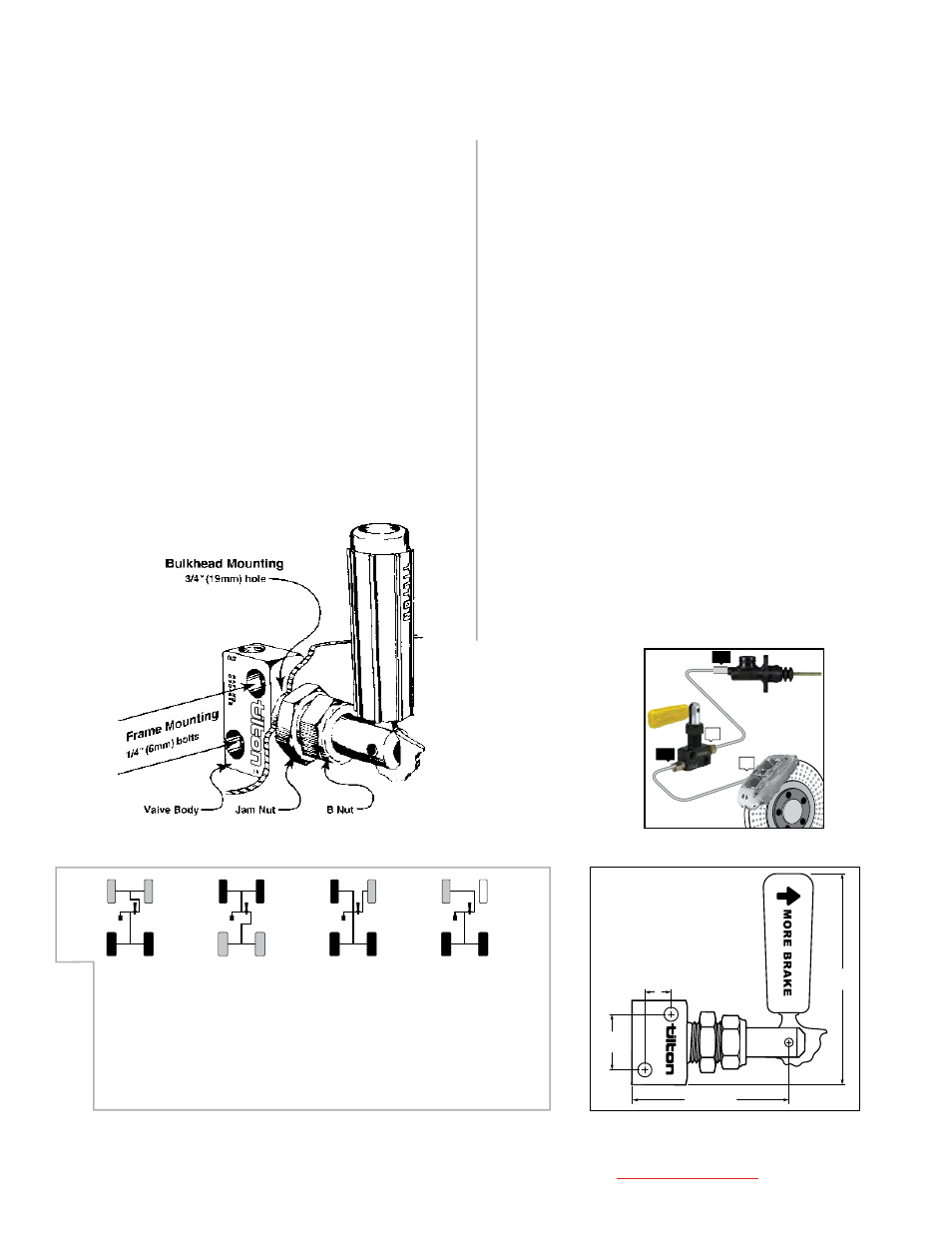

Select either the frame or bulkhead mounting style and follow the steps below:

Frame mountIng

1. Select a location for frame mounting the proportioning valve that allows

easy access to the adjusting handle/knob.

2. Make sure that the location allows room for the hydraulic lines and access

for servicing.

3. Locate and mark the location of the mounting holes on the frame refer-

ring to Diagram 4.

4. Drill two 9/32" (7mm) diameter holes in the marked locations. Debur both

of the drilled holes.

5. Test fit the valve in the prepared location and select the proper mounting

hardware. Use two 1/4" (6mm)

diameter socket head cap screws with locknuts. The length will be deter-

mined by your application.

6. Select the routing of the hydraulic lines carefully and avoid any heat

sources such as the exhaust pipes and

manifolds.

7. Refer to Diagram 2 and connect the outlet of the master cylinder to the

inlet of the proportioning valve. The outlet of the proportioning valve is

connected to the line leading to the caliper(s).

BulkHead mountIng

1. Select the location for bulkhead mounting the proportioning valve that

allows easy access to the adjusting handle (knob).

2. Make sure that the location allows room for the hydraulic lines and access

for servicing.

3. Locate and mark the location of the mounting hole on the frame referring

to Diagram 1.

4. Cut, drill or punch a 3/4" (19mm) diameter hole in the marked location.

Debur the hole.

5. Refer to Diagram 1 and loosen the B-nut on the valve body and carefully

remove the handle assembly (adjusting knob) from the valve body.

6. Refer to Diagram 1 and loosen and remove the jam nut.

7. Test fit the valve in the prepared location by sliding the valve body

through the hole in the bulkhead.

8. Secure the jam nut and insert the handle assembly (adjusting knob) into

the valve body.

9. Rotate the handle assembly into the desired position (Lever-type). Tighten

the B-nut and verify the location is suitable for ease of adjustment and

servicing. Make sure that the B-nut does not touch the jam nut. Other-

wise, the valve handle may not be held in its proper position in the valve

body.

10. Select the routing of the hydraulic lines carefully and avoid any heat

sources such as the exhaust pipes and manifolds.

11. Refer to Diagram 2 and connect the outlet of the master cylinder to the

inlet of the proportioning valve. The outlet of the proportioning valve is

connected to the line leading to the caliper(s).

Diagram 2 - Flow Diagram

Diagram 4 - Overall Dimensions

(Handle shown in Position 1, referring to Chart 1)

3.98"

(102mm)

.50" (12.8mm)

3.00" (122mm)

1.00"

(25.4mm)

OUT

IN

Diagram 3 - Typical Applications

Diagram 1 - Mounting Diagram

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

Reduced front

• Rally

• Dirt

• Off road

• Stadium racing

Used when the front tire

needs more adhesion for

steering, as well as in loose

gravel conditions.

Reduced rear

• Road racing

• Street rods

• Trucks

• Oval Track

Used to compensate for fuel

load or weight changes, de-

teriorating rear tire adhesion,

and brake systems with only

one master cylinder

Reduced right front

• Dirt

• Asphalt

Used to decrease out- side

front corner braking, which

increases turn in and reduces

understeer. Used to compen-

sate for track conditions or

deteriorating chassis setup.

Reduced left, no right

front

• Dirt racing

• Midget

• Sprint

Used to decrease in- side

front corner braking, which

decreases turn in and reduces

oversteer. Usually used on the

inside front with twin calipers

on the rear.

Front

Rear

OUT

IN

IN

OUT