Check valve assembly replacement, Troubleshooting, Refer to diagram 2 for the part numbers) – Tilton Standard Oil Cooler Pump (98-1901) User Manual

Page 2: Tilton engineering, inc

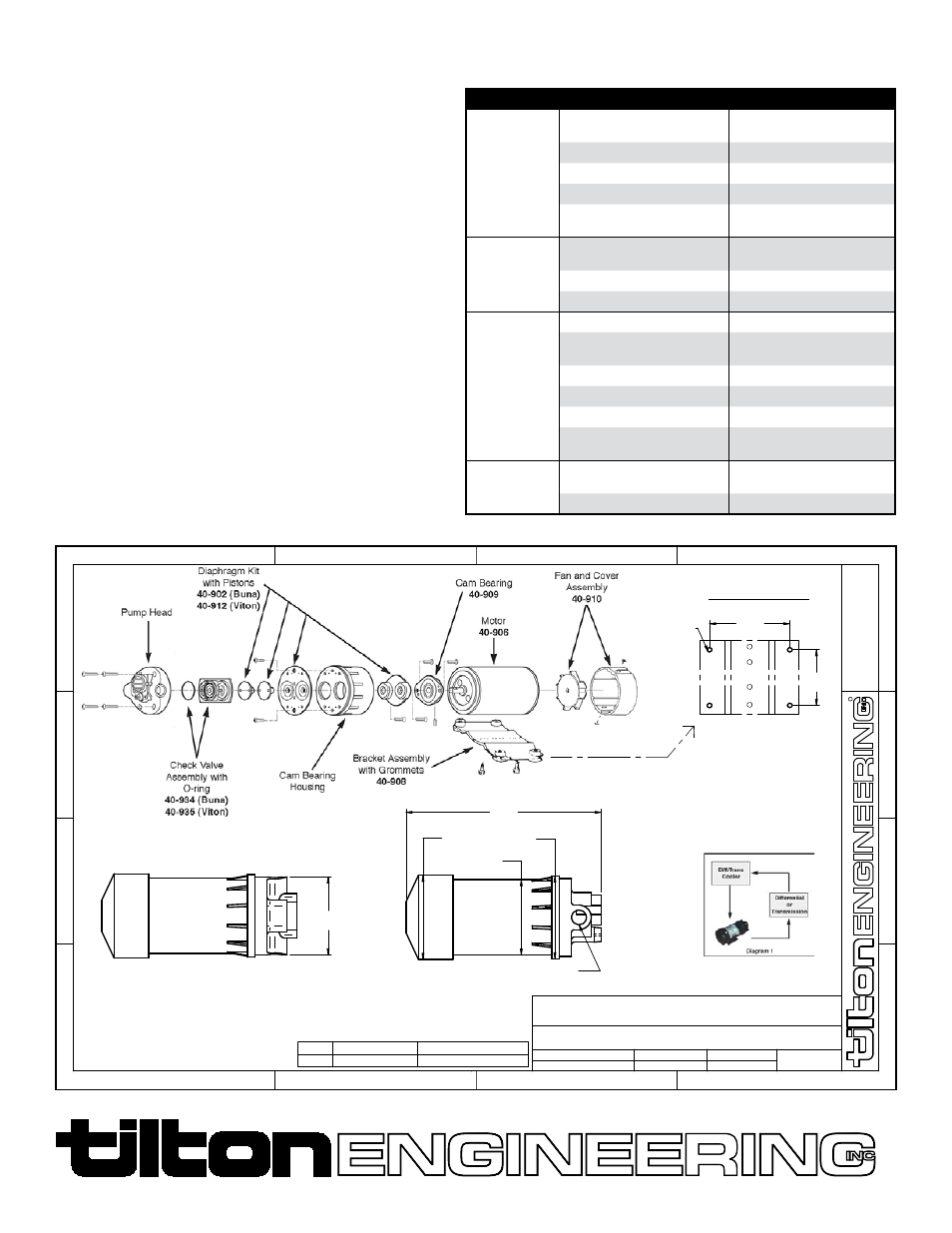

CHeCk valve assembly rePlaCement

(Refer to Diagram 2 for the Part Numbers)

1. Mark a line at the joint between the pump head and the cam bearing

housing and use this line when assembling.

2. Pay particular attention to the orientation of the pump head inlet and

outlet lines and the check valve.

3. Loosen and remove the four upper Phillips head screws that retain the

pump head assembly.

4. Remove the pump head assembly.

5. Carefully remove and set aside the old check valve body, which

includes the old o-ring.

6. The Tilton Differential Pumps (P/Ns 40-524 & 40-525) use the o-ring

that is supplied. The ring seal is not used.

7. Place the new o-ring into the new check valve body.

8. Insert the new check valve body with o-ring installed into the pump

head.

9. Place the pump head onto the cam bearing housing.

10. Align the marks that were made on the body in step #1.

11. Insert and tighten the four Phillips head screws.

12. Temporarily supply 12-volt DC power to the pump and check operation of

the pump before installing it into the vehicle.

troublesHootIng

TITLE:

25 EASY STREET, P.O. BOX 1787, BUELLTON, CA 93427 805/688-2353

DRAWN BY

CHKD

SCALE

DATE

P/N

SHEET OF

DWG

TILTON ENGINEERING, INC.

FAX 805/688-2745

: 1

TRANSMISSION/DIFFERENTIAL OIL COOLER PUMP

REED

02/22/08

1

1

5286

AVAILABLE WITH BUNA OR VITON RUBBER DIAGHRAM

SEE TABLE

3

4

2

1

C

D

B

A

"T

hi

s

doc

ument

contai

ns

pr

opr

iet

ar

y

infor

m

ati

on

of

TI

LT

ON

EN

GIN

EER

IN

G,

IN

C

.,

and

its

re

cei

pt

or

pos

ses

ion

do

es

not

conv

ey

the

right

s

to

repr

oduc

e,

di

sc

los

e

its

c

ont

ents

, or

to

manufac

tur

e,

us

e

or

s

el

l any

thi

ng

it

may

des

cr

ib

e.

R

epr

oduc

tion,

di

sc

los

ur

e,

or

us

e

wi

thou

t s

pec

ifi

c

wr

itten

author

iz

ati

on

of

TI

LT

ON

EN

GIN

EER

IN

G

IN

C

. i

s

str

ict

ly

for

bi

dd

en."

R

1

Drill Hole

O

3/16", 4 PL.

3.25

(82.55)

2.25

(57.15)

MOUNTING HOLE DIMENSIONS

40-524 COOLER PUMP, BUNA FOR NON-CORROSIVE FLUIDS

40-525 COOLER PUMP, VITON

FOR CORROSIVE FLUIDS

7.9

(200.7)

3.4

O

(86.4)

3.05

O

(77.5)

3/8 NPT, 2 PL.

3.35

O

(85.1)

3.15

(80.0)

25 Easy Street • Box 1787 • Buellton, CA 93427 • USA • (805) 688-2353 Fax (805) 688-9407

98

-19

01

Diagram 2

Symptom

Possible causes

action to take

Motor runs,

no discharge

Restricted intake or

discharge lines

Restricted intake or

discharge lines

Air leak in intake line

Check for leaks

Punctured pump diaphragm

Disassemble and inspect

Crack in pump housing

Inspect for cracks

Ensure correct power polarity

Check fuse, power switch

and polarity

Motor fails to

turn on

Pump or equipment not wired

correctly

Check fuse, power switch

and polarity

Defective motor

Check for motor rotation

Blown fuse or switch is off

Check fuse and power

Low flow and

pressure

Air leak in intake line

Check for leaks

Accumulated debris inside pump/

plumbing

Disassemble and inspect

Worn pump bearing

Disassemble and inspect

Punctured pump diaphragm

Disassemble and inspect

Defective motor

Check for motor rotation

Insufficient voltage to pump

Measure supply voltage, must be

> 12-volt DC

Pulsating

flow-pumping

cycle on/off

Restricted pump delivery

Check discharge lines, fittings

for blockage

Undersized line to intake of pump

Use only 3/8” NPT fittings