Tilton 4.5″ Carbon Clutches (98-1302) User Manual

Page 2

Tilton Engineering, Inc. 25 Easy Street • PO Box 1787 • Buellton, CA 93427 • www.tiltonracing.com

MaIntenance

1. Thicker replacement pressure plates are supplied to compensate for clutch

wear. The pressure plates are supplied in thickness increments of .020" (.5 mm).

However, the clutch is usually capable of withstanding .025" (.6 mm) or more

wear before clutch slippage will occur. It is important to let the clutch go through

the entire .020" (.5 mm) of wear before installing the next thicker pressure plate

or clutch release will be a problem. The most accurate method is to measure the

thickness of the individual plates and compare them to the dimensions of the

plates listed on the build sheet supplied with the clutch. Once .020" (.5 mm) of

total clutch plate wear is achieved it is time to switch to the next thickest pressure

plate. The thickness is engraved on the pressure plate in thousandths of an inch.

The third pressure plate (if included) is installed after .040" (1.0 mm) wear. Once

you have gone through the entire wear range of the pressure plates, return the

clutch to Tilton for a rebuild.

2. Check the clearance between drive hub fingers and the slots in the driven plates.

The slots must not be more than .020" (.5 mm) wider than the drive hub’s fingers.

This is best checked with a feeler gauge. Premature wear of the slots is usually an

indication of input shaft misalignment with respect to the crankshaft.

3. Check hub float. With the clutch installed on the flywheel the drive hub should

be able to float forward and backward at least .010" (.25 mm) on the input shaft.

Once the axial float disappears the clutch will start to slip.

4. Check for signs of excessive heat. A blue-colored hub is a sign of high tempera-

tures from a clutch having been slipped excessively. High temperatures can cause

the spring to lose clamp load. Send the assembly back to Tilton for inspection if

damage is suspected.

5. Increased wear at the release bearing contact area is a sign of a heavy left foot or a

bearing that needs to be replaced. Many clutches have been lost to the failure of a

$30 bearing that was run one race too many.

6. Whenever inspecting a clutch, be sure to replace all of the plates in the same posi-

tion and orientation in which they were originally installed. Alignment marks can

be found on the plates and the clutch cover.

7. Blowing out a clutch cover with an air nozzle is acceptable. Cleaning the clutch

cover in a solvent tank is not recommended as this removes the grease from the

internal diaphragm spring pivot locations.

8. Always start a 12 or 24-hour race with a new or freshly rebuilt clutch.

9. If the clutch is used too far beyond recommended wear (pressure plate change)

intervals, the clutch may slip excessively and result in total clutch loss. Carbon

clutches are rebuilt at Tilton and can be sent directly or through your distributor.

If you send it directly, call first to obtain a Returned Merchandise Authorization

(RMA) number. It is to your benefit to supply information on the type of car, type

of racing, and any other particulars concerning the reason for the return.

You will be provided with a quote before work is performed. All rebuilt clutches

are tested for clean release, torque capacity, and clamp load before being

returned to the customer.

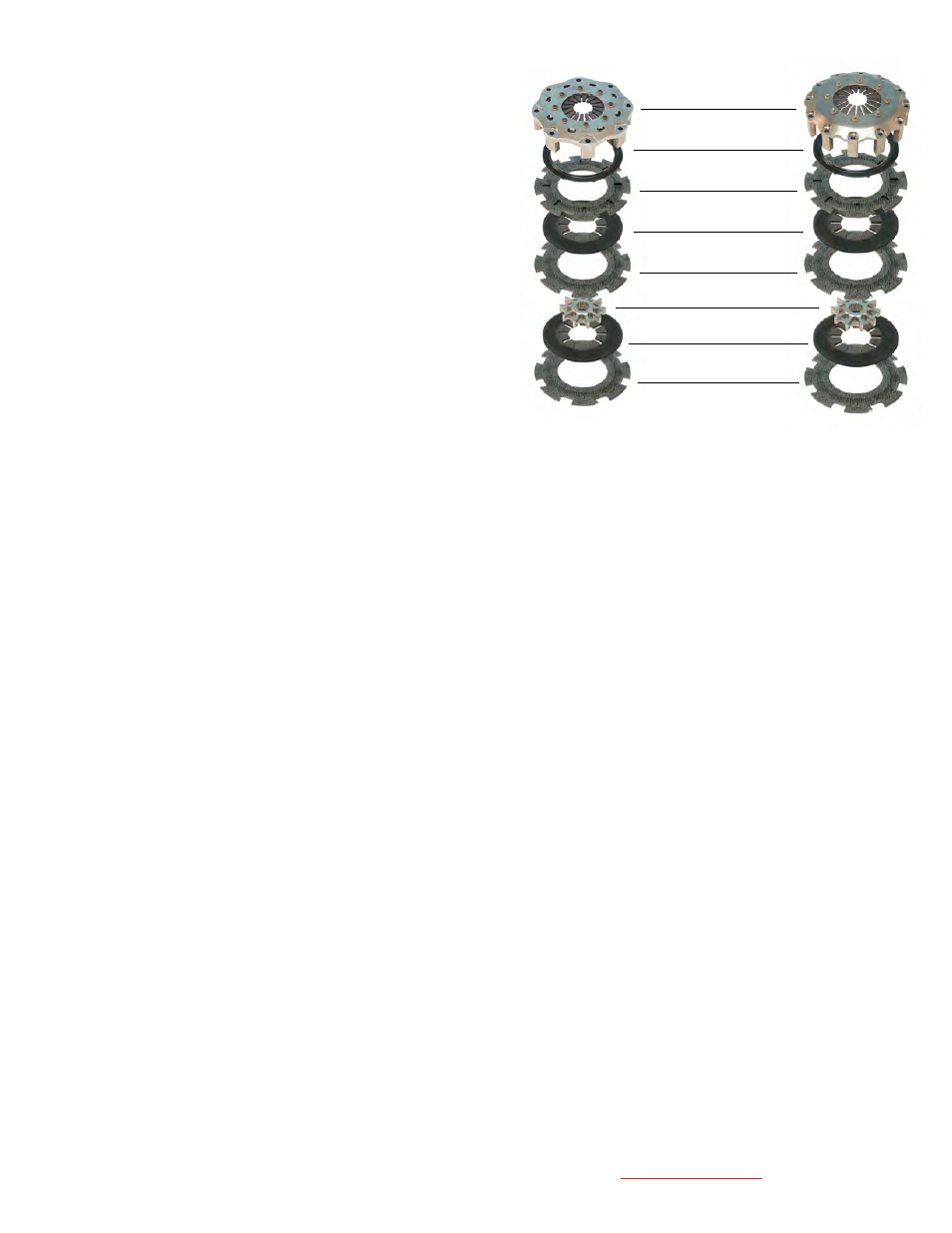

Cover Assembly

Pressure Ring/Plate

First Floater [^]

First Drive Plate [X]

Second Floater [^^]

Drive Hub

Second Drive Plate [XX]

Third Floater [^^^]