SANDPIPER RuppTech Stroke Counter/Batch Control User Manual

Stroke counter/batch control, Service and operating manual

Batch Control/Stroke Counter

Page 1

Batch-sc-rev0611

520-180-000 3/02

Batch Control / Stroke Counter

Page 1

A General Overview of this Control System

This control functions in two modes of operation:

• stroke counter mode

• batch controller mode

The two modes can be operated together or alone.

The control receives a signal from the diaphragm pump for each

pump stroke. It accomplishes this through a

RuppTech® Pulse Output

Interface mounted on the pump.

RuppTech

®

Pulse Output Interface - (available ONLY

from Warren Rupp, Inc.)

The Pulse Output Interface mounts on the pump and provides

electrical signals to operate the Control. This creates an electrical

interface between the control and the air-powered pump.

Each pump stroke generates a signal through a proximity switch (PNP)

on either end of the air valve. As the air valve reciprocates back and forth

during pump operation, targets on either end of the sleeve and spool

set trigger their respective proximity switches. Each trigger signals the

control to register one count on the stroke counter / batch control unit.

This method provides a positive signal for every pump stroke.

The Pulse Output Interface are designed for easy field installation. The

interfaces are also available factory-installed on new pumps. Pulse Output

Interfaces can be purchased separately from the control unit for those

applications where a process controller is already present in a system.

This provides a direct interface with the pump and the customer’s

system.

Stroke Counter Mode

In this mode, the control keeps a running tally of the total number of

strokes of the pump. The control saves this total until the accumulated

count is reset from the control’s keyboard, or the counter exceeds the

10-digit capacity of the display. The count can be pump strokes (one for

every stroke), or a measure of volume (i.e. gallons, liters, pounds) to

indicate total volume pumped. The stroke count could also be used

to indicate how long the pump has run. This is helpful for preventative

maintenance schedules, or to account for the volumes of fluid being

transported or consumed. The stroke counter function is cumulative,

even if the pump is turned off and on by some means other than the

control. Any time the pump is running and the control is powered, it will

store the total count for future reference.

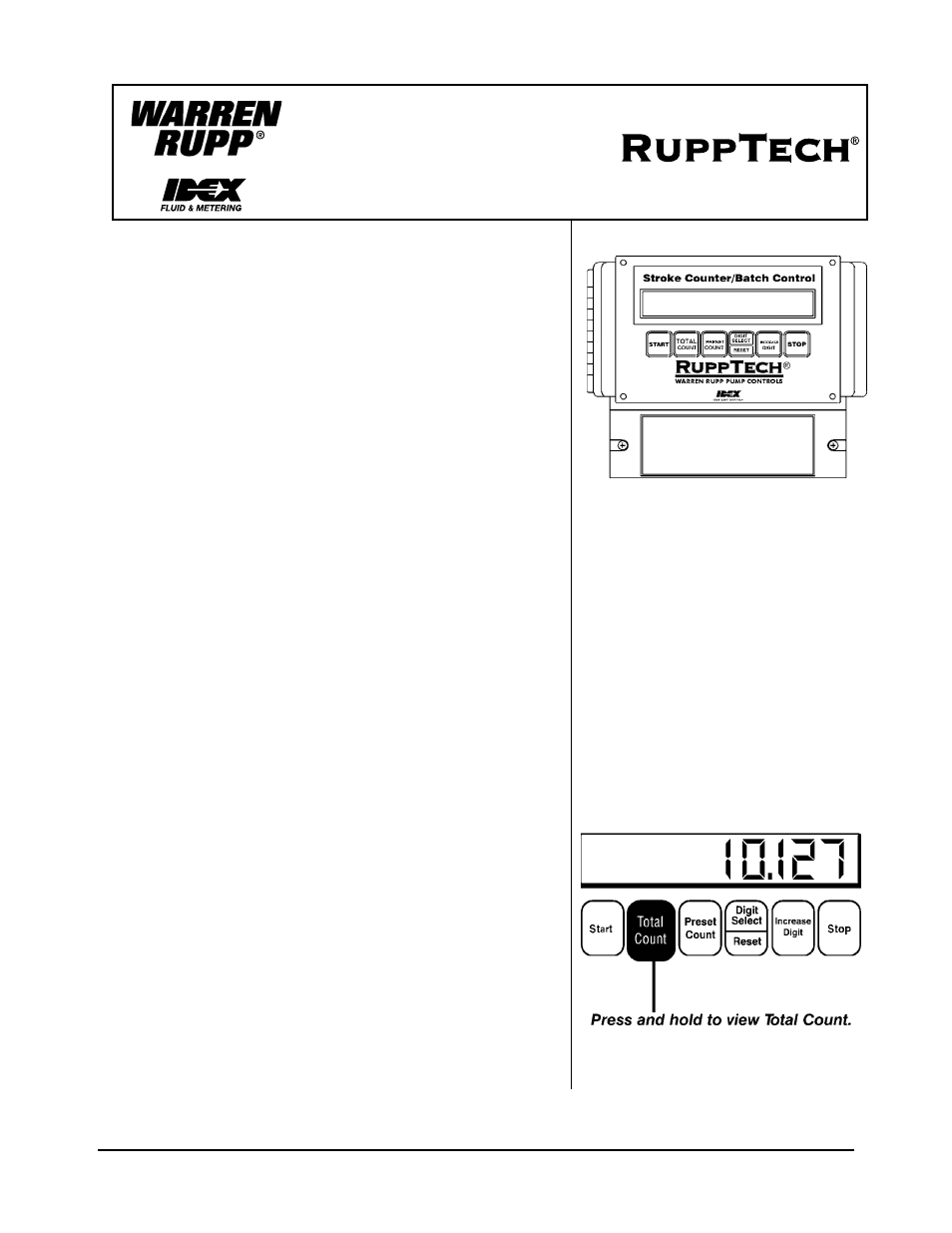

To view the totalized count, push and hold the Total Count button on

the control keyboard. (To extend the life of the LED display, the count

does not display continuously.) Refer to the Programming Instructions

in this manual to set the scale per stroke or reset the count.

Warren Rupp, Inc. A Unit of IDEX Corporation • P.O. Box 1568 • Mansfield, OH 44901-1568 USA • 419 524 8388 Fax 419 522 7867 www.warrenrupp.com

SERVICE AND OPERATING MANUAL

Stroke Counter/Batch Control

249-006-000 • 100-120/240VAC • 50/60

hertz

NEMA 12 Enclosure

Height 6.1” (15.5cm)

Width 6.54” (16.6cm)

Depth 3.46” (8.8cm)

10-digit LED display

4 push buttons for setup

10A relay output for solenoid valve

2 proximity sensor inputs

2 remote on/off switch inputs

Warren Rupp, Inc. A Unit of IDEX Corporation • P.O. Box 1568 • Mansfield, OH 44901-1568 USA • 419 524 8388 Fax 419 522 7867 www.warrenrupp.com