Load, Outputs, 5a 250v – SANDPIPER ELECTRONIC LEAK DETECTOR 032-037-000, 032-043-000 User Manual

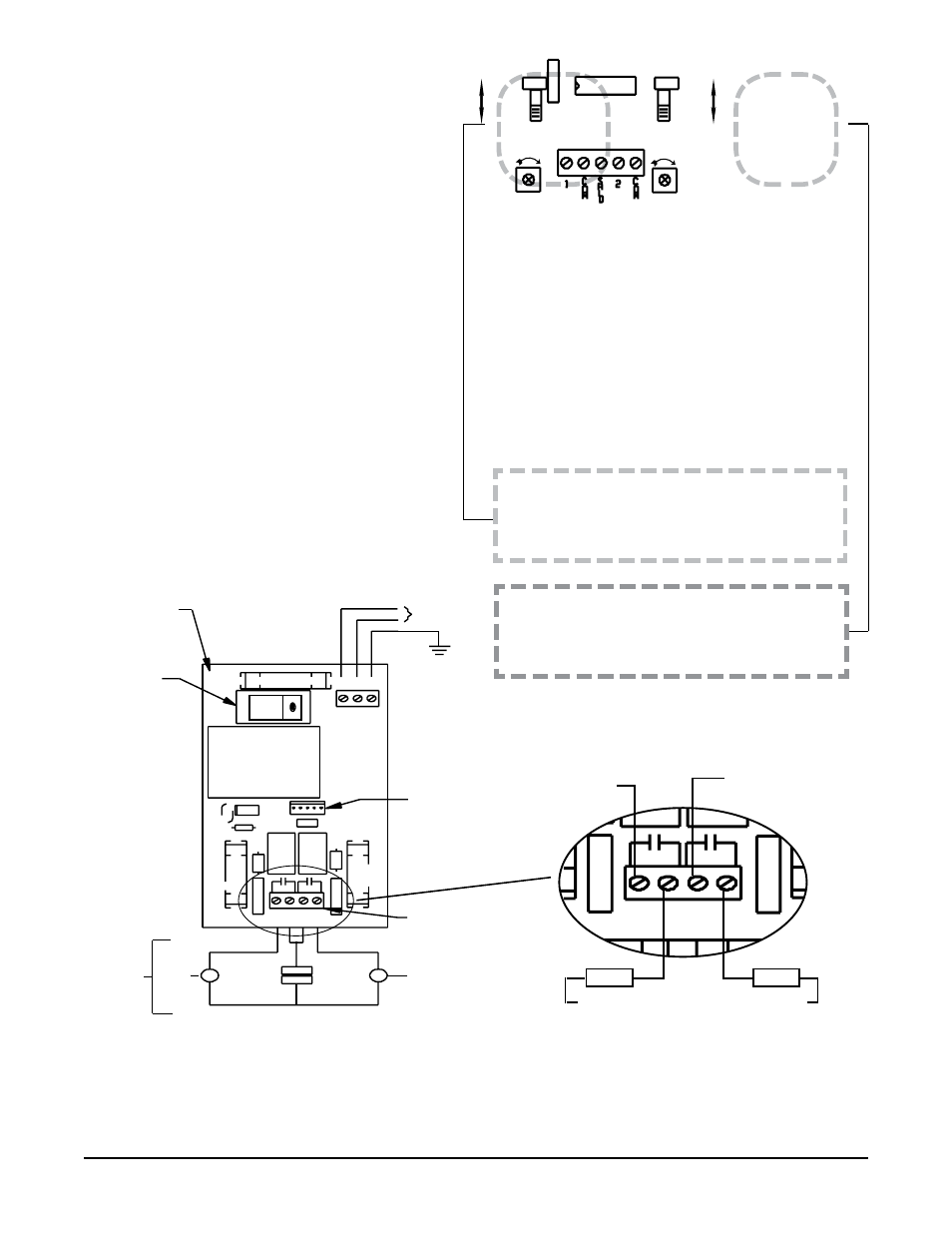

Page 5: C6 c5, C7 1, Cr1 cr2

eldvacsm-rev0513

Electronic Leak Detector-VAC Page 5

UP

DOWN

UP

DOWN

ALMLO

ALMHI

ALMLO

ALMHI

SW1

TS1

R5

INC-

SENS

CW

INC-

SENS

CW

R6

SW2

CH1

CH2

C3

Conductivity:

The leak detector probes work under the principle

of conductance. Not all pumped liquid is conductive,

such as when using this device with a spill contain-

ment type SANDPIPER pump. Ideally, if the pumped

product is conductive, then the driver fluid should be

non-conductive. The driver fluid must be compatible

with the driver diaphragm and be compatible with the

pumped product. If the pumping diaphragm fails, the

pumped product will conduct (complete the circuit)

and signal the box and the warning light will come

on. If the reverse is required, such as pumping non-

conductive fluid, the driver fluid should be conductive.

If this is the case, move the two switches located in

the cover marked SW1 and SW2, to the opposite

locations. (See the close-up Figure D).

Sensitivity of this detector can be adjusted by the

adjusting knobs R5 and R6. (See Figure D.) These

adjusting knobs work independently for each side

(chamber). They can be moved with a small screw-

driver. These sensitivity knobs are also important in

setting to detect conductance fluid at the sensitivity

most required. The sensitivity range of the detector

is adjustable from 500 OHM (2,000 Micro MHO) to

100,000 OHM (10 Micro MHO).

When sensing low conductivity, turning the screws

clockwise increases probe sensitivity.

FIGURE D

(See ENCLOSURE LID, Figure C)

Page 4

FIGURE E

Conductive/Non-Conductive Switch Information

Note: Pumps containing driver fluid should be filled

with conductive or non-conductive fluid, depending on

the fluid pumped. The driver fluid should be opposite

of the pumped product in order to determine diaphragm

failure and light warning LED signal(s). This is adjusted

inside the box in the following manner:

SW1 DOWN (LED 1) = LED on w/presence of

conductive fluid and off w/absence of conductive fluid.

SW1 UP (LED 1) =LED on w/absence of conductive fluid

and off w/absence of conductive fluid.

— OR —

SW2 DOWN (LED 2) = LED on w/presence of

conductive fluid and off w/absence of conductive fluid.

SW2 UP (LED 2) = LED on w/absence of conductive fluid

and off w/absence of conductive fluid.

LOAD

LOAD

PICTOGRAM

FOR FUSE FU1

POWER PROTECTION

DRY CONTACT

ALARM OUTPUTS

TO PROBE

PICKUP

BOARD

AC OR DC

220V/5A

MAX

OUTPUTS

C6

C5

1

2

TS2

C7

1

TS1

FU1

.5A

250V

P1

CR1

CR2

FU2

1A

250V

FU3

1A

250V

POWER

RTN

OPTIONAL

EXTERNAL

OUTPUT

JUNCTION FOR

SOLENOID

VALVES OR

SIGNALS

OUTPUTS

C6

C5

1

2

TS2

LINE

VOLTAGE

SELECT

INSERT SCREW DRIVER

IN SLOT AND SLIDE TO

CHANGE VOLTAGE

CAUTION: REMOVE

POWER FIRST

115/230VAC

50/60 Hz

L1 L2 G

115V

When sensing low conductivity, turning the

screws clockwise increases probe sensitivity.

100-120VAC

(HOT)

100-120VAC

(HOT)

AC Neutral

Load will be energized

when LED 1 is illmunated

This load is fused by FU2

AC Neutral

Load will be energized

when LED 2 is illmunated

This load is fused by FU3

LOAD

LOAD

PICTOGRAM

FOR FUSE FU1

POWER PROTECTION

DRY CONTACT

ALARM OUTPUTS

TO PROBE

PICKUP

BOARD

AC OR DC

220V/5A

MAX

OUTPUTS

C6

C5

1

2

TS2

C7

1

TS1

FU1

.5A

250V

P1

CR1

CR2

FU2

1A

250V

FU3

1A

250V

POWER

RTN

OPTIONAL

EXTERNAL

OUTPUT

JUNCTION FOR

SOLENOID

VALVES OR

SIGNALS

OUTPUTS

C6

C5

1

2

TS2

LINE

VOLTAGE

SELECT

INSERT SCREW DRIVER

IN SLOT AND SLIDE TO

CHANGE VOLTAGE

CAUTION: REMOVE

POWER FIRST

115/230VAC

50/60 Hz

L1 L2 G

115V

LOAD

LOAD