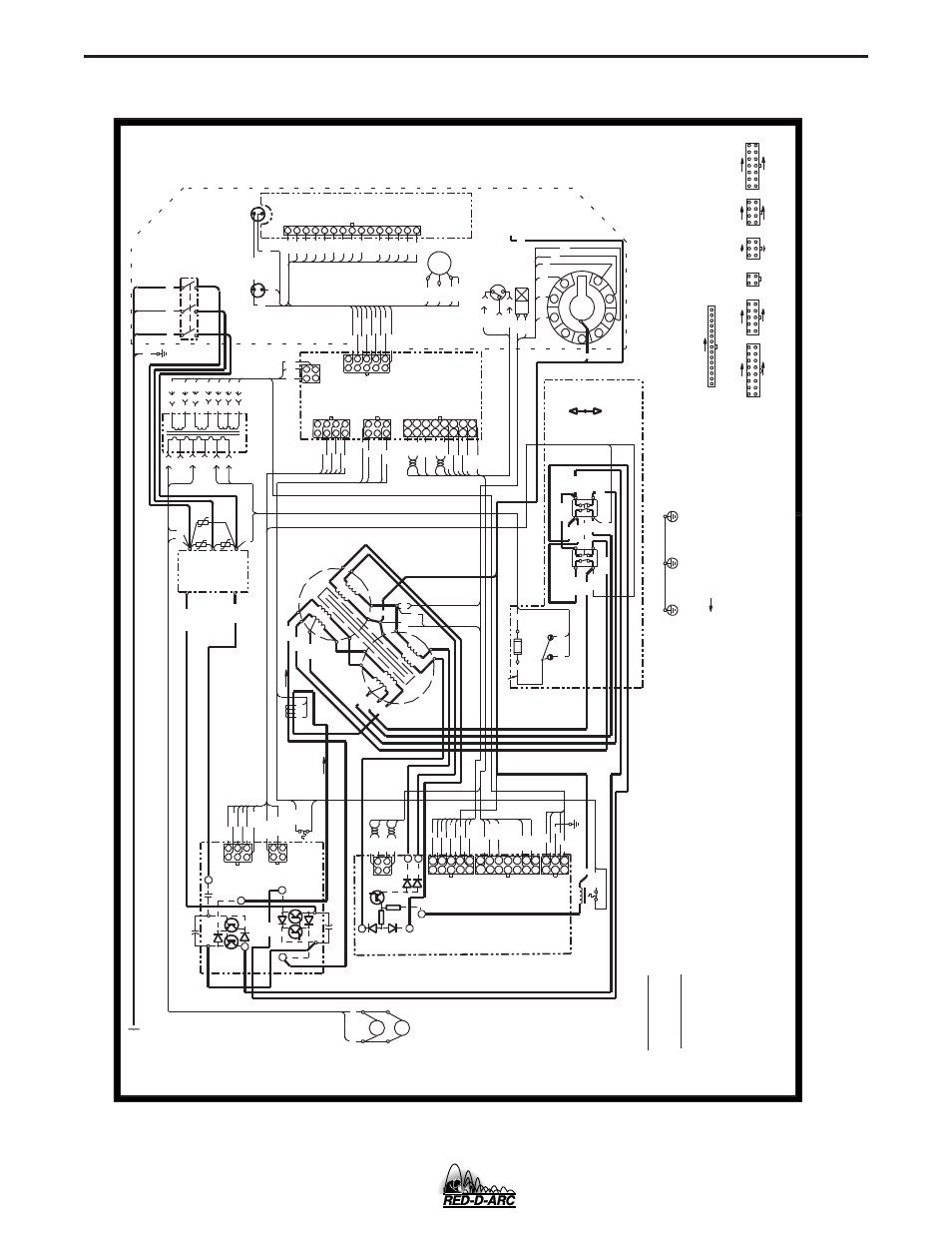

Diagrams, Viper – Lincoln Electric IM639 RED-D-ARC VIPER User Manual

Page 31

F-2

DIAGRAMS

F-2

VIPER

8

2

5

503

213

506

214

502

218

H1

215

210

Y

16

8

15

7

302

14

6

W

9

312

H1

H3

231

202

X4

201

201A

460VAC

231A

507

I

506

505

B

U

R

S1

V

W

POWER

W

54

53

8

12V

R

N

56

R

N

51

2

24V

J5,J10,J22

J4,J30

J40

11

12

215

210

214

219

213

218

N.C. PLACE "A" LEAD ON APPROPRIATE CONNECTION FOR INPUT VOLTAGE.

4

277A

306

COMPONENTS OR CIRCUITRY HAVING A COMMON CODE NUMBER.

THE INTERCHANGEABILITY OF A COMPLETE BOARD, THIS DIAGRAM MAY NOT SHOW THE EXACT

212

248

N.B. SINCE COMPONENTS OR CIRCUITRY OF A PRINTED CIRCUIT BOARD MAY CHANGE WITHOUT AFFECTING

217

216

ELECTRICAL SYMBOLS PER E1537

12

3

4

13

4

6

E

1

8

7

14

N

H2

3

209

J10

501

A

306

X4

303

302

CONTROL

309

N.C.

360

1200/450

5

4

6

4

440- 460V

5

OUTPUT

+

-

J31

6

R

W

501

S

BK-OUT

S

BK-IN

219

R = RED

(VIEWED FROM COMPONENT SIDE OF BOARD)

W = WHITE

CONNECTOR CAVITY NUMBERING SEQUENCE

G = GREEN

B = BLACK

COLOR CODE:

DISPLAY

WORK

364

369

2

2W

10K

4

CW (MAX)

277

276

R1

R

W

Y

366

361

J20

J32

1

2

U = BLUE

N = BROWN Y = YELLOW

+

-

ELEC

XFER

XFER

IN_SENSE

ELEC

REAR OF MACHINE

J11

502

11

4

5

5

6

7

1

2

3

1

2

3

9 AIR SOL

TSTAT

10 ELEC SOL

P_XFMR

++VOLT

RELAY

4

10

3

2

1

12

13

2,6 PSI SWITCH

5

11 TRIGGER

CT

12 GND

3 IGBT

J3

B

BASE

PROTECTIVE BONDING CIRCUIT

CASE FRONT

J1

BK-OUT

64

61

62

18V

LOW_PSI LED

POT WIPER

RESET

GND

THERMAL LED

RESET LED

PSI SET

1

1

14

217

13

212

H6

2

H5

1

3

H4

275

H3

507

J21

T2

AUXILIARY

TRANSFORMER

U

64

62

W

61

U

TP3

9

H1

TP2

TP1

H1

B

A

C

D1

INPUT

BRIDGE

209

4

5

1

FRONT OF MACHINE

365

J4

N.A.

PER

INPUT

221

223

221

275

276

277

1

1

J2,J21,

J31

2

241A

241A

4

+15V

READY LED

277B

18V

18V

J2

7,8 ELEC SHUNT (TWIST PR)

N

4,5 XFER SHUNT (TWIST PR)

LEFT SIDE OF MACHINE

X40

0.6A

RELAY

P_XFMR

++VOLT

365

RESET

15

SOLENOID

216

223

S3

PSI_SET

277A

4

303

312

1

7

3

2

3

2

3

E

MOTORS

W

401

X2

FAN

OUTPUT

PC BOARD

FAN

361

364

360

404

369

366

2

401

4

B21

L1

CHOKE

J40

J3

WIRING DIAGRAM VIPER CODE 10635

SLOW BLOW

E

R

8

1

7

2

6

5

4

550- 575V

H6

H5

W

3

4

9

10

1

309

8

344

NOTES:

THREE PHASE INPUT: CONNECT GREEN LEAD TO GROUND PER NATIONAL ELECTRIC CODE.

N.A. 1. FOR MACHINES SUPPLIED WITH INPUT CABLE

CONNECT BLACK, RED & WHITE LEADS TO SUPPLY CIRCUIT.

2. FOR MACHINES NOT SUPPLIED WITH INPUT CABLE

THREE PHASE INPUT: GROUND MACHINE PER NATIONAL AND LOCAL ELECTRICAL CODES.

CONNECT TERMINALS U, V & W TO SUPPLY CIRCUIT.

N.D. CONNECTION SHOWN IS FOR 575V OPERATION.

4

8

1

5

15

5

10

1

6

8

16

9

5

10

BK-IN

S

10-30-98

RIGHT SIDE OF MACHINE

440-

207A

2

Y

C1

S

S

FR-OUT

1200/450

S

J1,J20, J33

S

344

310

N

N

205

9

1,4=24V

13 IGBT

14

13

12

11

10

14 GND

1,2 TRIGGER

4 ELECTRODE

5,6 AIR SOL

J32

12V

3 NOZZLE

X20

X40

7,8 ELEC SOL

10 WORK

2 ELEC SOL

8 AIR SOL

3 TRIGGER

9

3

248A

241

53

56

201

G

201A

54

51

231

8

7

1

6

FAN

404

2

4

3

503

3

2

5

1

4

204

J30

241

xxxxxxx

205

204

D

+

A

8

J5

575VAC

241

-

F

550-

S4 PRIMARY

RECONNECT

J33

310

208

6

18V

6

G

S2

xxxxxxx

FR-OUT

FR-IN

S

505

CONTROL

S5

X1

PRESSURE

AIR

C2

R

A

2

5

206

202

6

POWER

T3

I

R

Y

Y

208

238

S

1

248

T1

MAIN

XFMR

X2

X20

X30

X3

W

X10

TRANSFORMER

CURRENT

6

2

7

3

207A

L10972

7

10

9

4

8

7

6

J22

5

4

3

POT

1

6

2

4

7

3

8

W

4

9

FR-IN

A

231A

238

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diag

ram for a particular code is pasted inside

the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacement. G

ive the equipment code number..