Operation, Hidden middle control panel – process set up panel – Lincoln Electric IM980 RED-D-ARC EX350ie (CE) User Manual

Page 15

B-2

OPERATION

B-2

5. THERMAL

• This status light indicates when the power source

has been driven into thermal overload. If the out-

put terminals were "ON", the "ON" light will blink

indicating that the output will be turned back on

once the unit cools down to an acceptable temper-

ature level. If the unit was operating in the

"REMOTE" mode, the trigger will need to be

opened before or after the thermal has cleared and

closed after the machine has cooled down to an

acceptable temperature to establish output.

6. CONTROL-REMOTE , LOCAL

• Two status lights indicate the location of output

control as pre-determined by the power sources

auto-configure system.

• The LOCAL display will be lit when control is at the

power source.

• The REMOTE display will be lit when a remote

pot/control is detected.

These Output Control configurations can be over-

ridden (switched) with the CONTROL push button.

When changed, the unit will power up in the config-

uration it was in when it was last powered down.

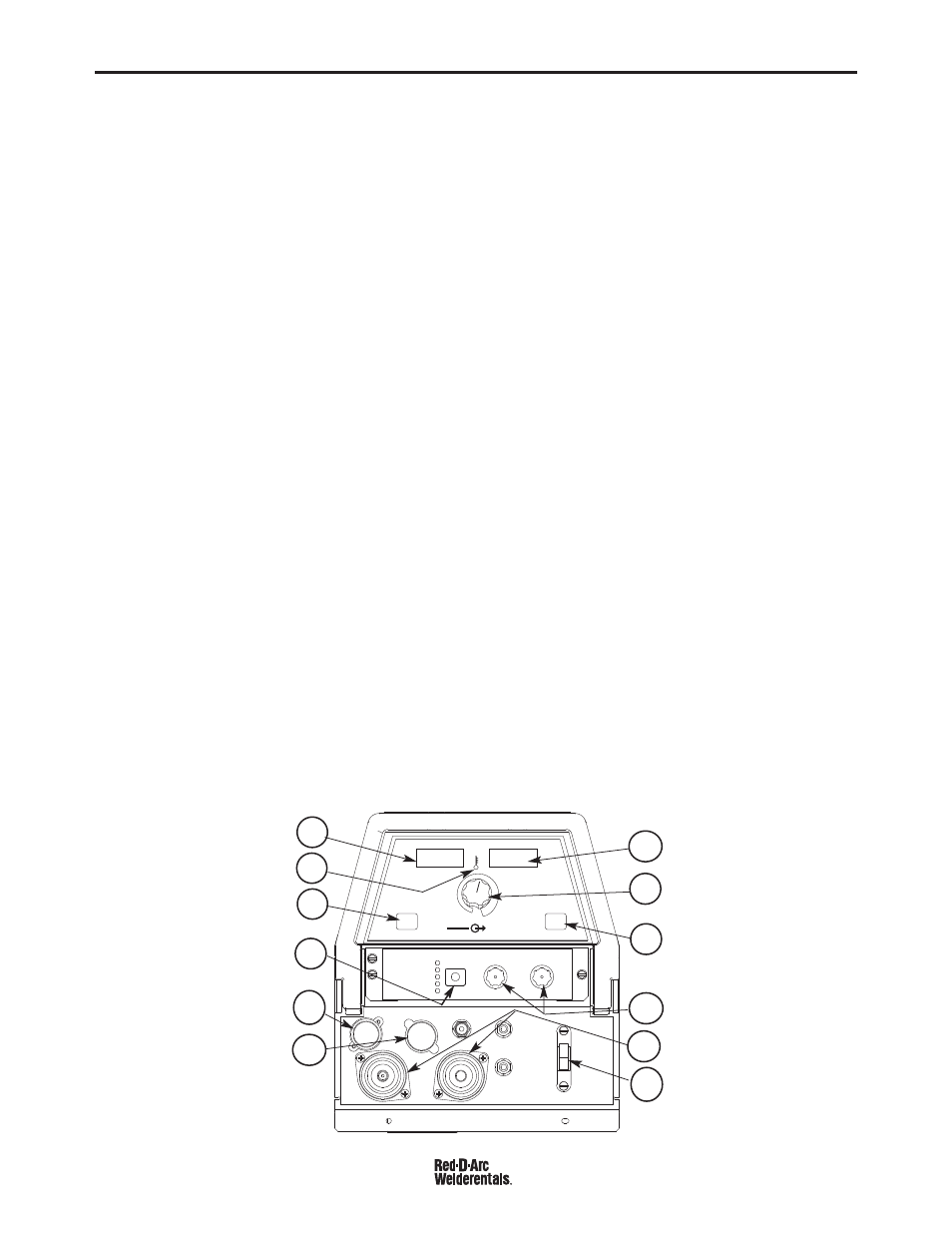

Hidden Middle Control Panel – Process

Set Up Panel

The middle control panel is removable to allow for

upgrades (see Field Installed Options/Accessories).

Additionally, this panel is hidden by an access door to

reduce appeared complexity and provide protection to

the controls.

7. WELD MODE SELECT

The Mode Control button selects the following weld-

ing modes desired.

CC-STICK SOFT: The Stick Soft process features

continuous control ranging from 5 to 425 amps. This

mode was intended for most SMAW applications, and

Arc Gouging.

• Arc Gouging: Setting the output of the Stick Soft

mode to 425 amps and/or setting the arc control to

9.5 or above will enable the arc-gouging mode.

The actual output current will depend on the size of

carbon used. The recommended maximum size

carbon is 5/16"(7.9mm).

• The Hot Start control regulates the starting current

at arc initiation. Hot Start can be adjusted from min-

imum (0), with no additional current added at arc

start, to maximum (10), with double the preset cur-

rent or 425 amps (max of machine) added for the

first second after arc initiation.

• The Arc Control regulates the Arc Force to adjust

the short circuit current. The minimum setting (-10)

will produce a "soft" arc and will produce minimal

spatter. The maximum setting (+10) will produce a

"crisp" arc and will minimize electrode sticking.

CC-STICK CRISP: The Stick Crisp mode features

continuous control from 5 to 425 amps. This mode

was intended primarily for pipe welding applications.

• The Hot Start control regulates the starting current

at arc initiation. Hot Start can adjust starting current

up or down by 25% of the preset value. The recom-

mended setting for Hot Start is 5 where the initial

current is equal to the preset current.

• Arc Gouging: Setting the output of the stick crisp

mode to 425 amps and/or setting the arc control to

9.5 or above will enable the arc-gouging mode. The

actual output current will depend on the size of car-

bon used. The recommended maximum size car-

bon is 5/16”(7.9mm)

EX350ie (CE) (RED-D-ARC)

REMOTE

REMOTE

ON

ON

REMOTE

REMOTE

LOCAL

LOCAL

WELD TERMINALS

WELD TERMINALS

OUTPUT

OUTPUT

CONTROL

CONTROL

SELECT

SELECT

SELECT

SELECT

MPS

MPS

A

OLTS

OLTS

V

1

6

5

2

3

4

8

7

11

10

12

9

FIGURE 1