Operation, Welding controls – Lincoln Electric IM813 RANGER 305 D (CE) User Manual

Page 20

B-2

OPERATION

B-2

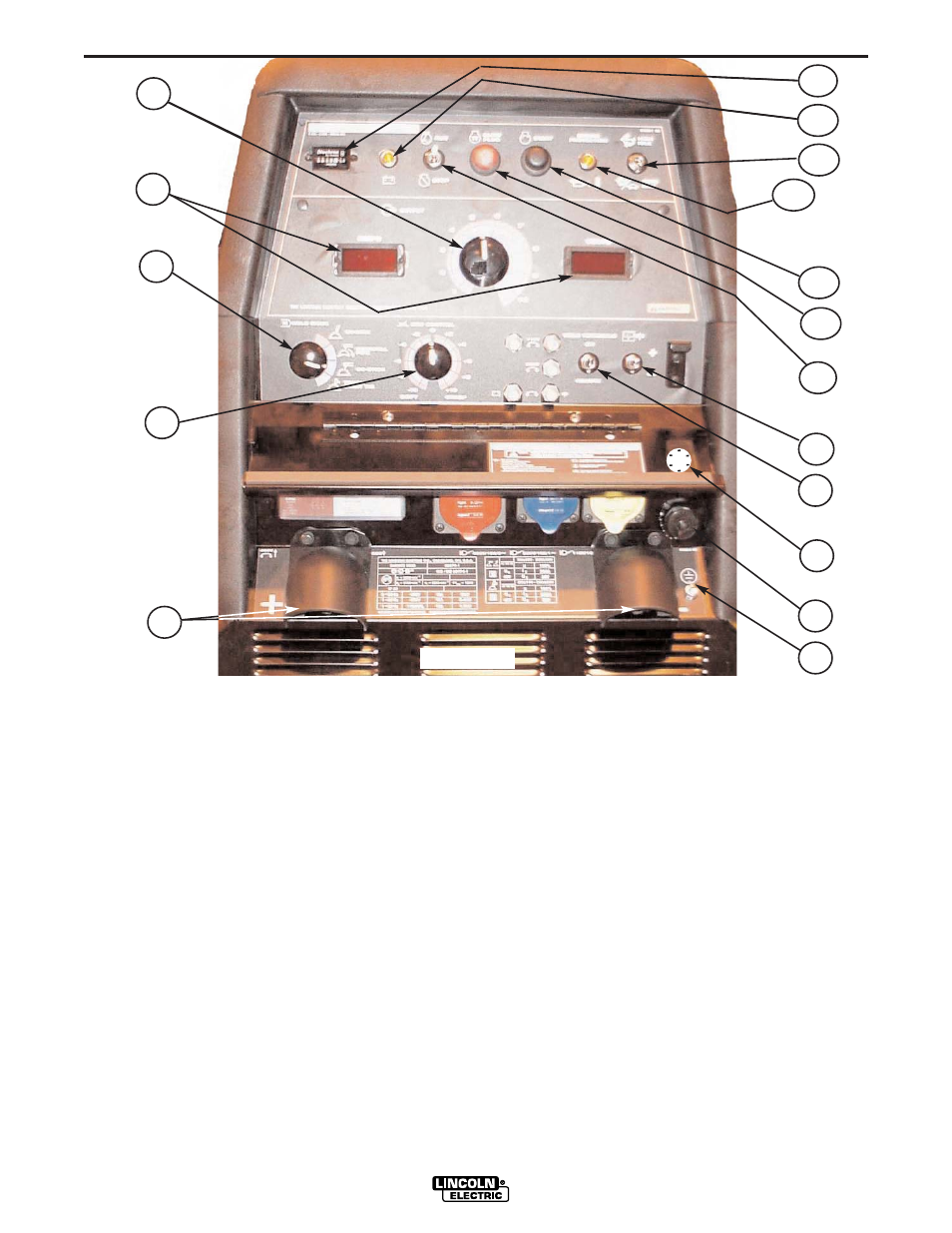

WELDING CONTROLS

(Figure B.1)

1. OUTPUT CONTROL:

The OUTPUT dial is

used to preset the output voltage or current as dis-

played on the digital meters for the four welding

modes. When in the CC-STICK, DOWNHILL PIPE

or CV-WIRE modes and when a remote control is

connected to the 6-Pin or 14-Pin Connector, the

auto-sensing circuit automatically switches the

OUTPUT CONTROL from control at the welder to

the remote control.

In the CV-WIRE mode, if the wire feeder has volt-

age control capability, when the control cable is

connected to the 14-Pin Connector, the auto-sens-

ing circuit automatically makes OUTPUT CON-

TROL inactive and the wire feeder voltage control

active.

When in the TOUCH START TIG mode and when

a Amptrol is connected to the 6-Pin Connector, the

OUTPUT control is used to set the maximum cur-

rent range of the CURRENT CONTROL of the

Amptrol.

2. DIGITAL OUTPUT METERS

The digital meters allow the output voltage (CV-

WIRE mode) or current (CC-STICK, PIPE and TIG

modes) to be set prior to welding using the OUT-

PUT control dial. During welding, the meter display

the actual output voltage (VOLTS) and current

(AMPS). A memory feature holds the display of

both meters on for seven seconds after welding is

stopped. This allows the operator to read the actu-

al current and voltage just prior to when welding

was ceased.

While the display is being held the left-most deci-

mal point in each display will be flashing. The

accuracy of the meters is +/- 3%.

3. WELD MODE SELECTOR SWITCH:

(Provides four selectable welding modes)

CV-WIRE

DOWNHILL PIPE

CC-STICK

TOUCH START TIG

RANGER 305D (CE)

1

10

7

4

9

5

8

11

12

13

6

15

14

17

16

2

3

FIGURE B.1