Installation, Warning, Caution – Lincoln Electric IM813 RANGER 305 D (CE) User Manual

Page 17

A-5

INSTALLATION

RANGER 305D (CE)

A-5

WELDING TERMINALS

The machine is equipped with a toggle switch for

selecting "hot" welding terminal when in the "WELD

TERMINALS ON" position or "cold" welding terminal

when in the "REMOTE" position.

WELDING OUTPUT CABLES

With the engine off connect the electrode and work

cables to the output studs. The welding process dic-

tates the polarity of the electrode cable. These con-

nections should be checked periodically and tightened

with a 19mm wrench.

Table A.1 lists recommended cable sizes and lengths

for rated current and duty cycle. Length refers to the

distance from the welder to the work and back to the

welder. Cable diameters are increased for long cable

lengths to reduce voltage drops.

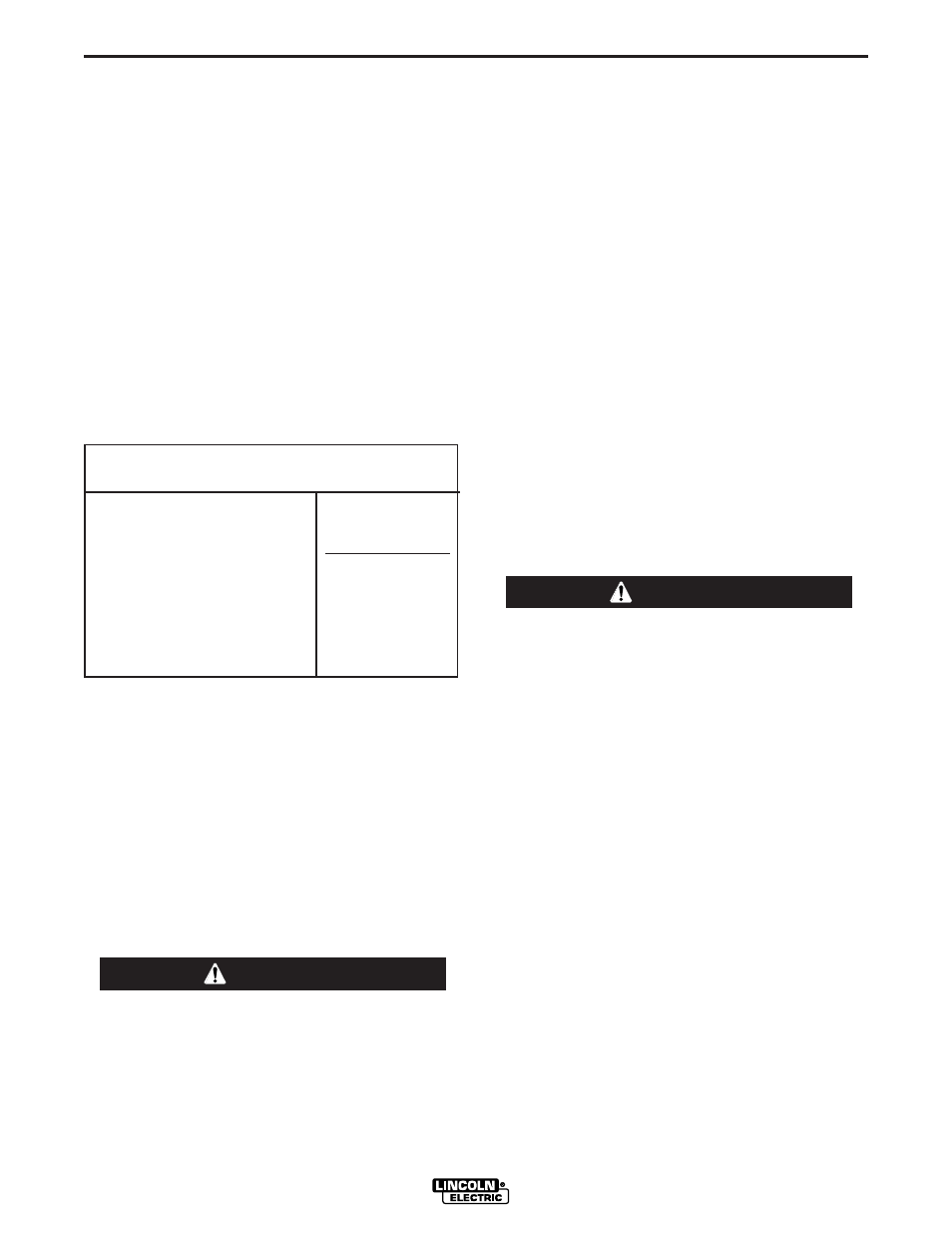

TABLE A-1

CABLE INSTALLATION

Install the welding cables to your machine as follows:

1. The diesel engine must be OFF to install welding

cables.

2. Remove the flanged nuts from the output terminals.

3. Connect the electrode holder and work cables to

the weld output terminals. The terminals are identi-

fied on the case front.

4. Tighten the flanged nuts securely.

5. Be certain that the metal piece you are welding (the

“work”) is properly connected to the work clamp and

cable.

6. Check and tighten the connections periodically.

• Loose connections will cause the output termi-

nals to overheat. The terminals may eventually

melt.

• Do not cross the welding cables at the output

terminal connection. Keep the cables isolated

and separate from one another.

------------------------------------------------------------------------

AUXILIARY POWER

The auxiliary power capacity is 8500 watts Peak,

8,000 Watts Continuous of 50 Hz, three phase power.

The auxiliary power capacity rating in watts is equiva-

lent to volt-amperes at unity power factor. The max

permissible current of the 400 VAC output is 20 amps.

Output voltage is within ± 10% at all loads up to the

rated capacity.

STANDBY POWER CONNECTIONS

The machine is suitable for temporary, standby or

emergency power using the engine manufacturer’s

recommended maintenance schedule.

The machine can be permanently installed as a stand-

by power unit for 400 VAC, three phase, 20 amp ser-

vice.

Connections must be made by a licensed electrician

who can determine how the power can be adapted to

the particular installation and comply with all applica-

ble electrical codes.

• Take necessary steps to assure load is limited to the

capacity of the RANGER 305D (CE).

• Only a licensed, certified, trained electrician

should install the machine to a premises or resi-

dential electrical system. Be certain that:

• The installation complies with the National

Electrical Code and all other applicable electrical

codes.

• The premises is isolated and no feedback into

the utility system can occur. Certain laws require

the premises to be isolated before the generator

is linked to the premises. Check your local

requirements.

-----------------------------------------------------------------------

CONNECTION OF LINCOLN ELECTRIC

WIRE FEEDERS

Connection of LN-15 to the RANGER 305D (CE)

These connections instructions apply to both the LN-

15 Across-The-Arc and Control Cable models. The

LN-15 has an internal contactor and the electrode is

not energized until the gun trigger is closed. When the

gun trigger is closed the wire will begin to feed and the

welding process is started.

• Shut the welder off.

• For electrode Positive, connect the electrode cable to

the "+" terminal of the welder and work cable to the "-

" terminal of the welder. For electrode Negative, con-

nect the electrode cable "-" terminal of the welder

and work cable to the "+" terminal of the welder.

WARNING

TOTAL COMBINED LENGTH OF

ELECTRODE AND WORK CABLES

Cable Length

0-30meters (0-100Ft.)

30-46m meters (100-150 Ft.)

46-61 meters (150-200 Ft.)

Cable Size for

305 Amps

100% Duty Cycle

1 / 0 AWG

2 / 0 AWG

3 / 0 AWG

CAUTION