Operation, Warning – Lincoln Electric IM944 POWERTORCH PLASMA 20 User Manual

Page 13

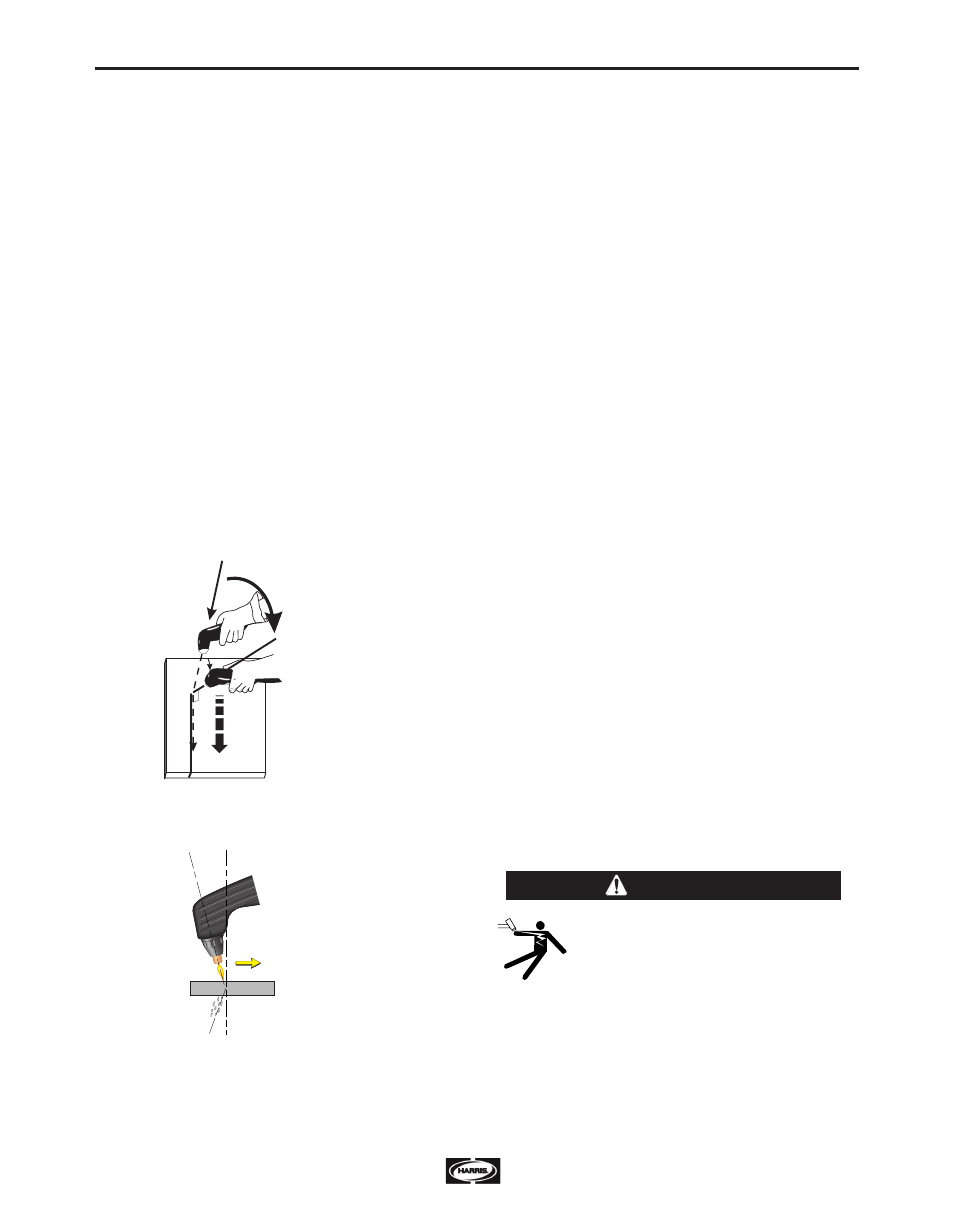

Direction of Travel

5

° - 15°

10

° - 20° Arc Lag

Leading Angle

• Use a 5° - 15° leading angle in the direction of the cut.

• Finish the cut to be made and release the trigger.

NOTE: For better torch control, it is acceptable to let

the nozzle drag along the work piece surface. This

will shorten nozzle life. Also, it is acceptable to place

a non-conductive torch guide on the work piece in

order to achieve a cleaner cut

• When the trigger is released, the arc will stop.

- The gas will continue to flow for 20 seconds of

postflow. If the trigger is activated within this time

period, the pilot arc will restart after the 3 second

delay.

• If the dross is difficult to remove, reduce the cutting

speed. High speed dross is more difficult to remove

than low speed dross.

• The right side of the cut is more square than the left

as viewed along the direction of travel.

• Clean spatter and scale from the nozzle frequently.

Parts in place:

• Check the assembly of the torch consumables. If

they are not properly in place, the machine will not

start. Make sure that the shield cup is hand

tight. Do not use pliers or over tighten.

• Check the conditions of the inside of the nozzle. If

debris has collected, rub the electrode on the inside

bottom of the nozzle to remove any oxide layer that

may have built up. Refer to the “Routine

Maintenance Section".

• Check the condition of the electrode. If the end has

a crater-like appearance, replace it along with the

nozzle. The maximum wear depth of the electrode

is approximately .062”. A green and erratic arc will

indicate definite electrode failure and the electrode

should be replaced immediately.

• Replace the nozzle when the orifice exit is eroded

away or oval shaped.

• If the machine does not reset or continues to trip,

consult the Troubleshooting Section.

• Use the proper cutting procedures referred to in

Procedure Recommendations.

ELECTRIC SHOCK CAN KILL.

Disconnect input power by removing

the plug from the receptacle before

assembling or disassembling torch

parts, or torch and lead assemblies.

------------------------------------------------------------------------

WARNING

B-4

OPERATION

B-4

• When ready to cut, place the torch near the work,

make certain all safety precautions have been taken

and pull the trigger.

- The air will flow for a preflow time of 3 seconds

and the pilot arc will start.

- The pilot arc will run for 3.0 seconds and shut off

unless the arc is brought in contact with the work

and the arc is transferred. Avoid excessive pilot

arc time by transferring the arc to the workpiece

quickly.

- When the arc is brought within 1/8” - 1/4" from

the work piece: the arc will transfer, the current

will ramp to the setting on the control panel, and

the cut can last indefinitely (or until the duty cycle

of the unit is exceeded).

• Pierce the work piece by slowly lowering the torch

onto the metal at a 30

0

angle away from the opera-

tor. This will blow the dross away from the torch noz-

zle. Slowly rotate the torch to vertical position as the

arc becomes deeper.

NOTE: Graphics shown are for understanding torch

angles for best results – the distances from the work

piece are exaggerated. In actual operation, the noz-

zle should be held just above the work piece surface.

• Keep moving while cutting. Cut at a steady speed

without pausing. Maintain the cutting speed so that

the arc lag is 10° to 20° behind the travel direction.

POWERTORCH™ PLASMA 20

30

30

00

VER

VERTICAL ANGLE

TICAL ANGLE

FOR CUTTING

FOR CUTTING

CUT

90

0

TORCH AT 30

0

ANGLE

TO PIERCE

ROTATE TO

90

0

ANGLE TO CUT