Operation, Safety precautions description, Warning – Lincoln Electric IM944 POWERTORCH PLASMA 20 User Manual

Page 10

B-1

OPERATION

POWERTORCH™ PLASMA 20

B-1

SAFETY PRECAUTIONS

DESCRIPTION

The POWERTORCH™ PLASMA 20 is a constant cur-

rent, continuous control plasma cutter power source.

The POWERTORCH™ PLASMA 20 comes standard

with an air regulator and pressure gauge. The unit is

powered from a 115Vac, 20 amp input circuit with a

40% duty cycle rating on a 10 minute basis, with 20

amp output. The unit includes a hand-held torch with

consumables and a work cable with clamp.

The POWERTORCH™ PLASMA 20 utilizes a 3 sec-

ond delay after pressing the trigger before arc initia-

tion to ensure that the operator is ready. The unit will

not function if consumables are not installed correctly

or missing, protecting the user. The unit uses pneu-

matic-action touch starting for arc initiation and does

not use high-frequency.

Plasma is a gas that is heated to an extremely high

temperature and ionized so that is becomes a conduc-

tor of electricity.

This cutting procedure utilizes the plasma to transfer

the electric arc to the metal workpiece. The arc melts

a small amount of the work piece and the compressed

air blows away the molten metal there by producing

the cutting action.

The torch uses compressed air from a single source,

for both the plasma, cooling and protective gas.

The start of the cycle is determined by an arc, called

the pilot arc, which is struck between the moveable

electrode (negative polarity) and the torch nozzle

(positive polarity) due to a short circuit between these

two elements.

When the torch is brought into direct contact with the

workpiece to be cut (connected to the positive polarity

of the power source) the pilot arc is transferred

between the electrode and the workpiece thus striking

a plasma arc, also called the cutting arc.

The duration of the pilot arc is set in the factory at 3

seconds; if the transfer has not been made within this

time, the cycle is automatically stopped except for the

cooling air which is kept on.

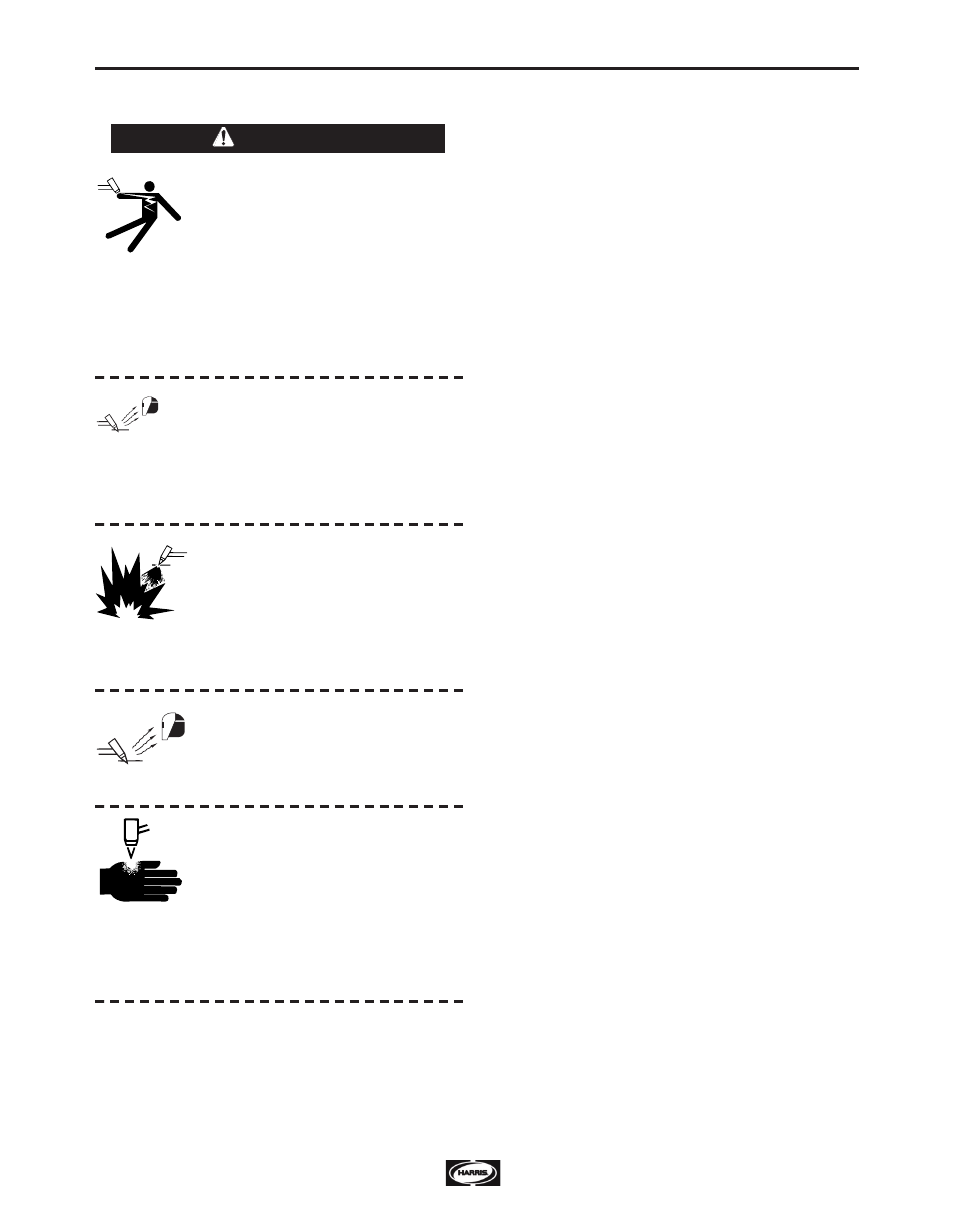

ELECTRIC SHOCK

can kill.

• Do not touch electrically live parts

or electrode with skin or wet

clothing.

• Insulate yourself from work and

ground.

• Always wear dry insulating

gloves.

FUMES AND GASES

can be dangerous.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

WELDING, CUTTING and

GOUGING SPARKS

can cause fire or explosion

• Keep flammable material away.

• Do not weld, cut or gouge on contain-

ers that have held combustibles.

Observe additional Safety Guidelines detailed in

the beginning of this manual.

WARNING

ARC RAYS

can burn.

• Wear eye, ear and body

protection.

PLASMA ARC

can injure

• Keep your body away from nozzle

and plasma arc.

• Operate the pilot arc with caution. The

pilot arc is capable of burning the

operator, others or even piercing

safety clothing.