Operation, Checking air quality, Cutting with a hand torch – Lincoln Electric IM944 POWERTORCH PLASMA 20 User Manual

Page 12: Cutting operations, Warning

B-3

OPERATION

B-3

CHECKING AIR QUALITY

To check air quality, deactivate the torch (post-flow)

and place a welding filter lens in front of the torch. Any

oil or moisture in the air will be visible on the lens. DO

NOT initiate pilot arc while checking air quality.

When preparing to cut, position the machine as close

to the work as possible. Make sure you have all

materials needed to complete the job and have taken

all safety precautions. It is important to follow these

operating steps each time you use the machine.

• COMPRESSED AIR

The POWERTORCH™ PLASMA 20 requires com-

pressed air to be attached to the unit. The input air

pressure minimum must be 72.5 PSI, 5 Bar and

must not exceed 150 PSI, 10.3 Bar. An air regula-

tor is included with the unit with optimum pressure

setting set to 65 PSI, 4.5 Bar.

The unit is also equipped with an air filter which cap-

tures water and oil vapor. The vapor collected can

be drained out of the bottom of the unit by turning

the drain button. The unit will not operate if the

input air pressure is below 55 PSI, 3.8 Bar.

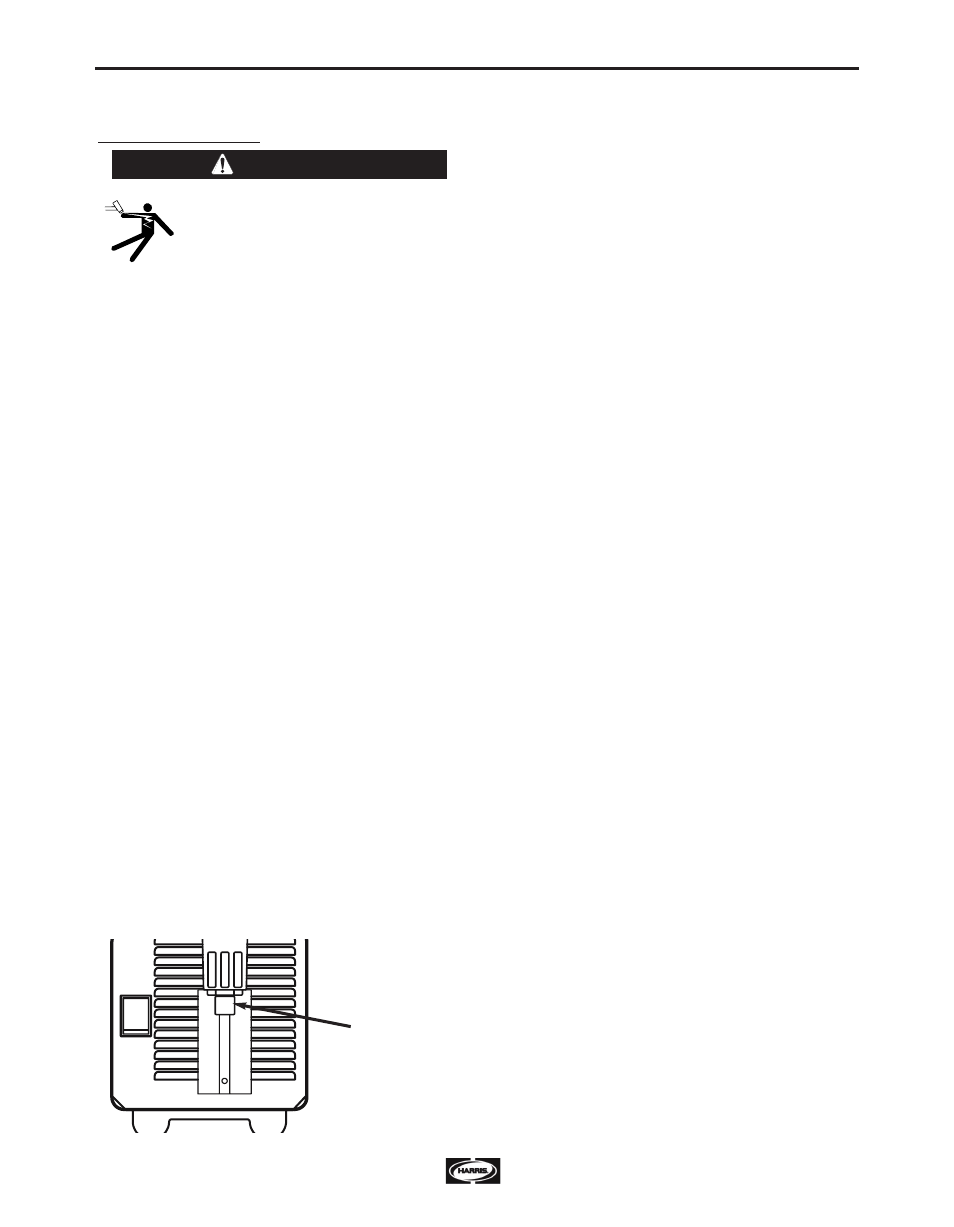

Three Position Drain knob: (See Figure B.1)

1. Open

2. Open when no air pressure, closed when air pres-

sure.

3. Closed

CUTTING WITH A HAND TORCH

• Turn the main power and the machine power switch

on.

- The fan should start.

- The pre-charge circuit will operate for 3 seconds,

then the green "Power" LED should turn on.

• Be sure that the work lead is clamped to the work-

piece before cutting.

• Set the output current control knob at maximum

position for higher cutting speed and less dross for-

mation. Reduce the current, if desired to reduce the

kerf (cut) width, heat affected zone or travel speed

as required.

POWERTORCH™ PLASMA 20

CUTTING OPERATIONS

BEFORE CUTTING

ELECTRIC SHOCK CAN KILL.

Disconnect input power by removing

the plug from the receptacle before

assembling or disassembling torch

parts, or torch and lead assemblies.

------------------------------------------------------------------------

Check and follow instructions listed in the “Safety and

Installation” section of this manual.

TORCH PARTS

Check the torch for proper assembly. Install proper

torch parts for the desired application (refer to the

Torch Consumable Parts Selection Section).

NOTE: The power supply will not operate unless the

torch shield cup is fully seated against the PIP

(Parts in Place) pins in the torch head.

INPUT POWER

Check the power source for proper input voltage.

Make sure the power source meets circuit protection

and wiring requirements.

Plug in power cord to supply input power to the unit.

GROUND CABLE

Check for a solid ground cable connection to the

workpiece.

AUTOMATIC PURGE SYSTEM

Place the ON/OFF switch to the ON position. If the

line voltage is OK, the green LED will turn on. Activate

the torch trigger to initiate air purge. There will be a 3

second delay to remove any condensation that may

have accumulated in the torch and air lines while the

system was shut down. When the air purge (Air safety

time) is complete, pilot arc will be initiated.

FIGURE B.1

WARNING

KNOB