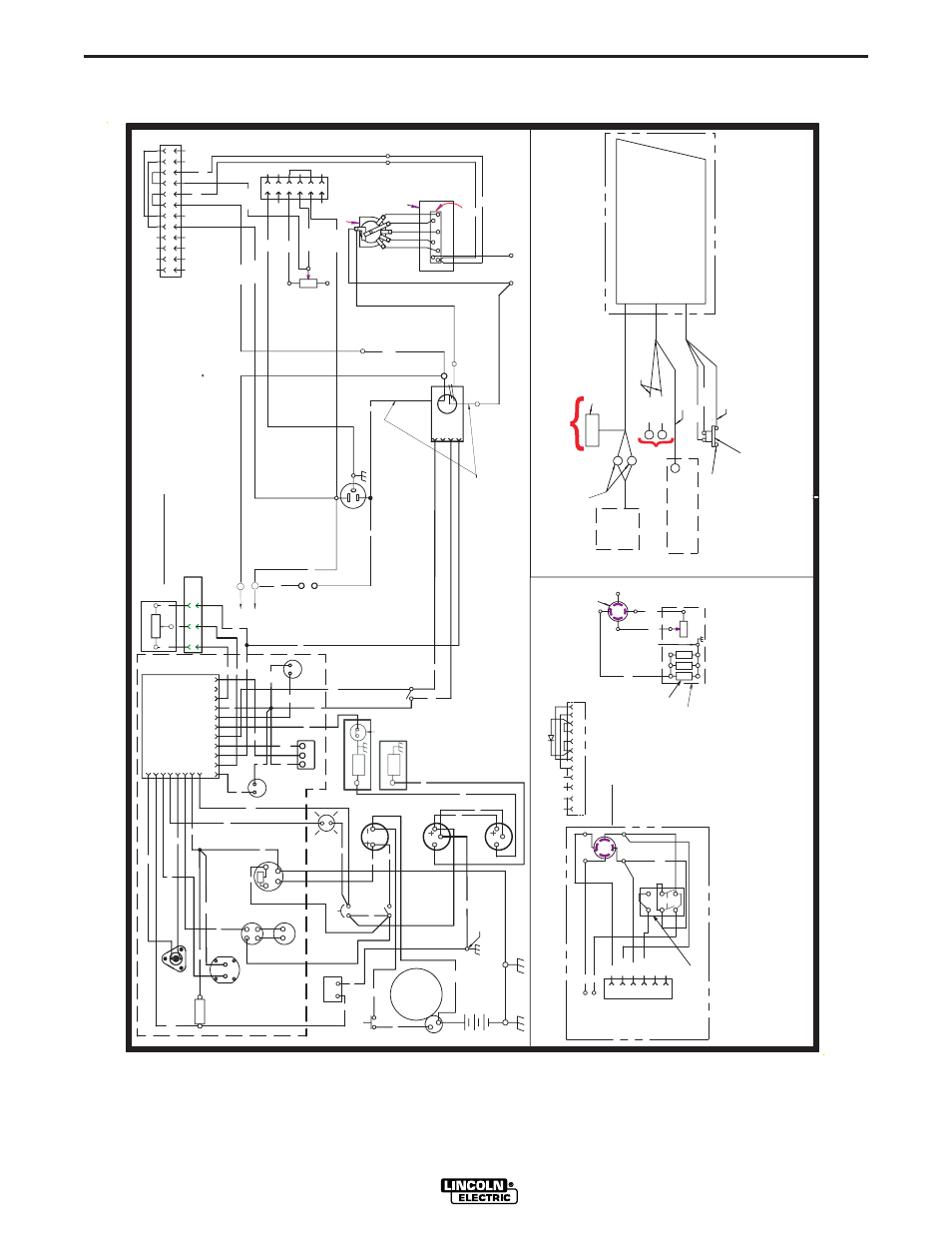

Diagrams, Pipeliner 200g – Lincoln Electric IM698 PIPELINER 200G User Manual

Page 26

F-1

DIAGRAMS

F-1

PIPELINER 200G

A

54

3

2

1

NEGAT

IV

E

SEL

ECT

O

R

SWI

T

C

H

WEL

D

E

R

LE

AD

BL

OCK

42

602A

U

1

2

3

4

5

6

600A

41

GENERAT

OR

N

600B

610

602B

J5

P9

J8

POSI

T

IVE

P1

0

N

U

RHE

OS

T

A

T

(CC-)

(C

C

+) &

(C

V

+ W

IT

H

W

.F

.M

.)

Y

B

W

G

PL

U

G

F

O

R

REMOT

E

CONT

ROL

POT

ENT

IOMET

ER

B

*

P8

1

2

3

4

5

6

X

41

60

0

42

60

2

W

R

BEL

OW

SEE

*

S

W

IT

C

H

F

O

R

L

O

C

A

L O

R

R

E

M

O

T

E

C

O

N

T

R

O

L

SHO

W

N

IN

L

OC

AL

PO

SI

T

IO

N

.

RE

MOT

E

CONTROL

RE

CEP

T

A

CL

E

&

S

W

IT

CH

X

Y

#2

HEAVY

LE

AD

W

IRE

F

EED

M

O

DUL

E

(O

PT

IO

NAL

)

W

IRE

F

EED

MODUL

E

W.

F

.M

.

CO

NT

RO

L

PANEL

NEG.

POS.

OUT

PUT

T

ERMI

NAL

S

CONNECT

T

O

POS.

&

NEG.

CONNECT

T

O

NEG.

B

RUS

H

HOLDE

R

608

609

#2

HEAVY

LE

AD

#8

L

E

A

D

NEGAT

IVE

C

V

OUT

PUT

T

E

RMI

NA

L

PANEL

MACHI

NE

MUST

NOT

BE

RUNNI

NG

W

HEN

MAKI

NG

T

HESE

CONNECT

IONS.

ON

MACHI

NE,

REMOVE

P

LUG

"P

10

"

F

R

OM

CONNECT

OR

"J

5"

.

CONNECT

PL

UG

"P

5"

ON

W.

F

.M.

T

O

CONNECT

OR

"J

5"

ON

MACHI

NE.

PL

UG

(P

5)

200

A

M

P

T

H

ERM

OST

AT

ASSEM

BL

Y

IN

LIN

E

CONNECT

ORS

R

E

MOT

E

C

O

N

T

ROL

PO

T

E

N

T

IO

MET

ER

BOX

L11402

P

IP

E

LIN

E

R

200G

W

IR

IN

G

D

IA

G

R

A

M CODE 10660

CO

N

N

E

CT

T

O

CASE

'

NEUT

RAL

B

ONDED

T

O

F

RA

ME

NE

UT

RE

RACCORDE

AU

BA

T

I

A

K

924-4

R

E

M

O

TE

C

O

N

TR

O

L

(O

P

TI

O

N

A

L)

W

IT

H

M

A

C

H

IN

E

N

O

T

R

U

N

N

IN

G

, R

E

M

O

V

E

P

LU

G

"P

9"

O

N

M

A

C

H

IN

E

F

R

O

M

C

O

N

N

E

C

T

O

R

"J

8"

.

T

H

E

N

C

ON

NE

CT

PLUG

"P

8"

O

N

RE

MO

T

E

C

ON

T

ROL

T

O

C

O

N

NE

CT

OR

"

J8

"

ON

M

A

C

HI

NE

.

CAUT

IO

N:

D

AMAGE

CAN

OCCUR

TO

T

H

E

R

E

M

O

T

E

C

O

N

T

R

O

L

S

W

IT

C

H

IF

IT

IS

U

S

E

D

W

ITH

O

U

T TH

E

"P

11" P

LU

G

F

E

E

D

M

O

D

U

LE

IN

S

T

A

LL

E

D

.

IF A

W

IR

E

F

E

E

D

M

O

D

U

LE

IS

IN

S

T

A

LL

E

D

, W

IT

H

T

H

E

M

A

C

H

IN

E

O

F

F

, D

IS

P

O

S

E

O

F

T

H

E

U

NCO

N

N

EC

T

ED

PL

UG

"

P1

0"

(

IF

O

N

E

IS

O

N

T

H

E

M

ACH

INE)

F

AST

EN

T

HE

NEW

PL

UG

"

P1

1"

N

EAR

BY,

L

EAV

IN

G

IT

UN

CO

NN

ECT

ED.

IF

N

O

W

IR

E

F

E

E

D

M

O

D

U

LE

IS

IN

S

T

A

LL

E

D

, W

IT

H

TH

E

M

A

C

H

IN

E

O

F

F

, D

IS

C

O

N

N

E

C

T

P

LU

G

"P

10

"

O

N

TH

E

M

A

C

H

IN

E

FR

O

M

C

O

N

N

E

C

TO

R

"J5". C

O

N

N

E

C

T

P

LU

G

"P

11

"

FR

O

M

TH

E

R

E

M

O

T

E

C

O

N

T

R

O

L

K

IT

TO

C

O

N

N

E

C

T

O

R

"J5

"

O

N

TH

E

M

A

C

H

IN

E

.

SEE

BEL

OW

SHOW

N

AS

VI

EW

ED

F

R

OM

REAR.

CONT

ROL

P

ANEL

COMPONENT

S

1

2

3

4

5

6

7

8

9

10

11

12

**

**

CURRENT

SENSO

R

C

A

U

T

IO

N

: D

A

M

A

G

E

C

A

N

O

C

C

U

R

T

O

T

H

E

R

E

M

O

T

E

C

O

N

T

R

O

L S

W

IT

C

H

IF

IT

IS

U

S

E

D

W

IT

H

O

U

T

T

H

E

"P

11

" P

LU

G

IN

S

T

A

LL

E

D

O

R

A

W

IR

E

F

E

E

D

M

O

D

U

LE

IN

S

T

A

LL

E

D

.

O

N

P

IP

E

LI

N

E

R

200G

M

A

C

H

IN

E

S

, C

O

N

N

E

C

T

R

E

D

A

N

D

B

LA

C

K

L

E

A

D

S

O

N

R

E

M

O

TE

T

O

E

TO

EXCI

T

E

R

OUT

P

UT

RED

AND

BL

AC

K

LEAD

S

O

N

M

AC

HI

NE.

R

FO

R

REMOT

E

O

P

TIO

N

B

W

3

2

1

4

RESI

ST

O

RS

IN

ST

AL

LE

D

O

R

A

W

IR

E

1

2

3

4

5

6

7

8

9

10

11

12

P1

1

E

BEL

O

W

SEE

*

REC

EPT

ACL

E

B

EL

ECT

R

IC

AL

SYMBOL

S

LE

AD

COLOR

CODE

PER

E

15

37

B

-

BL

ACK

G

-

GREEN

N

-

BROW

N

R

-

RE

D

U

-

B

LUE

W

-

WH

IT

E

Y

-

YEL

LOW

+

-

+

84

-

51

60

EXC

+

70

S

B

+

GR

O

U

ND

T

O

BASE

GR

O

U

ND

TO

E

N

G

IN

E

3

4

5

14

61

62

15

19

Z

E

N

ITH

THR

OT

TL

E

BODY

CONT

ROL

LE

R

71

72

82

81

76

74

73

83

99E

78

99

80

89

21

22

+

-

-

W

H

IT

E

CONNECT

O

R

BL

ACK

CONN

E

CTOR

11

9

8

5

4

3

1

17

13

-

+

96

99D

87A

WA

T

E

R

TE

M

P

.

SENSO

R

A

B

AI

R

TE

M

P

.

SENSOR

95

CB

5

AB

C

93

#

IN

JE

C

T

O

R

T

H

ROT

T

LE

PL

AT

E

MOT

O

R

A

B

92

91

90

97

97A

99B

99C

67

2

M

AP

SENSO

R

12

COI

L

DI

S

T

RI

B

U

TOR

ID

LE

R

SW

IT

CH

AL

T

E

RN

AT

OR

IG

N

IT

IO

N

SWI

T

CH

ST

ART

ER

MO

T

O

R

EN

GI

NE

HOUR

MET

ER

ENGI

NE

FA

IL

UR

E

LA

M

P

ST

ART

W

A

TE

R

TE

MP

.

GAUG

E

S

A

B

94

F

U

EL

PUM

P

77

O

IL

PRESS. GA

U

G

E

S

CONTROL PANEL

GROUND SCREW

69

45

R

G

87

99A

97B

97C

50

87B

10

K

RP

M

CONT

R

OL

4

3

1

2

3

2

1

AMM

ET

ER

SENS

O

R

WA

TER

T

EM

P.

SE

N

DER

SENS

O

R

O

IL

P

RESSU

RE

S

W

IT

C

H

&

SE

NS

O

R

SW

IT

CH

WK

G

PAR

T

S

SU

PPL

IED

W

IT

H

E

N

G

IN

E

610B

T

HESE

LEAD

S

MUST

BE

ROUT

ED

T

HRU

CU

RRENT

SENSOR

IN

T

HE

SAM

E

(CU

RRENT

F

LOW

)

DI

RECT

ION

AS

SHOW

N.

NOTE: This diagram is for reference only. It may not be accurate for all machines covered by this manual. The specific diag

ram for a particular code is pasted

inside the machine on one of the enclosure panels. If the diagram is illegible, write to the Service Department for a replacem

ent. Give the equipment code number.