Troubleshooting, Electronic idler control troubleshooting guide, Caution – Lincoln Electric IM698 PIPELINER 200G User Manual

Page 25

E-7

TROUBLESHOOTING

E-7

PIPELINER 200G

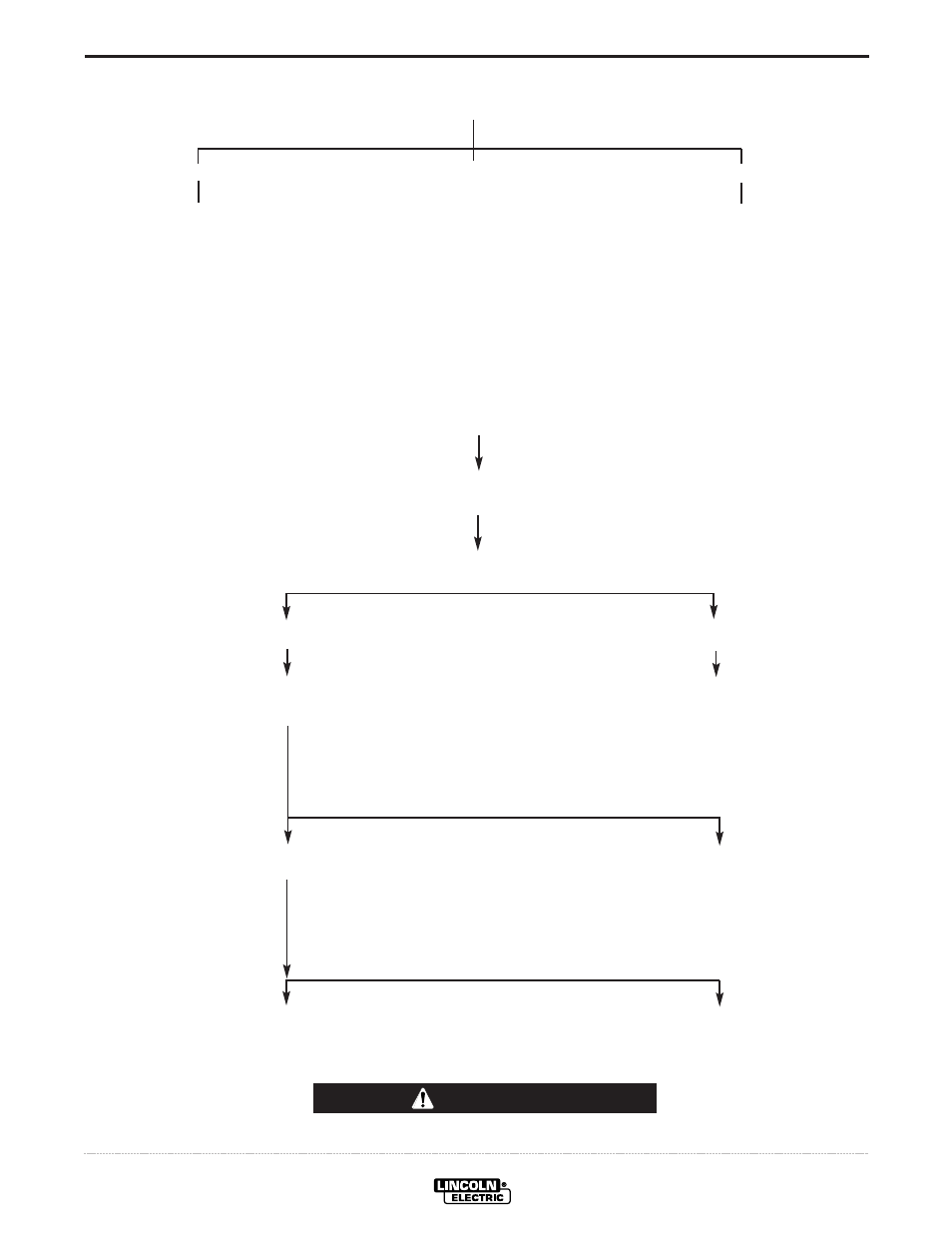

ELECTRONIC IDLER CONTROL TROUBLESHOOTING GUIDE

Engine Will Not Return to Low

Idle in Approximately 10 Seconds

After Welding and Auxiliary Loads are Removed

Set Idler Control Switch

to the Auto Position

Check for Continuity through Idler

Control Switch

Open

Closed

Remove Molex connector

Replace Idler

from current sensing board.

Control Switch.

Operation Same

Machine Idlers

Check wiring between TBI controller and current sensing board.

1. Check for current in wires looping through

current sensor.

2. Replace current sensor.

Have TBI controller inspected at authorized service shop.

Not O.K.

Correct wiring

With Idler Control Switch in the AUTO Position,Engine Will Not Pick Up Speed When:

Auxiliary Load

1. Load too small. Try load

above 150 Watts.

2. Check for loose or

disconnected wire running

from black lead out of exciter

to CB2 circuit breaker.

The Arc is Struck

Check for loose or disconnected

wire running between weld

selector switch and output stud.

Both

1. Check Idler circuit wiring. Possible

problems are wires from Current

Sensing Board reversed at idler

switch or wires connected incorrectly

at Current Sensor Molex plug.

2. Replace current Sensing Board.

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your

Local Lincoln Authorized Field Service Facility

for technical troubleshooting assistance before you proceed.

CAUTION