Installation, Miller power source, Lincoln wire feeder – Lincoln Electric IM872 LF-74 WIRE FEEDER User Manual

Page 15

A-7

INSTALLATION

LF-74

A-7

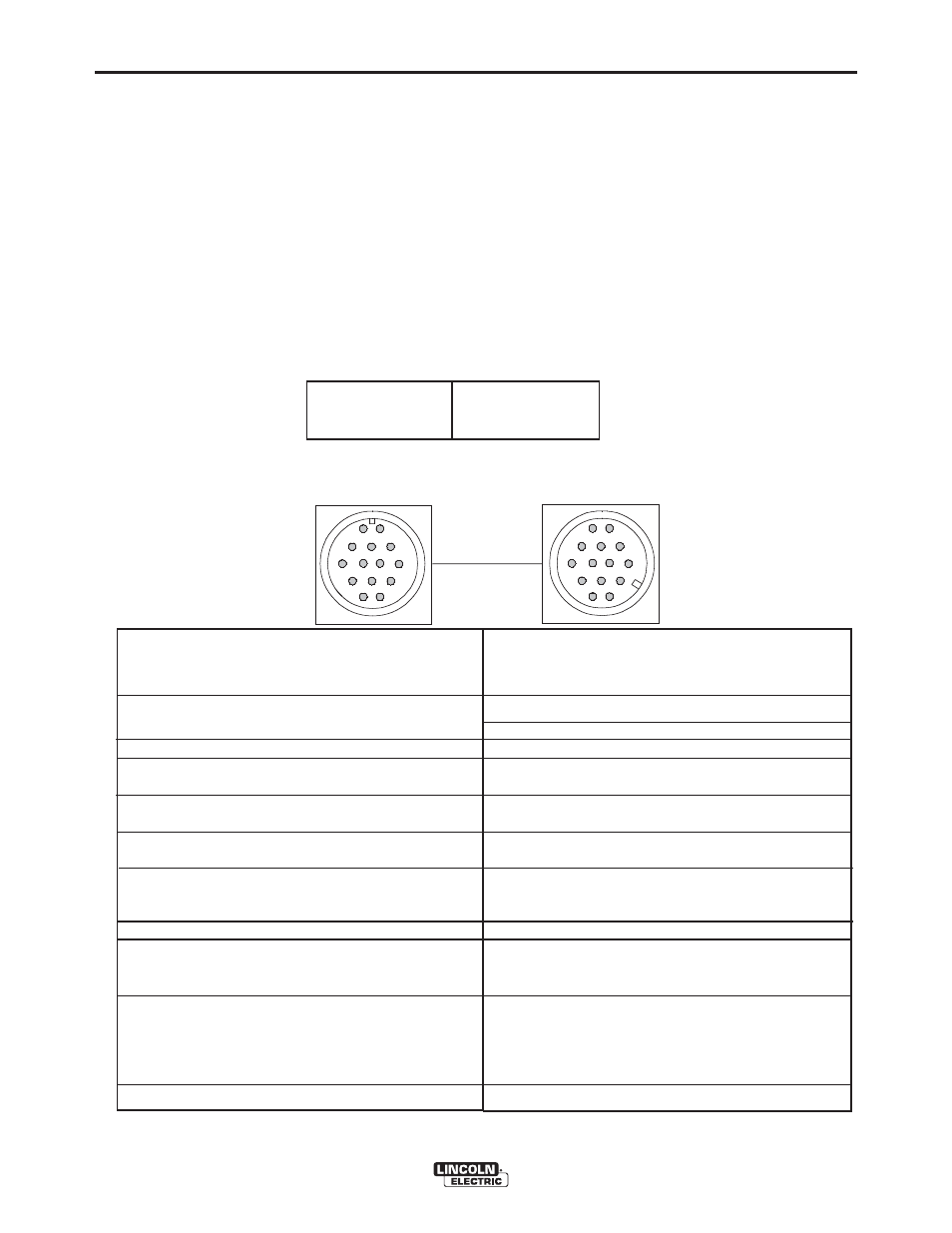

ANALOG MILLER CONTROL CABLE

ADAPTER K2335-1

This Lincoln Electric wire feeder may be mounted to a

limited number of Miller Electric power sources. The

Miller power source must have the circular connector

pin definition shown in the table below for proper oper-

ation of the wire feeder. Be sure the Miller power

source provides 24 VAC to the wire feeder and has

overcurrent protection of no more than 15 amps. The

power source must not exceed 113VDC peak.

Operation of Lincoln wire feeders on Miller power

sources may result in lack of high wire feed speeds or

reduced pull force at high wire feed speeds.

Approximate maximum WFS for Lincoln wire feeders

operating with 24 VAC:

A

B

C

D

I

E

F

G

H

J

K

L

M

N

A

I

H

G

B

F

E

D

C

J

K

N

M

L

WIRE FEEDER

POWER SOURCE

MILLER POWER SOURCE

Pin

Function

A

24 VAC to feeder

B

Welding Output Control

C

+10VDC to feeder for remote control

D

Remote control common

E

0-10VDC from feeder for remote control.

F

Current feedback to feeder.

Scaled 0-10V. 1 V = 100 amps.

Referenced to pin D.

G

24 VAC common.

H

Arc Voltage feedback to feeder.

Scaled 0-10V. 1 V = 10 Arc volts.

Referenced to pin D.

N

LINCOLN WIRE FEEDER

Pin

Function

I

42 VAC feeder

D

Welding Output Control

C

Welding Output Control

E

Remote Voltage Control ("+" supply, from

power source)

G

Remote Voltage Control ("-" supply, from

power source)

F

Remote Voltage Control (control signal from

feeder or remote.)

J

Reserved for future use.

K

42 VAC to feeder

L

Reserved for future use.

N

Electrode voltage to power source (67)

Miller is a registered trademark not owned or licensed by The Lincoln Electric Company.

LF-72

LF-74

LF-74, extra torque

720 ipm

720 ipm

360 ipm