Installation – Lincoln Electric IM872 LF-74 WIRE FEEDER User Manual

Page 13

A-5

INSTALLATION

LF-74

A-5

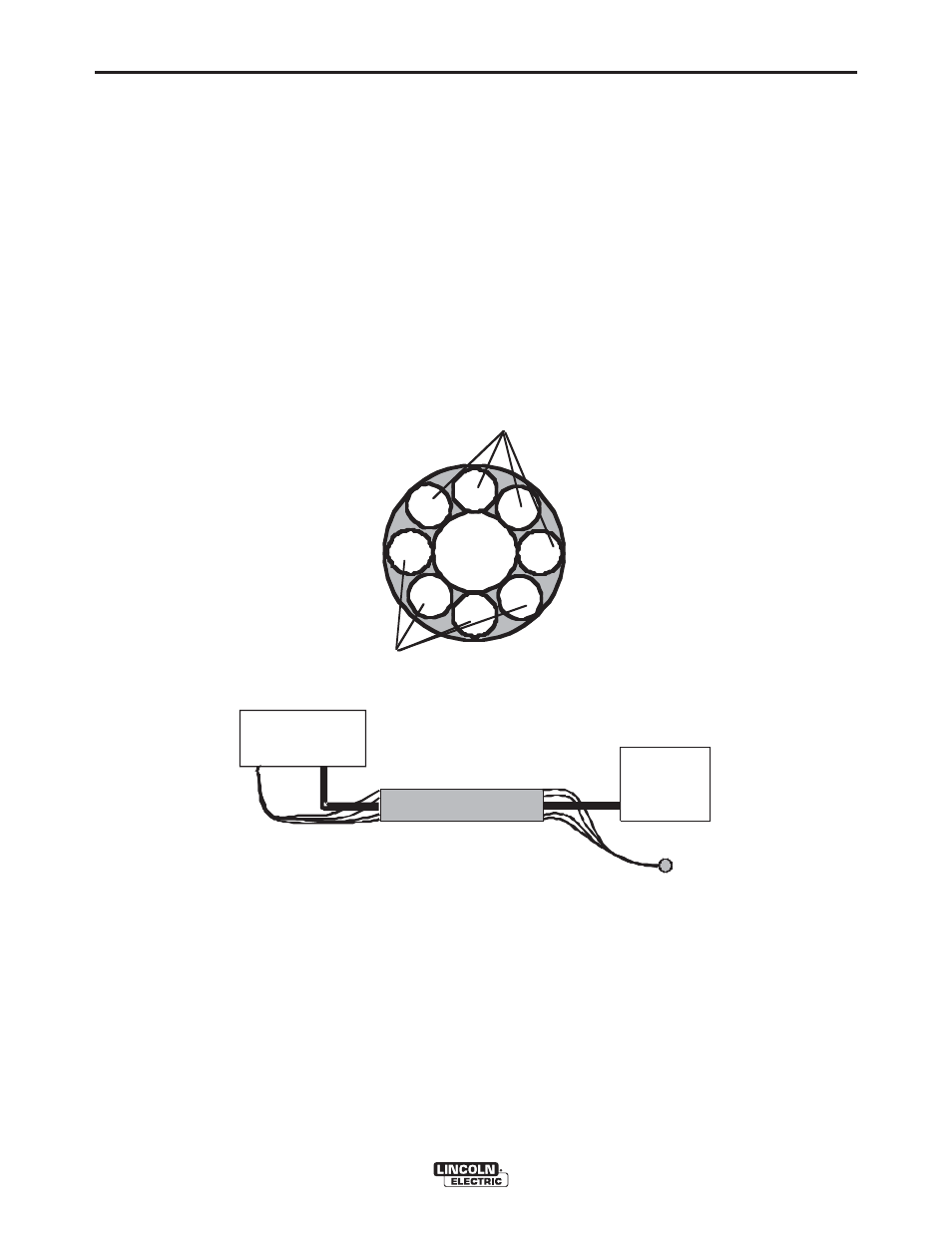

COAXIAL WELD CABLES

Coaxial welding cables are specially designed welding

cables for pulse welding welding. Coaxial weld cables

feature low inductance, allowing fast changes in the

weld current. Regular cables have a higher induc-

tance which may distort the pulse wave shape.

Inductance becomes more severe as the weld cables

become longer.

Coaxial weld cables are recommended for all pulse

welding, especially when the total weld cable length

(electrode cable + work cable) exceeds 50 feet

(7.6m).

A coaxial weld cable is constructed by 8 small leads

wrapped around one large lead. The large inner lead

connects to the electrode stud on the power source

and the electrode connection on the wire feeder. The

small leads combine together to form the work lead,

one end attached to the power source and the other

end to the work piece. (See Coaxial weld Cable below.)

WELD CABLE CONNECTION

Connect a work lead of sufficient size between the

proper output stud on the power source and the work.

Be sure the connection to the work makes tight metal

to metal electrical contact. Poor work lead connec-

tions can result in poor welding performance.

Electrode

Work

Work

Power Source

Work

Electrode

Wire Feeder

Electrode

Work

Coaxial Weld Cable