Installation, Caution warning – Lincoln Electric IM876 eCELL WIRE DRIVE SYSTEM User Manual

Page 14

A-7

INSTALLATION

eCELL

™

WIRE DRIVE SYSTEM

A-7

SETTING ELECTRODE POLARITY

ELECTRIC SHOCK can kill.

• Turn the input power OFF at the dis-

connect switch before working on

this equipment.

• Do not touch electrically hot parts.

• Only qualified personnel should install, use or

service this equipment.

When changing the electrode polarity, the weld

cables must be changed at the power source

studs and the DIP switches inside the eCell™ Wire

Drive System must be properly set. Operation

with the DIP switch in the wrong position will

cause erratic arc performance.

------------------------------------------------------------------------

The eCell™ Wire Drive is factory set for Electrode

Positive welding.

Most GMAW welding procedures use Electrode

Positive welding. Some Innershield procedures may

use Electrode Negative welding.

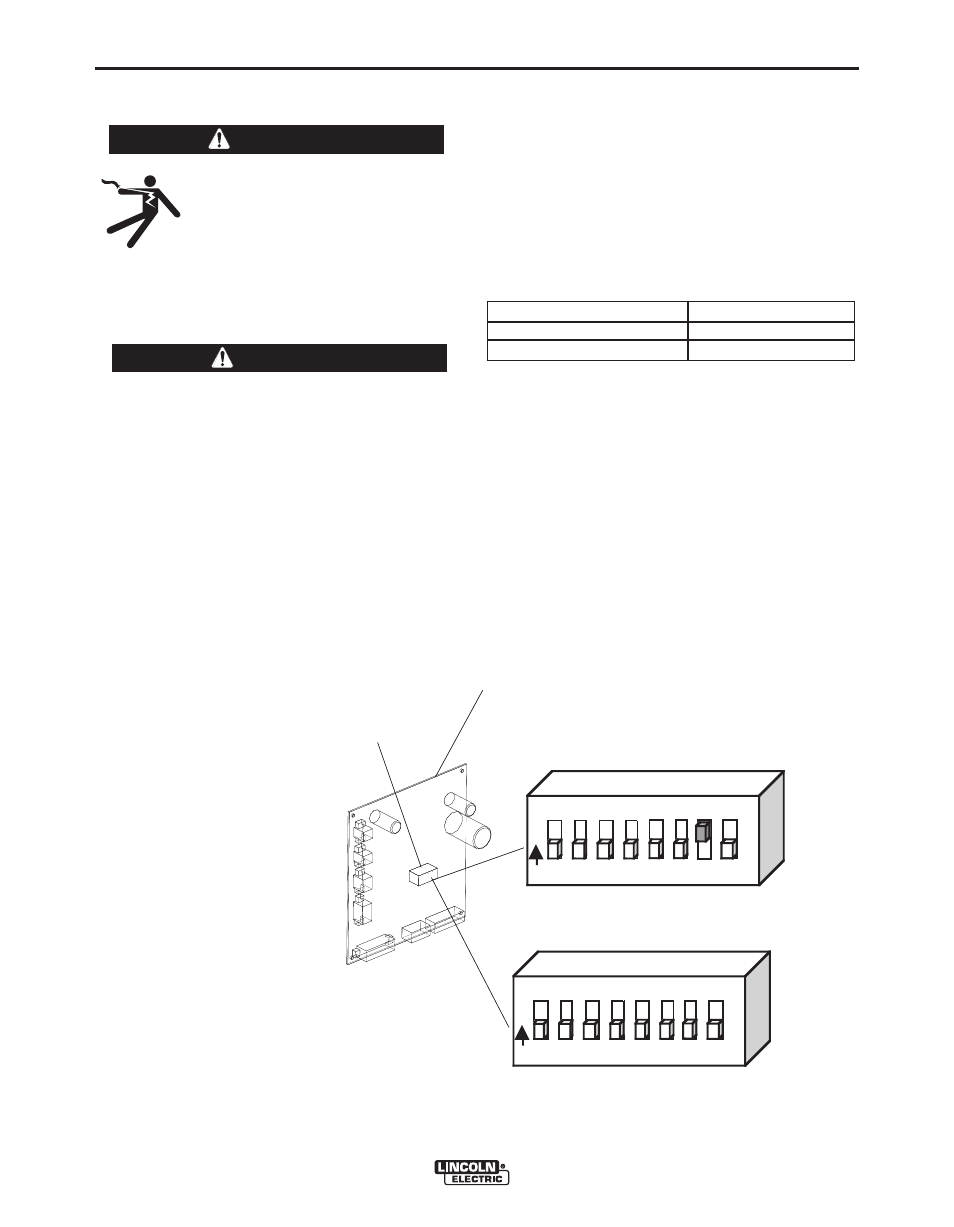

To change the DIP switch inside the eCell™ Wire

Drive for electrode polarity: (See Figure A.5)

1. Turn off power at the welding power source.

2. Remove the sheet metal wrap-around on the wire

drive.

3. Locate DIP switches on the Wire Drive Board.

4. Set DIP switch #7 to the desired polarity.

DIP Switch #7 Position

Polarity

ON

- (negative) polarity

OFF

+ (positive) polarity

5. Assemble the wrap-around to the wire drive.

6. Restore power.

1 2 3 4 5 6 7 8

O

N

- (Negative) Polarity

LOCATION DIP SWITCH

1 2 3 4 5 6 7 8

O

N

+ (Positive) Polarity

eCELL WIRE DRIVE BOARD

FIGURE A.5

CAUTION

WARNING