Stuart Turner Boostamatic2/T12-2 User Manual

Page 18

- 18 -

Dry Run Protection

This pump is fitted with a safety control circuit, which will detect the following fault

condition:

Dry running caused by water starvation to the pump.

Should the pump run out of water it will stop as part of a “protective logic sequence”,

detailed below.

The fault should be rectified before re-starting the pump. Check that there is sufficient

water supply to the pump and also ensure that all terminal fitting outlets are closed.

Protective Logic Sequence

If water starvation occurs and the power supply to the pump remains uninterrupted, the

pump controller will perform the following protective sequence.

1. If the pump detects water starvation, it will stop operation after a 1 minute period.

2. The pump will remain in the off condition for a period of 5 minutes.

3. The pump will then re-start and if the water starvation condition remains present, the

pump will then stop operation after a 1 minute period.

4. The pump will remain in the off condition for a period of 5 minutes.

5. The pump will then re-start and if the water starvation condition remains present, the

pump will then stop operation after a 1 minute period.

6. The pump will remain in the off condition for a period of 5 minutes.

7. The pump will then re-start and if the water starvation condition remains present, the

pump will then stop operation after a 1 minute period.

8. After three consecutive resets are performed the pump will remain in the off

condition

indefinitely.

9. To restart the pump, the power supply should be first isolated for a period of at least

10 seconds before switching on again.

If the pump fails to operate normally after three attempts to re-start, then please contact

the Pump Assist team on 0844 98 000 97.

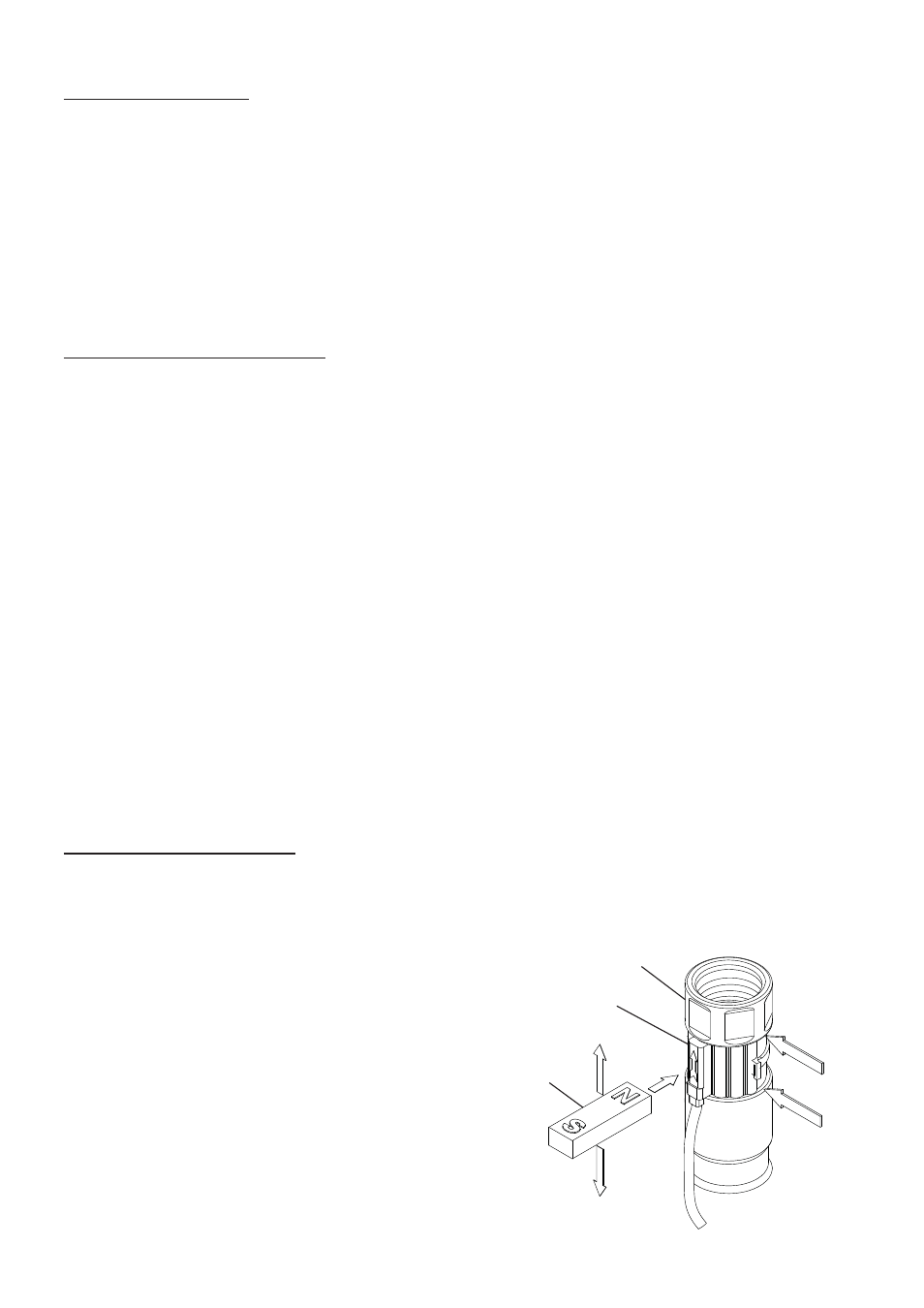

Flow Switch Circuit Test

1. First confirm visually that the flow switch reed clamp have not been dislodged during

handling or installation. The clamp must be fully located within the flow switch body

groove as shown.

2. To carry out the following test you will need to obtain

a magnet, a typical fridge magnet is suitable.

3. Ensure the power supply is switched on.

4. Position the magnet directly in front of the reed

clamp as shown. If pump does not start, then

slowly move the magnet up and down to a

position that exceeds the extent of the reed

clamp. The pump should instantaneously start

at some point during this extent of movement.

If this does not happen, this indicates a possible

fault with the reed switch or the P.C.B which is

located within the terminal box. These should be

checked electrically. Consult Stuart Turner for further instructions.

Fig. 21

Groove

Body

Reed

Clamp

Magnet