Stuart Turner Boostamatic2/T12-2 User Manual

Page 13

- 13 -

Cont ...

Supply Cord Replacement

If the supply cord needs to be replaced, cord selection should be chosen in accordance

with the current involved, surrounding conditions and recommended fuse size. For

information on cable fitting and connection, consult the wiring diagram and cable gland

fitting instructions.

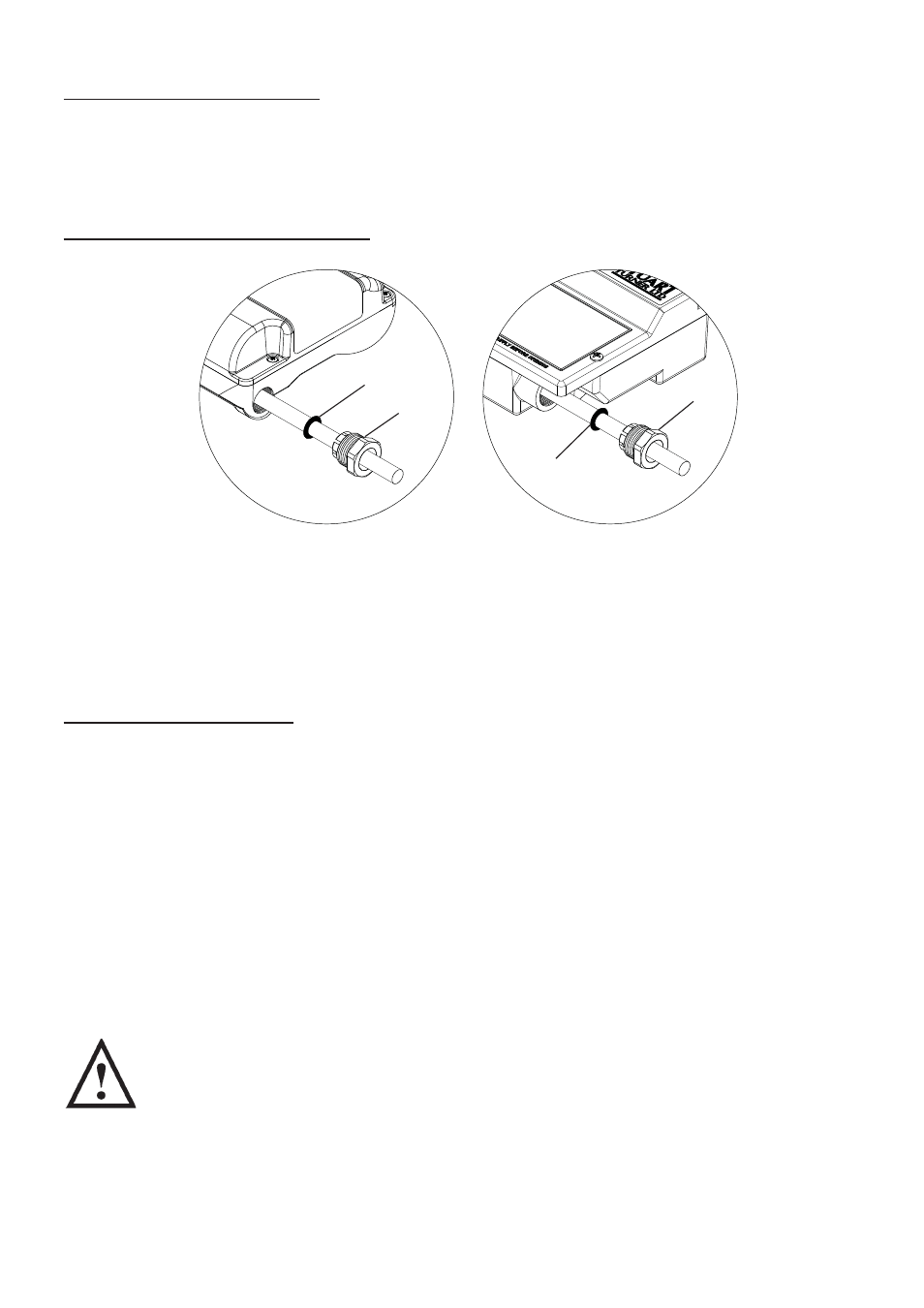

Cable Gland Fitting Instructions (Motor Terminal Box)

To enable correct assembly of the cable gland, the ‘O’-ring (Fig. 16 item 1) must be

placed over the cable before the clamping insert (Fig. 16 item 2) can be tightened as

shown.

Note: Cable diameter range:- 6.5 mm to 9.5 mm.

Supply Cord Extension

The pumps are fitted with a supply cord to the following specifications:-

4000, 6000, K7-2:- . . . . . . . . . . . . . . HO5VV-F3 G 0.75 mm² - 6 Amp rating.

L5-4S, L7-4S, T6-2, T12-2:- . . . . . . . HO7RN-F3 G 1.0 mm² - 10 Amp rating.

If the supply cord is to be extended, a cord of the same specification should be used.

Any connections or junction boxes used should be specifically suited for the application

and installed in accordance with the manufacturers instructions.

NOISE

The equivalent continuous A-weighted sound pressure level at a distance of 1 metre

from the pumpset does not exceed 70 dB(A) for all models.

COMMISSIONING

WARNINGS:

The motor casing can become very hot under normal operating

conditions, care should be taken to ensure it cannot be touched

during

operation.

Do not run pump without guards and terminal box lids correctly fitted.

Care should be taken to protect the pump from freezing.

The pump chamber must be full of liquid at all times. Seal damage will

result if the pump runs dry.

Fig. 16

L5-4S, L7-4S

T6-2, T12-2

4000, 6000, K7-2

1

1

2

2