Sterling EV User Manual

Page 9

–

9

–

Bleed-Off

Bleed-Off is required to maintain the water quality of

the system. When water evaporates, minerals and

other impurities are left behind, impurities are scrubbed

from the air fl owing through the system, and make-up

water (even good quality make-up water) adds more

minerals and impurities. These form deposits on the

media during the evaporative process.Therefore, it is

important to bleed-off a small quantity of recirculating

water to keep the concentration of impurities under

control. The bleed-off rate required is dependent upon

the quality of the water used and the rate of evaporation.

As climate conditions change, the rate of evaporation

may increase, requiring an increase in the bleed-off rate.

It is recommended that the bleed-off rate be adjusted

for the maximum water evaporation. An indication of

insuffi cient bleed-off is a uniform build-up of minerals

on the entering air face of the media. If this condition is

observed, increase the rate of bleed-off until the mineral

deposits dissipate.

Adjusting the Bleed-Off

1. The bleed-off is attached to the PVC tee. This

bleed-off system will eliminate a small quantity of

water from recirculation, which will reduce scale

build-up. This water will drain through the attached

tube, and out through the overfl ow. Disposal of this

water should comply with local codes.

2. Adjust the bleed-off rate according to Table 4.

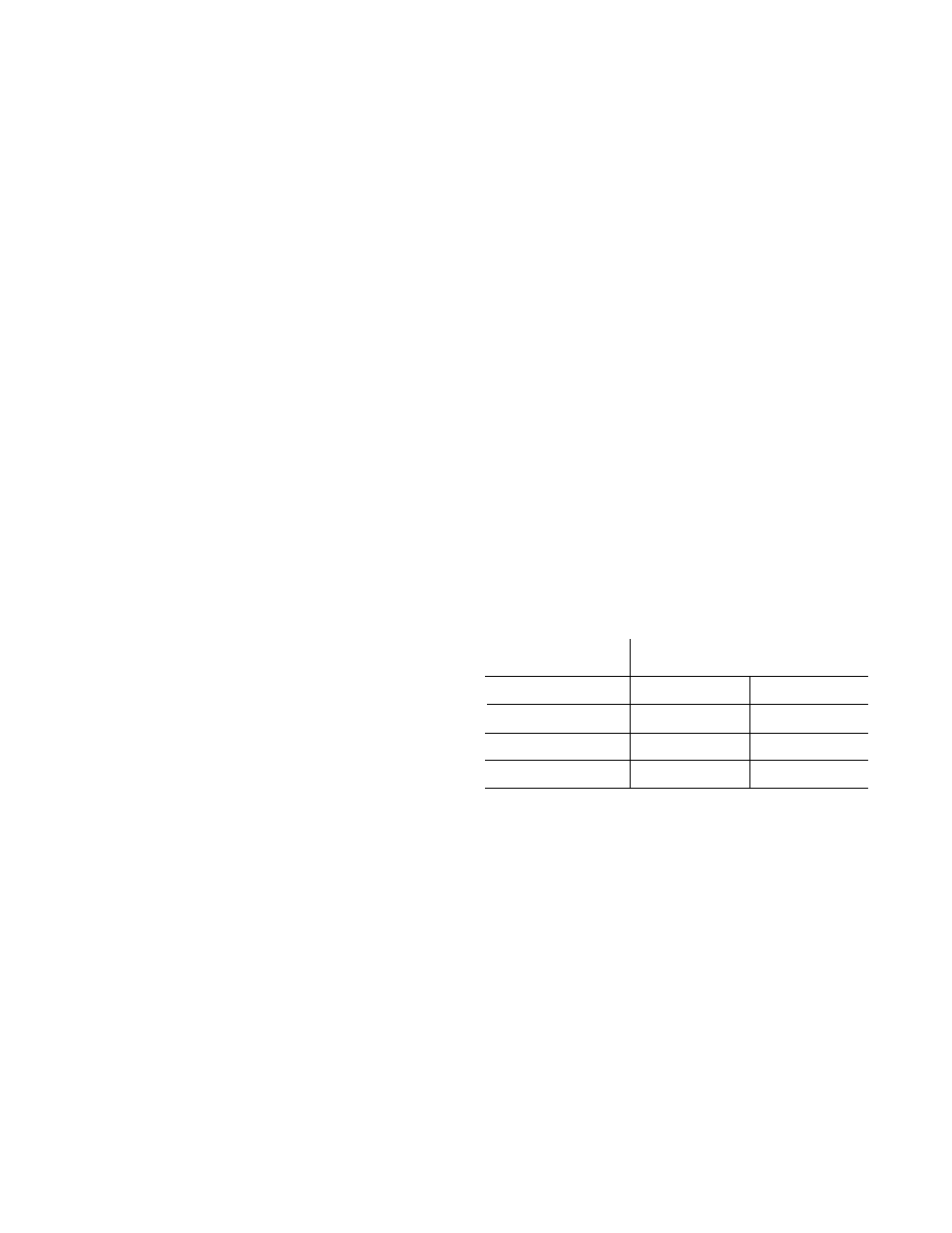

Table 4

Unit Size

Seconds to Fill

Capacity

12 oz. Can

10/15

69

46

20/25/50

52

34

30/35/60/70

41

27

40/80

38

25

Adjusting the Water Level and Float Valve

Fill the tank as follows:

1. Turn the water supply on. Fill the tank to a depth of

approximately 3.25" (82.6mm). While fi lling the tank,

check for good pressure and fl ow from the fl oat

valve.

2. The fl oat valve should shut down the water supply

at the 3.25" (82.6mm) level. It may be necessary to

adjust the fl oat valve by bending the rod. The rod

level adjustment screw should be set in lower notch

on lever.

3. Check the tank and all connections for leaks.

NOTE: The overfl ow fi tting is set so that the water

will begin to fl ow at the 3.25" (82.6mm) depth. It is

important that the water level not be above the pump

basket screen!

Adjusting the Water Flow

Proper water flow over the media is important.

Insufficient water flow will result in increased

accumulation of minerals on the media. Excessive water

fl ow will result in deterioration of the media and moisture

carryover.

1. Using the ball valve handle, adjust the water fl ow so

that the media is damp from the top to the bottom. If

you can see water fl owing on the entering side, your

water level is too high. Adjust the valve so that the

media is just damp on the entering side. Repeated

drying of the media will cause rapid buildup of

mineral deposits in the media. Drying is due to

improper adjustment of the water fl ow valve, frequent

shut-down of the pump to control the evaporative

cooling/humidifi cation, or localized air velocities

across the surface of the media. The area where dry

spots occur will exhibit high mineral deposits. The

valve must be adjusted so that no dry spots appear

on entering or leaving side, and when adjusted

correctly, enough water will fl ow through the media to

wash out most of the airborne dirt and other debris.

2. Prior to start-up, it is recommended that the tank

be fi lled, and the pump turned on, allowing the

unit to run for approximately 10 minutes. Repeat

this procedure two times to help fl ush any dirt that

may have accumulated during shipping.