Sterling EV User Manual

Page 13

–

13

–

Washing the Media

Avoid splashing water on the blower

motor at all times (this could cause electrical

problems)!

1. Scale and dust should be washed off the intake side of

the media annually, using a garden hose and nozzle;

this will help to unclog passages.

2. Using a stiff brush, lightly brush the intake edges of

the media. This will not harm the openings, but will

remove any hardened scale.

3. Occasionally, there will be a build-up of algae or odors.

The best solution for both of these problems is to

allow the pads to dry thoroughly on a regular basis.

If cooling is not needed at night during the cooling

season, allow the blower to run for a few hours after

the pump has been shut-down to dry pads daily.

4. During the cooling season, we recommend that

the pads be shut down nightly if possible with the

blower running to dry the pads out for a few hours

before the unit is shut down.

Washing the Inlet Filter

The pre-fi lter should be cleaned periodically as follows:

1. Turn the four latches and remove filter frame

assemblies.

2. Carefully remove the aluminum fi lters. Wash the fi lters

with warm water and a mild soap, rinse thoroughly.

3. Re-install in unit.

4. If the aluminum mesh fi lters are damaged or cannot

be cleaned, replace the mesh fi lter (See replacement

parts section).

Cabinet Cleaning and Touch-Up

The cabinet and all internal parts of the Evaporative Cooler

should be cleaned annually using a soft cloth, warm water,

and a mild cleanser.

NOTE: Avoid using steel wool or sandpaper in normal

cleaning of the unit.

Winter Shut Down

1. Clean and fl ush out Evaporative Cooler media and

sump.

2. Clean water distributor holes.

3. Drain fi ll pipe and leave open. DO NOT LEAVE ANY

WATER IN THE SYSTEM. FREEZING CAN CAUSE

MAJOR DAMAGE TO THE UNIT.

4. Remove and clean pump if necessary.

5. Check sump tank for leaks and repair if necessary.

Sump tank is fabricated from stainless steel.

6. Replace with new CELdek

®

media sections. (See

replacement part section).

Aspen and other evaporative media will not work.

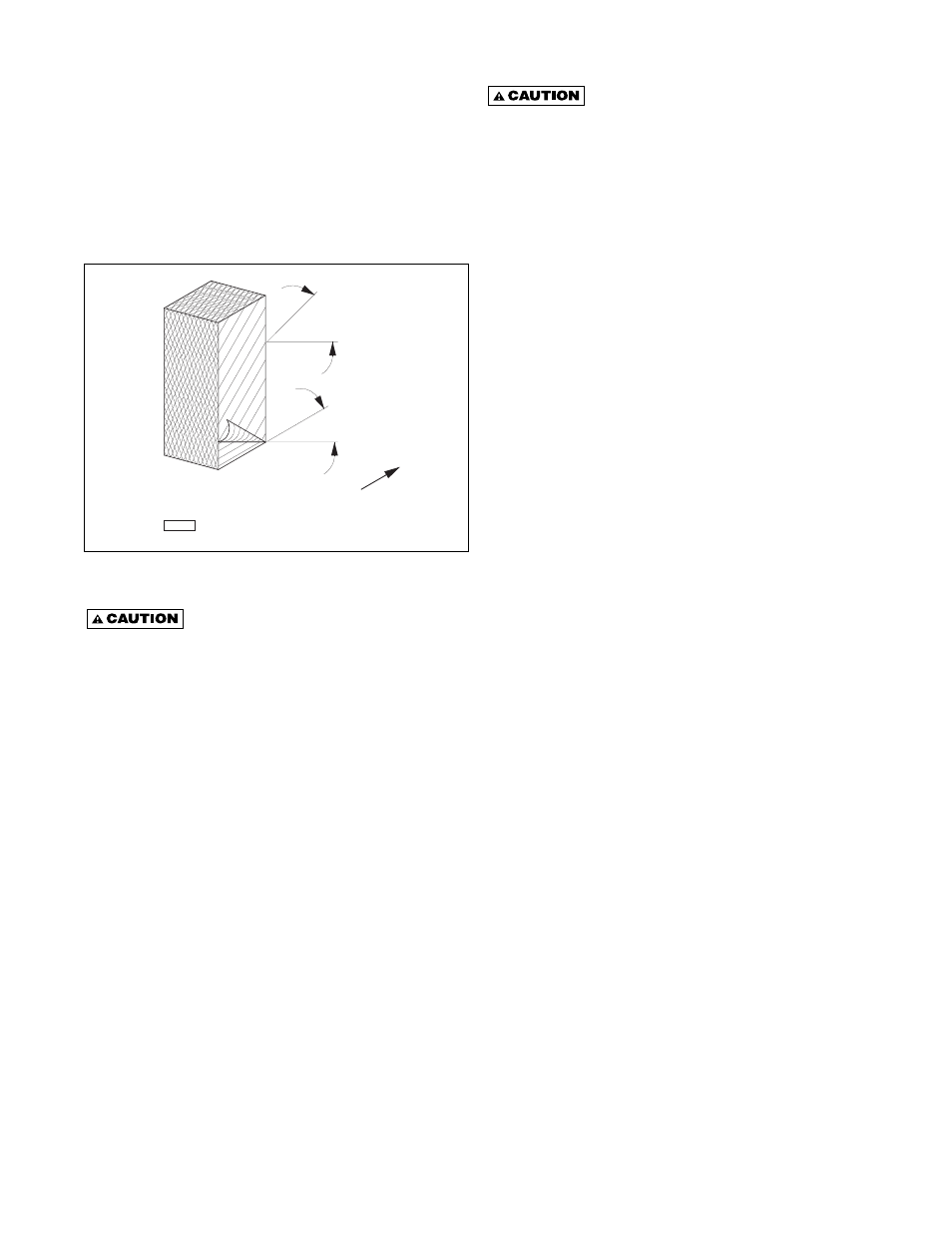

7. When re-installing media, be sure all media

sections are installed in the proper direction. See

Figure 11.

8. Replace top media distribution pad, water dis-

tribution system, water hood panel, and fi lter/frame

assemblies.

Figure 11 - Evaporative Cooling Media Pad Section

Cleaning the Water Pump

Do not allow the pump to topple over

or become submerged. Water will damage the pump

motor. This is not a submersible pump.

Disassemble and clean water pump as follows:

1. Disconnect

power.

2. Disconnect the liquid tight connector from the

junction box to remove cord and connector.

3. Disconnect the pump mounting bracket and hose.

4. Remove the pump and basket screen.

5. To clean pump, snap out base of the pump; notice

the impeller.

6. Using a mild detergent solution, wash all deposits

from the impeller and the impeller base plate.

7. Spin the impeller to dislodge any foreign material.

Make sure that the impeller spins freely.

8. Carefully snap the impeller and impeller base plate

back onto the pump.

9. Wash the pump basket screen using the same

detergent solution, and rinsing thoroughly to remove

any debris. If unable to clean, replace with a new

screen (See replacement part section).

NOTICE: The pump motor does not require any

lubrication.

45° TYP.

15° TYP.

AIR FLOW

D3883