Steam calculations and correction factors – Sterling VS User Manual

Page 7

7

EXAMPLE: –

UNIT SIZE __________ 40

Steam Pressure ___10 PSI

Entering

Air

Temp.

__ 40°F

I. CAPACITY

A. For 2 lbs. steam, 60°F entering air

Read output directly from Table 3: 41,300 BTU/HR.

B. For higher steam pressures

Multiply output from Table 3 by appropriate correction

and/or EAT’s above or below 60°F

factor from Table 5 (below).

41,300 x 1.27 = 52,451 BTU/HR.

II. FINAL AIR TEMPERATURE

A. For 2 lbs. steam, 60°F entering air

Read temperature directly from Table 3: 124°F.

B. For capacities calculated in IB (above)

Output from IB

+ EAT = Final Air Temp

52,451

+ 40 = 121.0°F

1.085 x CFM from Table 3

1.085 x 595

III. FINAL AIR VOLUME

Nom. CFM Final

A. For 2 lbs. steam, 60°F entering air

460 + Final Air Temp from Table 3 from = Air

460+124 x 595 = 655 CFM

530 Table 3 Volume

530

Nom. CFM Final

B. For fi nal air temperatures calculated

460 + Final Air Temp from IIB from = Air

460+121.0 x 595 = 652 CFM

In IIB (above)

530 Table 3 Volume

530

IV. CONDENSATE PER HOUR

A. For 2 lbs. steam, 60°F entering air

Read lbs. per hour from Table 3: 43 LBS./HR.

B. For capacities calculated in IB (above)

Output from IB

= lbs. per hour of condensate

52,451

= 55.0 LBS./HR.

Latent Heat From Table 6

953

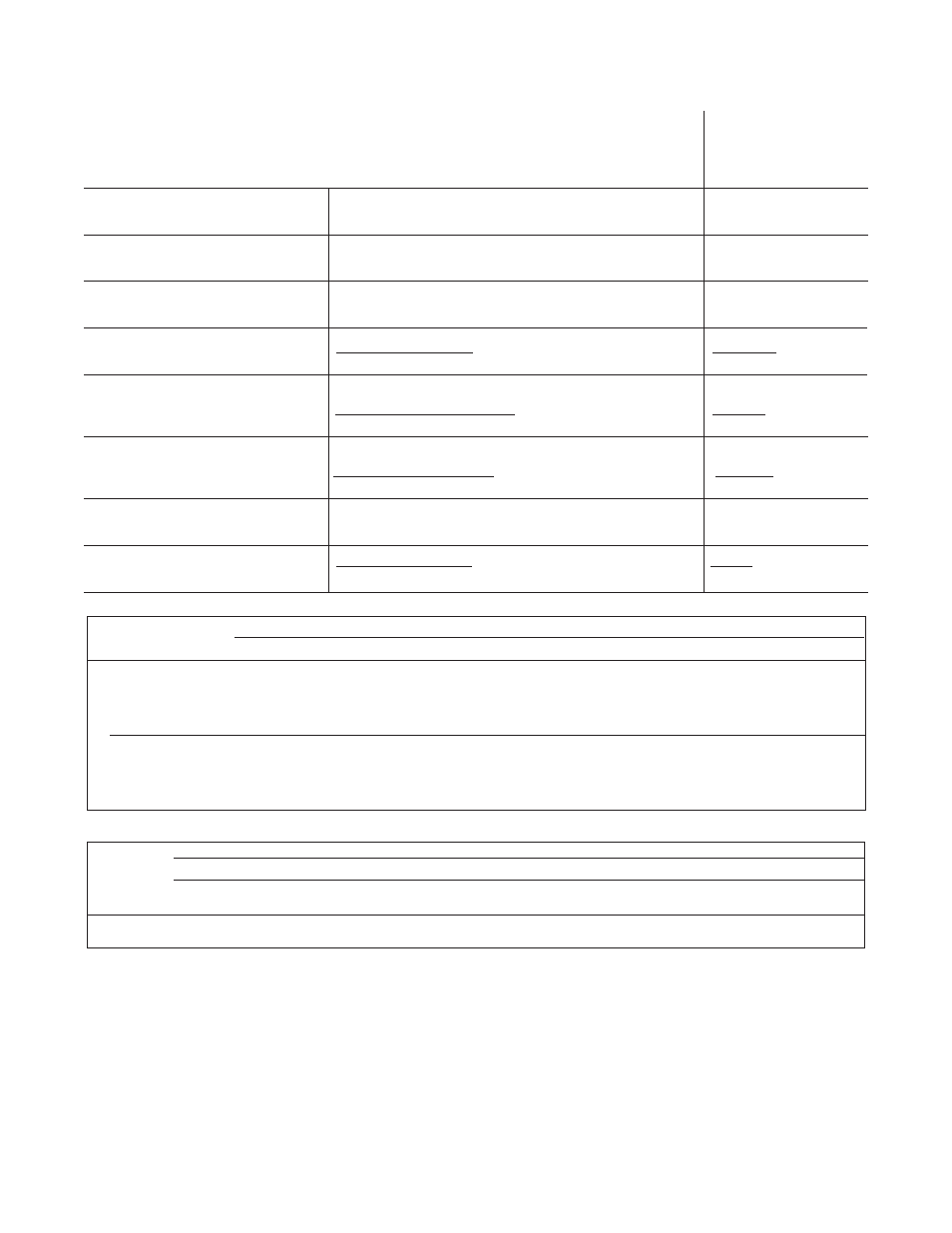

STEAM PRESSURE IN LBS PER SQUARE INCH GAUGE

50 (344.7)

1.67

1.59

1.52

1.45

1.38

1.31

1.24

1.17

STEAM PRESSURE — LBS PER SQUARE INCH (SATURATED)

30° (-1°)

40° (4°)

50° (10°)

60° (16°)

70° (21°)

80° (27°)

90° (32°)

100°

(38°)

40 (275.8)

1.61

1.53

1.46

1.39

1.32

1.25

1.18

1.11

75 (517.1)

1.79

1.71

1.64

1.57

1.49

1.42

1.36

1.29

30 (206.8)

1.53

1.46

1.39

1.32

1.25

1.18

1.11

1.04

20 (137.9)

1.45

1.37

1.30

1.23

1.16

1.09

1.02

0.96

15 (103.4)

1.40

1.32

1.25

1.18

1.11

1.04

0.97

0.90

5 (34.5)

1.27

1.20

1.12

1.05

0.98

0.91

0.85

0.78

2 (13.8)

1.22

1.15

1.07

1.00

0.93

0.86

0.80

0.73

ENTERING AIR

TEMPERATURE °F (°C)

10 (68.9)

1.34

1.27

1.19

1.12

1.05

0.98

0.91

0.85

TABLE 5 — STEAM CORRECTION FACTORS BASED ON 2 LBS. STEAM 60°F EAT

0 (.0)

1.18

1.11

1.03

0.96

0.90

0.83

0.76

0.69

40 (275.8)

286.7

(141.5)

920

(2140)

75 (517.1)

319.9

(159.9)

891

(2072)

50 (344.7)

297.7

(147.6)

912

(2121)

30 (206.8)

274.0

(134.4)

929

(2161)

20 (137.9)

258.8

(126.0)

940

(2186)

15 (103.4)

249.8

(121.0)

946

(2200)

5 (34.5)

227.1

(108.4)

961

(2235)

2 (13.8)

218.5

(103.6)

966

(2247)

10 (68.9)

239.4

(115.2)

953

(2217)

Steam

Temperature-°F (°C)

Latent Heat

of Steam-Btu/lbm (KJ/Kg)

0 (.0)

212.0

(100.0)

970

(2256)

TABLE 6 — PROPERTIES OF SATURATED STEAM

NOTE 1: Ratings apply only to free inlet and discharge

without diffusers.

NOTE 2: All motors are constant speed and operate

at top speed as indicated in motor data. Sizes 40

through 104 can be run at reduced speed with

addition of optional variable speed switch. This

switch is factory-calibrated for low and high speed

ratings, with intermediate speeds infi nitely controllable.

Sizes 164 through 700 operate at constant speed as

indicated in motor data.

NOTE 3: For specifi c motor data refer to motor

specifi cations in Tables 13 and 14.

NOTE 4: To correct for entering air temperatures, use 1°

temperature rise for each foot in mounting height. As an

example, 60°F air is required at work area (5 ft. above

fl oor) units are to be mounted at (20 ft.) above fl oor.

Mounting height (20 ft.) minus work height (5 ft.) equals

differential (15 ft.) or, 15° rise in air temperature at unit

air inlet. Correct for actual inlet air temperature of 75°F

(60°F + 15°F = 75°F EAT) on Table 5.

STEAM CALCULATIONS AND CORRECTION FACTORS

x

x