Sterling VS User Manual

Page 19

19

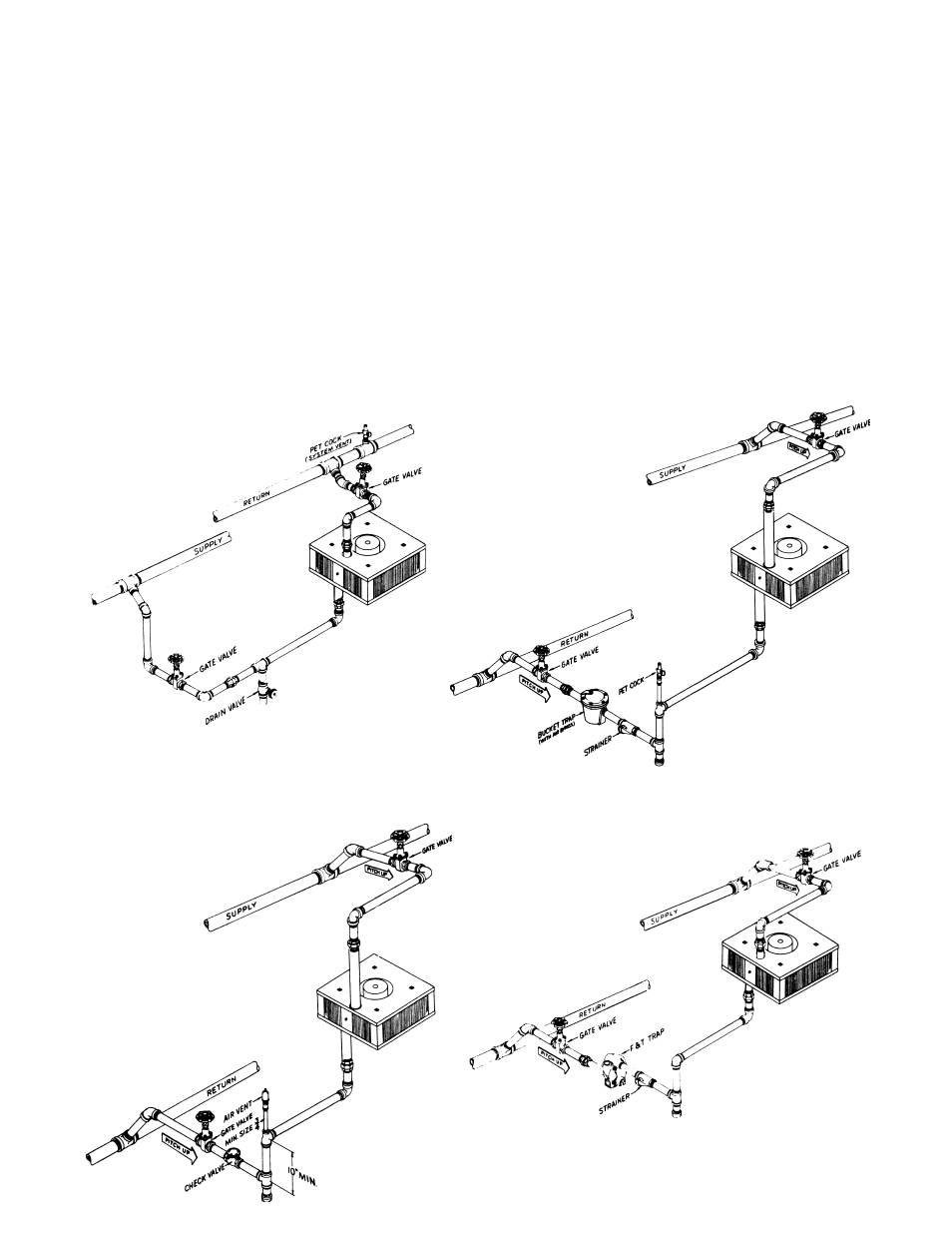

PIPING

To provide proper coil operation, follow all piping

recommendations listed in this manual.

Threaded pipe headers are provided on all Vertical Units

for piping connections. See Figure 5. Connections are

given in Figures 3 and 4 and Tables 1 and 2.

Follow standard practices and codes when installing

the piping. Provide swing joints for expansion purposes,

unions and shut-off valves for servicing purposes and

as illustrated in Figures 6 through 9, valves and traps for

control purposes. Use 45 degree angle run-offs from all

supply and return mains.

Dirt pockets should be the same pipe size as the return

tapping of the unit heater. Also, pipe size in the branch-

off should be the same size as the tapping in the traps.

Beyond the trap, the return lateral pipe should be

increased one size up to the return main.

Properly support all piping to unit! Do not allow piping

to place a strain on the coil or unit. Noise or coil failure

may occur.

It is assumed that the type of system to be used has

been selected by design engineer. The sketches shown

are for different type of steam systems or hot water

systems. For sizing of piping, traps, fi lter, etc., consult

ASHRAE guides of the manufacturer’s literature on

these products.

Figure 6 – Forced Hot Water

Figure 7 – High Pressure Steam

Figure 8 – Low Pressure Steam (Gravity)

Figure 9 – Low Pressure Vapor or Vacuum