Reference junction compensation accuracy, Battery backup – Yokogawa Button Operated MV2000 User Manual

Page 23

3-8

SM MV1000-01E

3.4 Test Procedures

Reference Junction Compensation Accuracy

● Test Procedures

Measure 0°C on all channels, and check that the display is within the reference values

below.

Set all channels to thermocouple type T.

Reference value: ±0.5°C

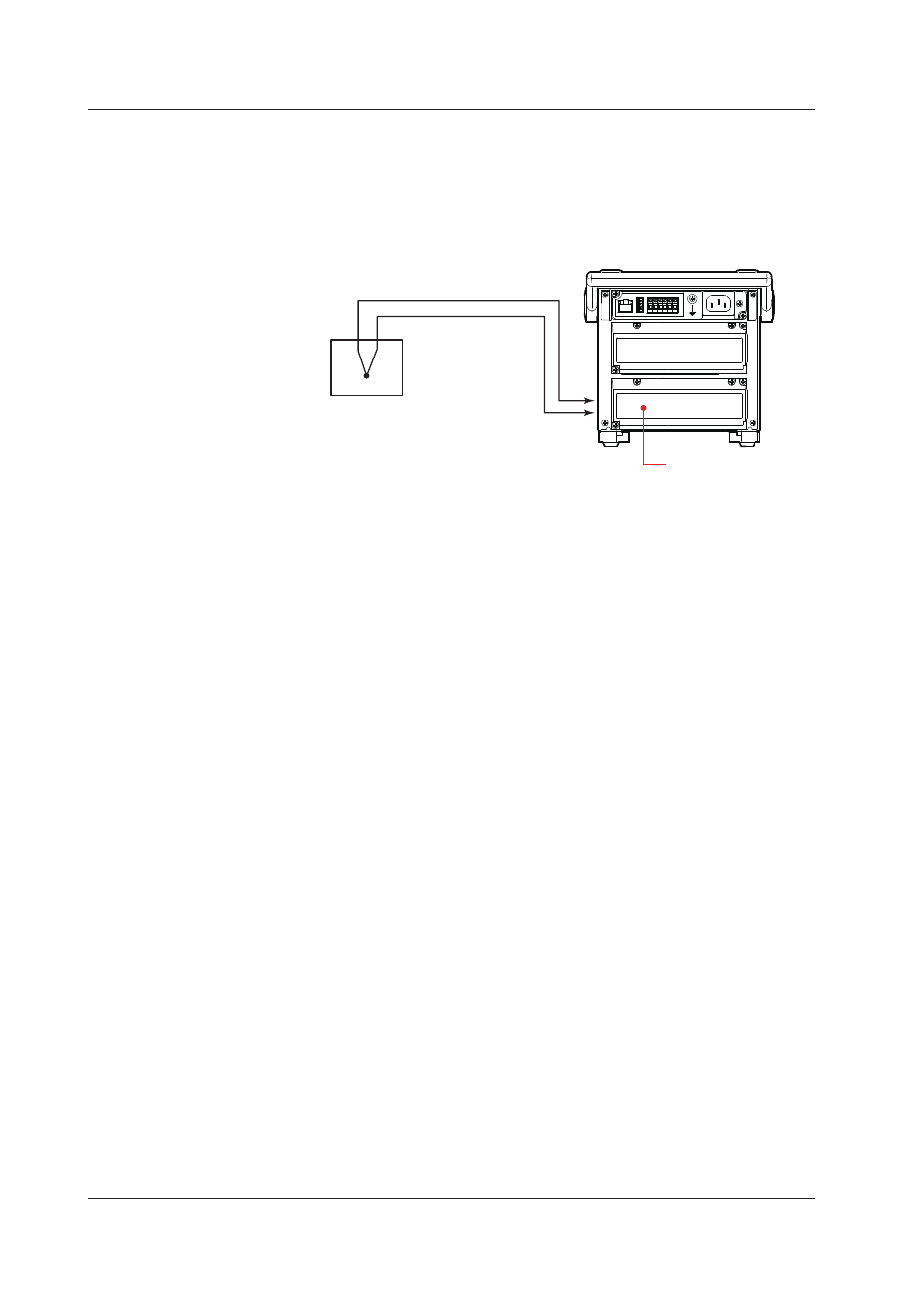

Calibrated thermocouple wires

0°C standard temperature device

(Model: ZC114 from Coper Electronics Co., Ltd.

or equivalent)

+/A

–/B

Input terminal block

• Use a calibrated thermocouple, and wires of 0.5 diameter or less without terminal

tips. Also, be sure to take the level of thermocouple error into consideration during

testing.

• Monitor the 0°C standard temperature device at all times, and confirm that it is

within 0°C ±0.05°C.

• When using a 0°C standard temperature device, ensure that the tip of the

thermocouple floats about 10 mm off the bottom.

• Perform the test in a stable environment. If drafts are present and may influence

the results, position the equipment to avoid them.

• After connecting the thermocouple, allow a warm-up time of 30 minutes or more

before begging measurement.

• Always use terminal covers.

• If the quality is found to be sufficiently stable, perform a test on one representative

channel for each AD converter*.

* Choose any channel number for each A/D from those listed in the “A/D Converter

Configuration” in section 3.4, “Measurement Accuracy.”

Ex.: With the MV1004, set channels 1 and 3 as representative channels.

Battery Backup

● Test Procedures

1.

Set the date and time. Also, set an arbitrary channel to the 20 mV range.

2.

Turn OFF the power switch.

3.

Turn ON the power after approximately one minute, then check that the set date,

time, and range are not initialized.