3 installing the holder, 4 adjusting the protection cage, Fig. 5: protection cage fig. 6: symbol – Yokogawa Pneumatic Retractables RF20H User Manual

Page 9: 4 installation

IM 12B06K05-E-E

9

4. Installation

4.1 Preparing the system

Ensure that

• Sufficient working space for operation of

the retractable holder is available.

• The process is shut off.

• Tank and tubing are pressure-free, empty

and clean.

• Connection flange and process

connection of the retractable holder fit

together.

• The process seal is positioned on the

connection flange.

• Ensure that there is no potentially

explosive atmosphere

4.2 Preparing the holder

The holder must be in the “service”

position!

• The insertion rod (process end) is completely

inserted in the cleaning chamber.

Fig. 4: “service” position

4.3 Installing the holder

Prior to installation, ensure this:

• The system is prepared (chapter 4.1).

• The holder is prepared (chapter 4.2).

How to install the holder:

• Position retractable holder on process

seal.

• Tighten process connection.

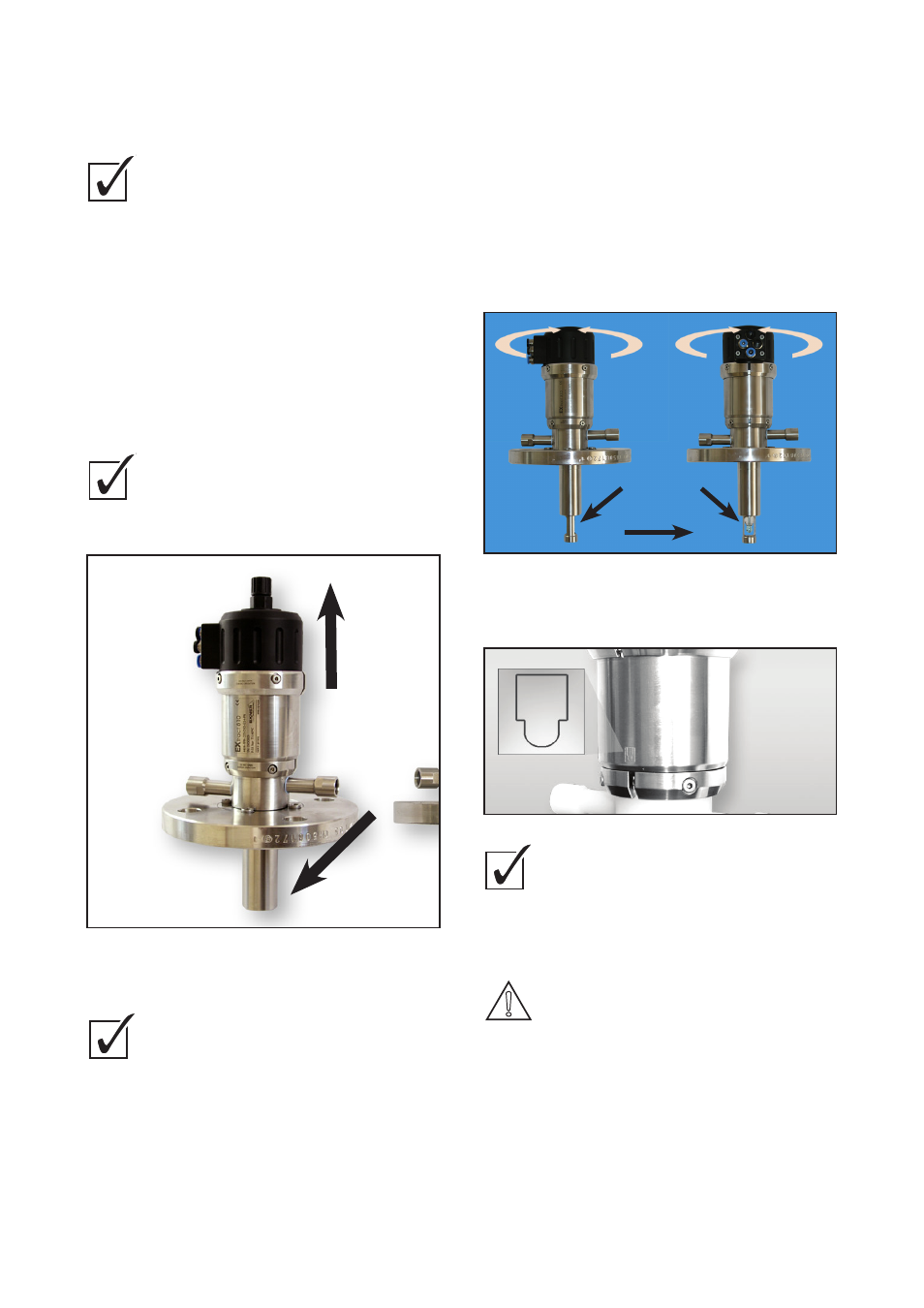

4.4 Adjusting the protection cage

A protection cage is fitted to the lower end of the

insertion rod and can be adjusted with the flow

direction. The symbol on the drive unit cylinder

indicates the position of the opening in the insertion

rod. If the symbol is parallel to the flow direction the

insertion rod is fully flown through. If the symbols

are vertical to the flow the sensor is fully protected

from direct flow. The insertion rod can be adjusted

in any intermediate position.

A) Sensor maximally streamed

B) Sensor minimally streamed

Fig. 5: Protection cage

Fig. 6: Symbol

Ensure that:

• The process is shut off.

• Tank piping and tubing are pressure-free,

empty and clean.

• There is no potentially explosive atmosphere

Leakage of process liquid when

housing cramp is opened during

running process!

Burns or tissue destruction depending on

process liquid property.

• Stop process!

• Tanks and tubing must be pressure-free!

How to adjust the protection cage:

• Loosen screws of lower housing cramp.

• Rotate drive unit and adjust symbol in flow direction.

• Tighten screws of lower housing cramp.

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

A

B

flow direction

4 Installation

14

4.3

Installing the holder

Prior to installation, ensure the following:

"

The system is prepared (chapter 4.1).

"

The holder is prepared (chapter 4.2).

How to install the holder:

1.

Position retractable holder on process seal.

2.

Tighten process connection.

4.4

Adjusting the protection cage

A protection cage is fitted to the lower end of the insertion rod

and can be adjusted with the flow direction. The symbol on the

drive unit cylinder indicates the position of the opening in the

insertion rod. If the symbol is parallel to the flow direction the

insertion rod is fully flown through. If the symbols are vertical to

the flow the sensor is fully protected from direct flow. The

insertion rod can be adjusted in any intermediate position.

A

Sensor maximally streamed

B

Sensor minimally streamed

Fig. 5: Protection cage

Fig. 6: Symbol