6servicing, 1 servicing instructions, 2 checking wetted sealings – Yokogawa Pneumatic Retractables RF20H User Manual

Page 13: Abb. 11: removing the pneumatic tubes, Warning

IM 12B06K05-E-E

13

6. Servicing

6.1 Servicing instructions

• Establish a service plan adapted to your process!

• Leave servicing works to qualified staff.

• Always wear applicable protective clothes when

performing servicing works.

• Do only perform the service works described in

the operation manual!

• Constructional modifications must be agreed with

the manufacturer!

• Tubing and tanks must be pressure-free, empty

and clean before disconnecting the holder from

the process

• Ensure that there is no potentially explosive

atmosphere

6.2 Checking wetted sealings

The retractable holder is fitted with an inspection

window situated between the lower housing

cramps.

Check inspection window for leaking

process liquid on a regular basis.

Fig. 10: Inspection window on lower housing

cramp

Process liquid leaking on the inspection

window!

Risk depending on process liquid property!

• Replace wetted sealings.

• Observe instructions in chapter 6.6!

6.3 Removing the sensor

How to remove the sensor:

1) Move holder to “service” position.

2) Remove sensor cable.

3) Remove PG cable gland.

4) Remove sensor.

Broken glass sensor!

Broken glass may damage the wetted

sealings.

• Check wetted sealings and replace if

necessary.

• Observe instructions in chapter 6.6!

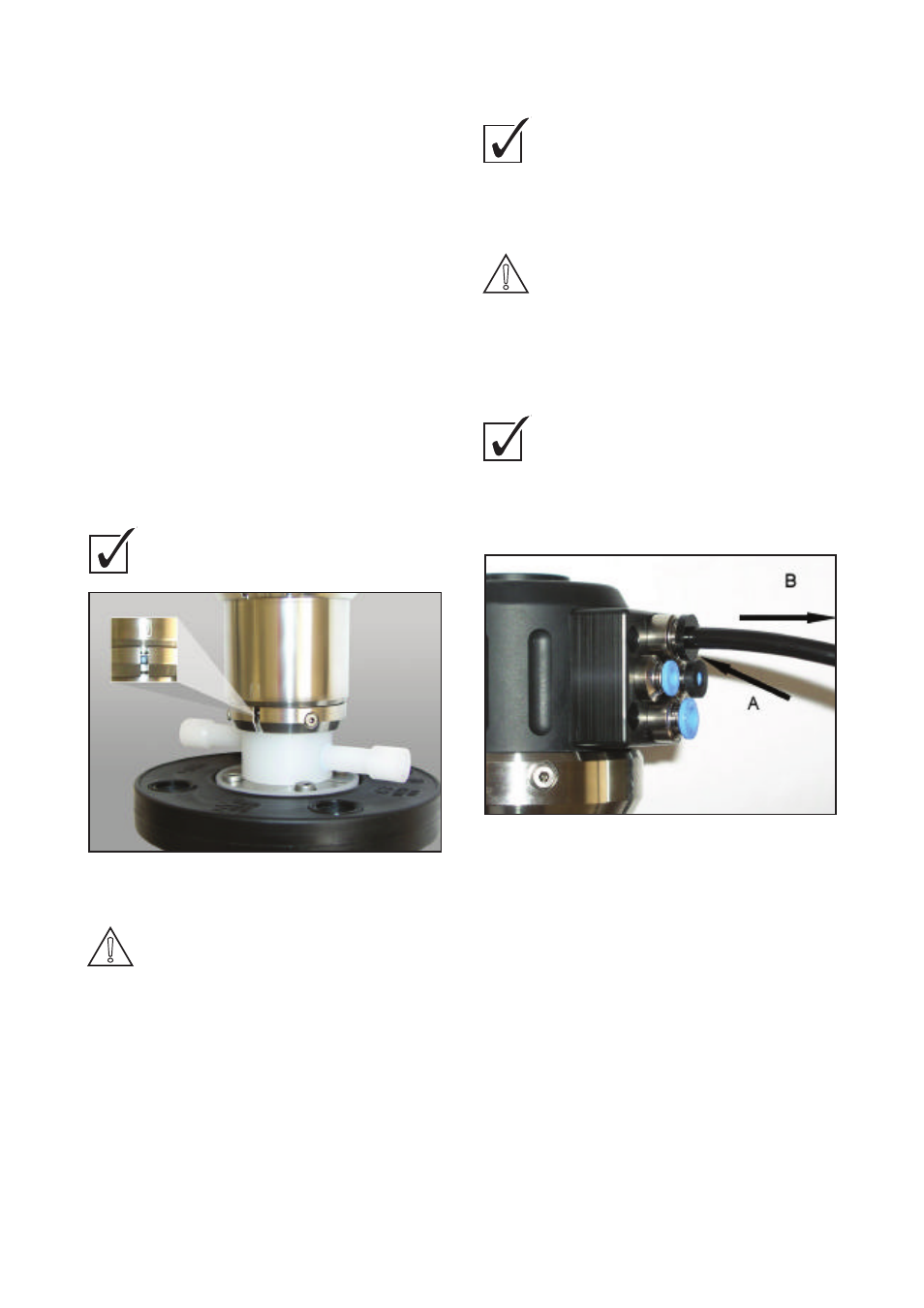

6.4 Removing the pneumatic tubes

How to remove all four pneumatic tubes:

1) Move holder to "service" position.

2) Stop compressed air supply.

3) Press plastic ring “A” on pneumatic

connection.

4) At the same time pull pipe “B”.

Fig. 11: Removing the pneumatic tubes

CAUTION!

DANGER!

WARNING!

23

6

Servicing

6.1

Servicing instructions

"

Establish a service plan adapted to your process!

"

Leave servicing works to qualified staff.

"

Always wear applicable protective clothes when performing

servicing works.

"

Do only perform the service works described in the operation

manual!

"

Constructional modifications must be agreed with the

manufacturer!

"

Tubing and tanks must be pressure-free, empty and clean

before disconnecting the holder from the process

"

Ensure that there is no potentially explosive atmosphere

6.2

Checking wetted sealings

The retractable holder is fitted with an inspection window situated

between the lower housing cramps.

Check inspection window for leaking process liquid on a

regular basis.

Fig. 10: Inspection window on lower housing cramp

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

6 Servicing

25

Abb. 11: Removing the pneumatic tubes

6.5

Removing the cleaning chamber with

process connection

System is under pressure.

Process liquid will leak when holder is disconnected from process

in an inappropriate way.

!

Tubing or tanks must be pressure-free, empty, clean and

without potentially explosive atmosphere.

"

Interrupt the process.

"

Ensure that the system is pressure-free, empty, clean and

without potentially explosive atmosphere.

How to remove the cleaning chamber:

1.

Move holder to “service” position.

2.

Switch off compressed air supply.

Emitted compressed air

can cause material damage or personal injury.

!

Switch off compressed air supply before removing the

pneumatic tubes.

3.

Remove pneumatic tubes (chap. 6.4).

DANGER!

WARNING!