7 removing the insertion rod, 8 installing the insertion rod – Yokogawa Pneumatic Retractables RF20H User Manual

Page 15

IM 12B06K05-E-E

15

4) Remove PTFE scraper “E” on cleaning chamber

5) Remove and replace O ring “F”.

6) Position PTFE scraper “E” on O ring “F”.

Fig. 15: O rings/scraper on cleaning chamber

Scraper ø in [mm] E 19 x 6 x 1

O ring ø in [mm] F 21.89 x 2.62

Remove the PTFE scraper (E) as follows:

Only applicable for RF20H (Extract 810 and 820)

811/812 with separated cleaning chamber:

7) Separated cleaning chamber: Remove and

replace O ring “G”.

Fig. 16: Cleaning chamber 811/821

O ring ø in [mm] G 30 x 1.5

6.7 Removing the insertion rod

System is under pressure.

Process liquid will leak when holder

is disconnected from process in an

inappropriate way.

• Ensure that system is pressure-free before

removing the insertion rod.

• Drain and clean tubing or tanks.

Emitted compressed air

can cause material damage or personal injury.

• Switch off compressed air supply before

removing the pneumatic tubes.

How to remove the insertion rod from

the drive unit:

1) Remove cleaning chamber and process

connection (chap. 6.5).

2) Remove outer O rings on insertion rod

(Fig. 13: “A” and “B”).

3) Remove top housing cramp screws.

4) Remove cylinder “D” from cylinder

extension “A” (Fig. 17)

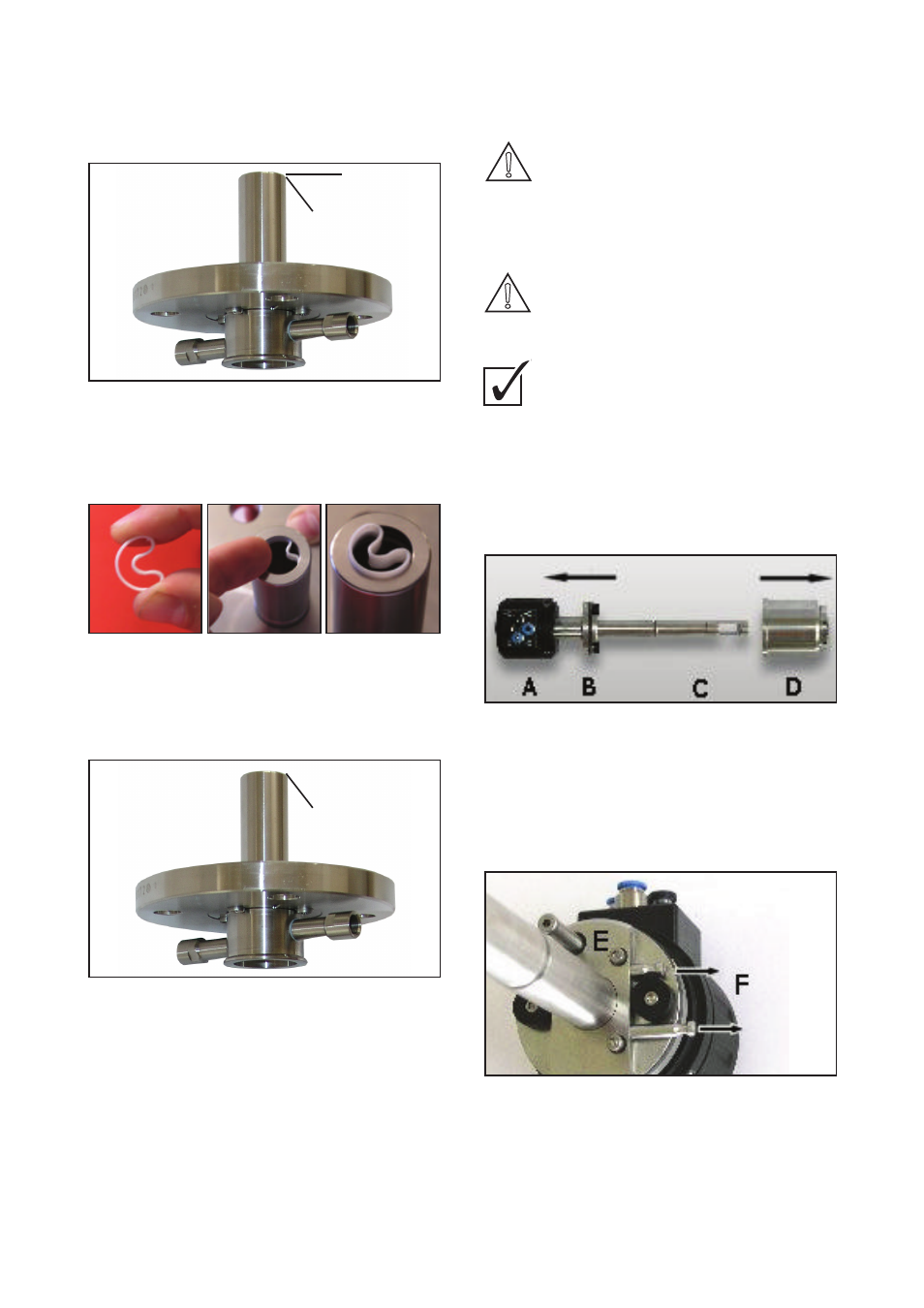

Fig. 17: Removing the cylinder

A Cylinder extension

B Piston

C Insertion rod

D Cylinder

5) Loosen screws “E” and remove pins “F” (Fig. 18).

Fig. 18: Removing the fixing elements

E 2 x M4 x 8

F 2 x pins

6) Remove insertion rod “C” from piston “B”.

F

E

6 Servicing

28

6.

Position PTFE scraper “E” on O ring “F”.

Fig. 15: O rings/scraper on cleaning chamber

Scraper

∅ in [mm]

E 19 x 6 x 1

O ring

∅ in [mm]

F 21.89 x 2.62

Remove the PTFE scraper as follows:

Only applicable for EXtract 811/812 with separated cleaning

chamber:

7.

Separated cleaning chamber: Remove and replace O ring

“G”.

Fig. 16: Cleaning chamber 811/821

O ring

∅ in [mm]

G 30 x 1.5

!!!

6 Servicing

28

6.

Position PTFE scraper “E” on O ring “F”.

Fig. 15: O rings/scraper on cleaning chamber

Scraper

∅ in [mm]

E 19 x 6 x 1

O ring

∅ in [mm]

F 21.89 x 2.62

Remove the PTFE scraper as follows:

Only applicable for EXtract 811/812 with separated cleaning

chamber:

7.

Separated cleaning chamber: Remove and replace O ring

“G”.

Fig. 16: Cleaning chamber 811/821

O ring

∅ in [mm]

G 30 x 1.5

!!!

6 Servicing

28

6.

Position PTFE scraper “E” on O ring “F”.

Fig. 15: O rings/scraper on cleaning chamber

Scraper

∅ in [mm]

E 19 x 6 x 1

O ring

∅ in [mm]

F 21.89 x 2.62

Remove the PTFE scraper as follows:

Only applicable for EXtract 811/812 with separated cleaning

chamber:

7.

Separated cleaning chamber: Remove and replace O ring

“G”.

Fig. 16: Cleaning chamber 811/821

O ring

∅ in [mm]

G 30 x 1.5

!!!

F

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

CAUTION!

DANGER!

WARNING!

6 Servicing

29

6.7

Removing the insertion rod

System is under pressure.

Process liquid will leak when holder is disconnected from process

in an inappropriate way.

!

Ensure that system is pressure-free before removing the

insertion rod.

!

Drain and clean tubing or tanks.

Emitted compressed air

can cause material damage or personal injury.

!

Switch off compressed air supply before removing the

pneumatic tubes.

How to remove the insertion rod from the drive unit:

1.

Remove cleaning chamber and process connection (chap.

6.5).

2.

Remove outer O rings on insertion rod (Fig. 13: “A” and “B”).

3.

Remove top housing cramp screws.

4.

Remove cylinder “D” from cylinder extension “A” (Fig. 17)

Fig. 17: Removing the cylinder

A

Cylinder extension

B

Piston

C

Insertion rod

D

Cylinder

5.

Loosen screws “E” and remove pins “F” (Fig. 18).

DANGER!

WARNING!

6 Servicing

30

Fig. 18: Removing the fixing elements

E

2 x M4 x 8

F

2 x pins

6.

Remove insertion rod “C” from piston “B”.

6.8

Installing the insertion rod

"

The descriptions refer to Fig. 17 and Fig. 18 in chap. 6.7

Removing the insertion rod!

How to assemble the insertion rod and the drive unit:

1.

Adjust slots in insertion rod “C” to piston “B” and put

together.

2.

Insert pins “F”

3.

Tighten screws “E”.

4.

Grease inside wall of cylinder “D”.

5.

Slide cylinder “D” over insertion rod “C”.

6.

Adjust cylinder “D” to cylinder extension “A”.

7.

Squeeze until cylinder snaps into place.

8.

Bring top housing cramp in position and tighten screws.

9.

Insert O rings at insertion rod (Fig. 13: “A” and “B”).