Wiring, 1 notes on wiring, 2 loop construction – Yokogawa YTA320 User Manual

Page 24: 3 cable selection, 1 input signal cable selection, Notes on wiring, Loop construction, Cable selection - 5.3.1, Input signal cable selection -1

<5. Wiring>

5-

IM 01C50B01-01E

5. Wiring

5. Notes on Wiring

IMPORTANT

• Apply a waterproofing sealant to the threads

of the connection port. (It is recommended

that you use non-hardening sealant made of

silicon resin for waterproofing.)

• Lay wiring as far away as possible from

electrical noise sources such as large

transformers, motors and power supplies.

• Remove the wiring connection dust-caps

before wiring.

• To prevent electrical noise, the signal cable

and the power cable must not be housed in

the same conduit.

• The terminal box cover is locked by an Allen

head bolt (a shrouding bolt) on ATEX, IECEx

and TIIS flameproof type transmitters.

When the shrouding bolt is driven clockwise

by an Allen wrench, it is going in and cover

lock is released, and then the cove can

be opened by hands. See Subsection 6.3

“Disassembly and Reassembly” for details.

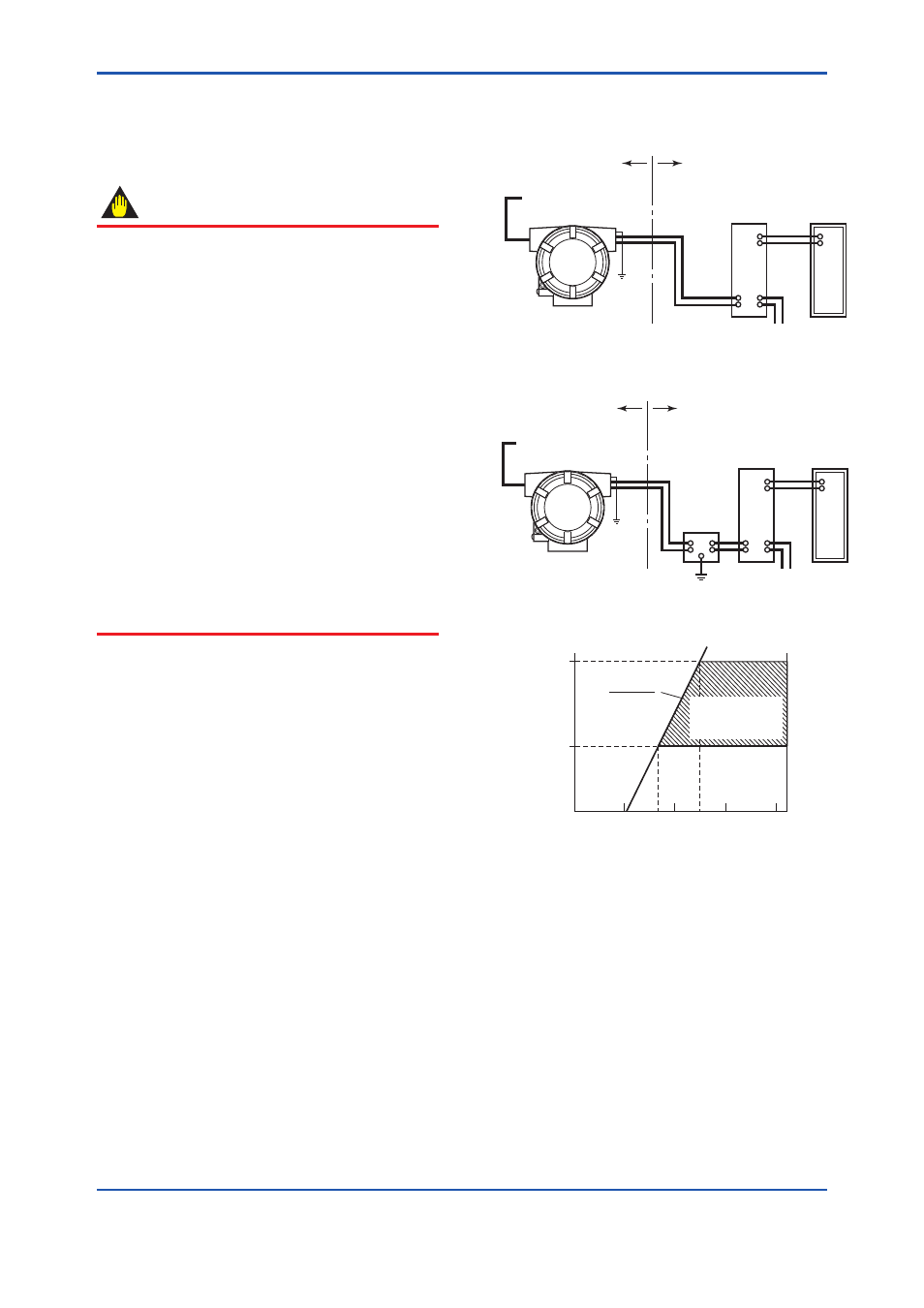

5.2 Loop Construction

The YTA is a two-wire temperature transmitter that

uses the output power supply wiring and signal

wiring alternately.

The transmission loop requires DC power. Connect

the transmitter with the distributor as shown in

Figure 5.1 or Figure 5.2.

For the transmission loop, the load resistance of

the distributor or other instrument to be installed in

the loop and the lead wire must be within the range

shown in Figure 5.3.

For details of communication requirements, refer to

the additional reference materials, IM 01C50T03-

01E “YTA Series BRAIN Communication”,

and IM 01C50T01-01E “YTA Series HART

Communication”.

F0501.ai

+

Output signal

–

Distributor

(power supply unit)

Receiver

Input signal

(thermocouple,

RTD, mV, etc.)

Figure 5.

Loop Construction (for General-use

Type and Flameproof Type)

F0502.ai

+

Output signal

–

Distributor

(power supply unit) Receiver

Safety

barrier

Input signal

(thermocouple,

RTD, mV, etc.)

Figure 5.2

Loop Construction (for Intrinsically

Safe Type)

600

250

10.5 16.4

24.7

42

Power supply voltage E (V DC)

R= 0.0236

E–10.5

F0503.ai

External

load

resistance

R

(Ω)

Communication

applicable range

BRAIN and HART

Figure 5.3

Relation between Power Supply

Voltage and Load Resistance

Note: For intrinsic safe explosion-proof type units, the internal

resistance of the safety barrier is also included in the load

resistance.

5.3 Cable Selection

5.3. Input signal Cable Selection

A dedicated cable is used for connection between

the temperature sensor and the temperature

transmitter.