Integral type rcct3, option code – Yokogawa RotaMASS 3-Series User Manual

Page 72

IM 01R04B08-00E-E 1st edition February 15, 2012 -00

All Rights Reserved. Copyright © 2012, Rota Yokogawa

<10. GENERAL SPECIFICATIONS>

10-2

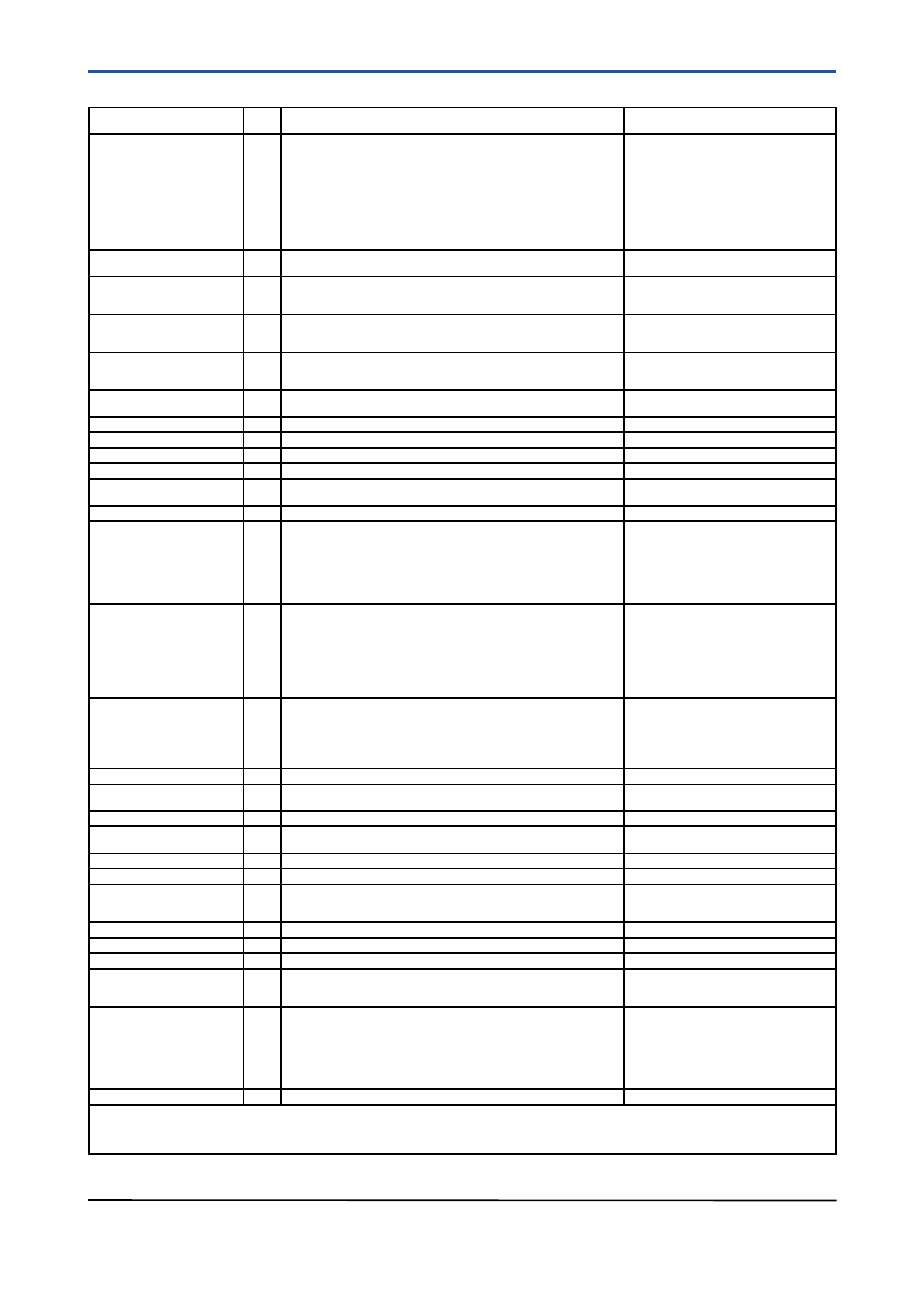

Integral Type RCCT3, Option Code :

Options

Option

code

Description

Restrictions

Hazardous Area Approvals

/KF1

/KF2

/FF1

/FF2

/EF1

/EF2

/UF1

/UF2

ATEX Flame proof converter + Intrinsic safe detector

ATEX Flame proof converter + Intrinsic safe detector + Intrinsic safe outputs

FM approval for USA+Canada, Flame proof converter + Intrinsic safe detector + 2

active analog outputs + 2 passive pulse outputs + 1 status input

FM approval for USA+Canada, Flame proof converter + Intrinsic safe detector +

1 passive analog output + 1 passive pulse output

IECEx Flame proof converter + Intrinsic safe detector

IECEx Flame proof converter + Intrinsic safe detector + Intrinsic safe outputs

INMETRO Flame proof converter + Intrinsic safe detector

INMETRO Flame proof converter + Intrinsic safe detector + Intrinsic safe outputs

with /HP for gas group IIB

with /HP for gas group IIB

only with cable conduit ´A´; with /HP not for

groups A and B

only with cable conduit ´A´; with /HP not for

groups A and B

with /HP for gas group IIB

with /HP for gas group IIB

with /HP for gas group IIB

with /HP for gas group IIB

Custody Transfer Measurement

acc. OIML R 117-1

/Q01

European MID Approval (fluids other than water) (refer to GS 01R04B07-00E)

GOST

/QR1

/QR2

/QR3

Primary Calibration and Test Confirmation valid in Russia

Primary Calibration and Test Confirmation valid in Kazakhstan

Primary Calibration and Test Confirmation valid in Uzbekistan

see page 9

see page 9

see page 9

Dual Seal Approval

/DS

/RD

Dual Seal approval (conform with ANSI/ISA-12.27.01)

Rupture disk

only with /FF1; not with process connection A5;

not wit RCCT39/XR, preferable with /GA, manda-

tory if /DS+/GA is selected

High Driving Power

/HP

High Driving Power

not for RCCT34, recommended for RCCT36

to 39, strongly recommended for RCCT39/IR,

mandatory for RCCT39/XR

Communication

/FB

/MB1

Digital communication Foundation Fieldbus protocol (refer to GS 01R04B05-00E)

Modbus communication protocol for selected parameters and values

not with /FB, /Q01, /KF2, /EF2, /UF2, /FF2, /AP

Active Pulse Output

/AP

One active pulse output

not with /KF2, /EF2, /UF2, /NM

NAMUR Switch

/NM

One pulse output acc. to EN 60947-5-6 (NAMUR)

not with /AP

Tag Number

/BG

With customer specified tag number on name plate

max. 16 digits

HART Tag Number (Software Tag)

/BT1

With customer specified tag number for HART communication in converter

8 digits for tag, 22 digits for long tag

Flange Facing

/DN

/RJ

Flange with safety grooves acc. to EN 1092-1 form D

Ring Type Joint Flanges

only for D2 to D6; not HC

only for A3, A4, A5; not HC

Gas Measurement

/GA

Gas measurement, special factory adjustments and settings

to be conform with ANSI/ISA-12.27.01 select /RD

Special Calibration

/K2

2)

/K4 /

K5

2)

/K6

Custom 5 pts mass-/volume-flow calibration using water with factory certificate

(traceable to German national standards)

Density adjustment + thermal treatment; (accuracy: 0.001 g/cm³)

Custom 10 pts mass-/volume-flow calibration using water with DKD certificate

(according EN-17025:2005)

Density calibration with 3 different fluids incl. individual temperature compensation

with certificate (accuracy: 0.0005 g/cm³)

only RCCT34 to 39; not with /GA

only RCCT34 to 39; not with /GA

Certificates

/P2

/P3

/P6

/P8

/H1

/WP

Certificate of compliance with the order acc. to EN 10204:2004 -2.1

As /P2 + Test report acc. to EN 10204: 2004 -2.2 (QIC)

Material certificate acc. to EN 10204: 2004 -3.1

Pressure test report measuring system

Oil and fat free for wetted surface acc. to ASTM G93-03 level C

WPS acc. DIN EN ISO 15609-1 (Welding Procedure Specification)

WPQR acc. DIN EN ISO 15614-1 (Welder Performance Qualification Record)

WQC acc. DIN EN 287-1 (Welder Qualification Certificate)

only for butt weld between process connection

and flow divider; not for material HC

Sanitary Type

/SF1

/SF2

/SA

/SE

Surface roughness Ra = 0.8 µm

As /SF1 + Test report roughness of wetted parts

As /SF2 + 3A- declaration of conformity and 3A- mark

As /SF2 + EHEDG certificate

not RCCT39/XR; only process connections S2,

S4, S8;

see also restrictions in table 11

not with process connection S2

not with process connection S2

Customer Presetting

/PS

Presetting sheet with customer data

has to be issued with the order

Housing Pressure Test

/J1

Rupture pressure proof test and certificate:

60 bar (RCCT34, RCCT36), 40 bar (RCCT38), 10 bar (RCCT39, RCCT39/IR)

not for RCCT39/XR

X-Ray Examination

/RT

X-ray examination of flange welding

RCCT34 with /K4 or /K6 only one-sided

PMI Examination

/PM6

PAMI test (6 test points: process connection inlet + outlet, measuring tubes, flow

divider inlet + outlet)

3)

Dye Penetration Test

/PT

Dye penetration test of flange welding

Epoxy Coating

/X1

Epoxy coating of converter housing

Concentration Measurement

4)

/CST

/Cxx

Standard concentration measurement

Advanced concentration measurement, details see table „Advanced Concentration

Measurement Options“

Delivery to Japan

/PJ

For meters which are delivered to Japan, with SI-unit preset

Delivery to Korea

/KC

With KC-mark for Korea

Cable glands

/AD2

2 pcs ANSI 1/2“ NPT / G1/2 adapter

only with cable conduit ´A´

Instruction Manuals

/IEn

/IDn

/IFn

Quantity of instruction manuals in English

Quantity of instruction manuals in German

Quantity of instruction manuals in French

n = 1 to 3 selectable

5)

n = 1 to 3 selectable

5)

n = 1 to 3 selectable

5)

Quick Delivery

/QD

Delivery within 24 hours from factory

not RCCT39/IR, RCCT39/XR,

not with process connection size 23, 12,

only with process connection rating A1, A2, D4,

only material SL,

only for options /KF1, /FF1, /EF1, /UF1, /HP, /AP,

/NM, /NA, /BG, /P2, /P3, /P8, /CST, /Cxx, /IEn, /

IDN , /IFn

Special order

/Z

Special design must be specification an extra sheet

2)

Calibration order sheet must be delivered with the order. This is available on the Flow Center Page at Coriolis/RCCx3/Technical Information.

3)

Measuring tube PAMI test is performed per delivery batch.

4)

For detailed information please see TI 01R04B04-04E-E. Concentration measurement is recommended with option /K6.

5)

If no instruction manual is selected, only a DVD with instruction manuals is shipped with the instrument. More than 3 manuals of one language on request.