Hazardous area specifications, Controller (option /r1 and r3), Metrological regulation in cis (gost) – Yokogawa RAKD User Manual

Page 38: Rakd “non incendive” (option /kn1)

IM 01R01B30-00E-E 5th edition January 01, 2013 -00

<7. TECHNICAL DATA>

7-8

All Rights Reserved. Copyright © 2003, Rota Yokogawa

HAZARDOUS AREA SPECIFICATIONS

RAKD with ATEX- certification “intrinsic safe”

(option /KS1)

Certificate :

KEMA 00ATEX 1037X

Output signal :

4–20 mA / Pulse output / Limit switches

Explosion proof :

Ex ia IIC T6 ... T4 Gb

Entity parameter :

Table 7-6

Analog

output

Pulse

output

Limit

switch

type 2

/K1-/K3

Limit

switch

type 3

/K1-/K3

Limit

switch

type 2

/K6-/K8

Limit

switch

type 3

/K6-/K8

Ui [V]

30

16

16

16

16

16

Ii[ mA]

100

20

25

52

25

52

Pi [mW]

750

64

64

169

64

169

Li [mH]

0.73

0

0.15

0.15

0.1

0.1

Ci [nF]

2.4

0

150

150

30

30

Temperature specification :

Table 7-7

Configura-

tion

Max.

ambient

temperature

Max.

process tem-

perature

Temperature

class

Transmitter

4-20mA /

Pulse

65°C

65°C

T6

50°C

80°C

45°C

100°C

T5

38°C

135°C

T4

Limit

switch(es)

type 2

65°C

65°C

T6

80°C

80°C

T5

59°C

100°C

100°C

100°C

T4

73°C

135°C

Limit

switch(es)

type 3

24°C

65°C

T6

37°C

80°C

T5

34°C

100°C

57°C

80°C

T4

54°C

100°C

48°C

135°C

For the configuration where a transmitter is combined with

limit switches, the temperature class is determined by the

most restrictive combinations of maximum ambient temperature

and maximum process temperature.

Description of limit switch type 2 and 3 see ATEX certificates

from Pepperl & Fuchs:

- PTB 99 ATEX 2219X ( SC2-NO) for /K1 to /K3

- PTB 00 ATEX 2049X (SJ2-S.N) for /K6 to /K10

RAKD “non incendive” (option /KN1)

Type “n” (non incendive) acc. EN 60079-15.

Explosion proof :

Ex nL IIC T6 protection „nL”; group II ; category 3G

Dust proof :

Ex II 3D; group II ; category 3D

Max. surface temperature : 80°C

Entity parameter :

see table 7-6

Temperature specification :

see table 7-7

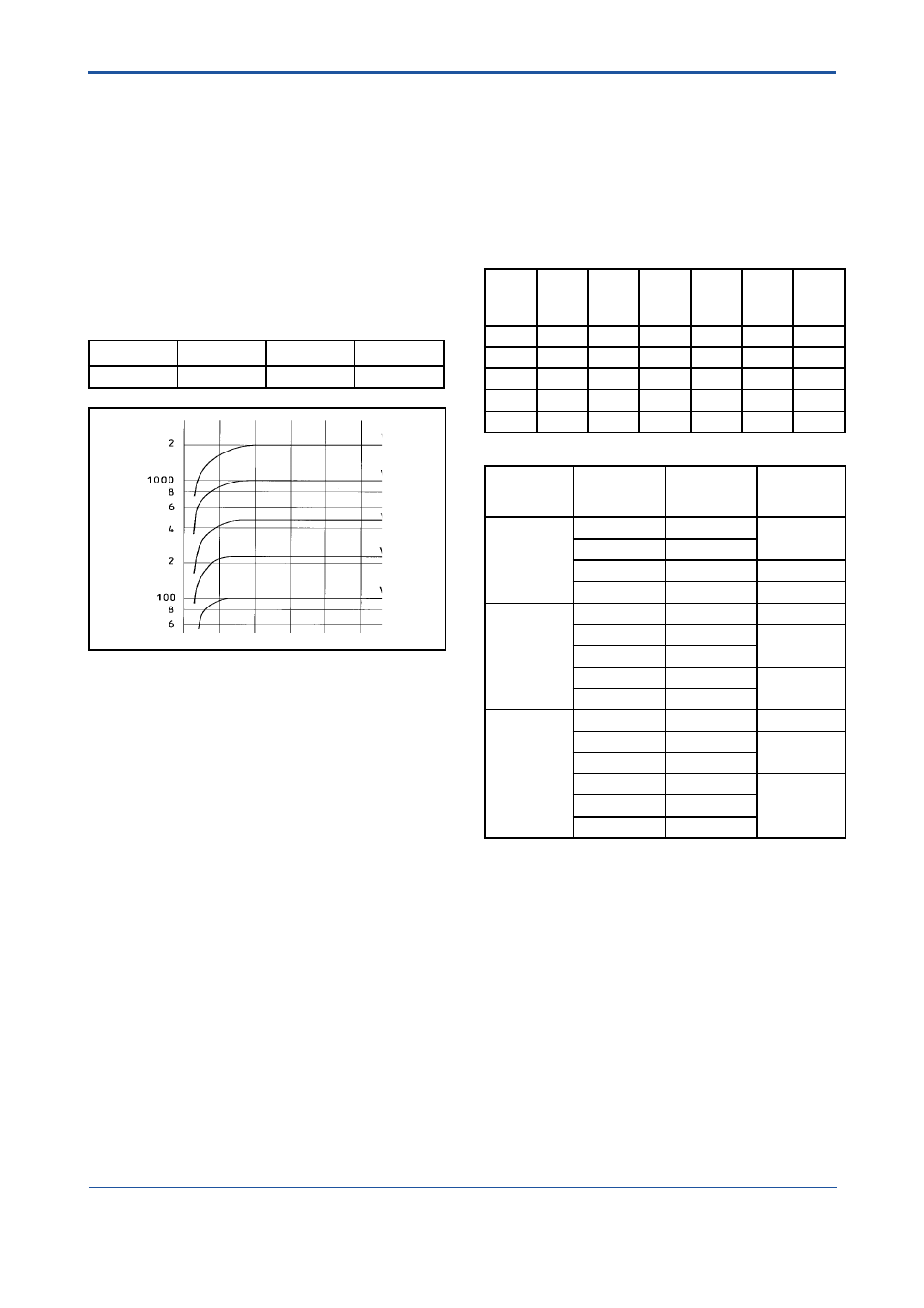

CONTROLLER (Option /R1 and R3)

Differential pressure controller for a constant flow at

fluctuations of the process pressure.

These are no valves to reduce the pressure.

-

Controller /R1 for liquids with variable inlet or

outlet pressure and for gases with variable inlet pressure

and constant back pressure.

-

Controller /R3 for gases with fluctuations of the back pressure.

Max. liquid flow

: 100 l/h

Max. gas flow

: 3250 l/h

Max. pressure

: 25 bar

Recommended differential pressure

: >400 mbar

Temperature range : -25°C to + 80°C

Materials :

Table 7-5

Housing

Diaphragm

Springs

/R1 / /R3

CrNi-Steel

PTFE

CrNi-Steel

F2.EPS

l/h air at 20°C ; 1.013 bar abs.

Inlet pressure

Fig. 7-1 Diagram controller characteristic

COMPLIANCE WITH IEC 61508

RAKD with local indicator and standard or fail safe limit

switches (RAKD[][]-[][]SS-[][][][][]-T[][]NNN/K1…K10):

Suitable for application in safety functions up to and including

SIL2.

RAKD with valve and controller with local indicator and

standard or fail safe limit switches

(RAKD[][]-[][]SS-[][]V[][]-T[][]NNN/R[]/K1…K10):

Suitable for application in safety functions up to and including

SIL1.

Reliability data available on request in FMEDA report.

COMPLIANCE WITH ISO 13849

For Safety Metrics acc. to ISO 13849-2 please refer to the

FMEDA report.

METROLOGICAL REGULATION IN CIS (GOST)

RAKD has “Pattern Approval Certificate of Measuring

Instruments” and is registered as a measuring instrument in

Russia, Kazakhstan, Uzbekistan, Belarus and Ukraine.

The calibration laboratory of Rota Yokogawa is approved by

Federal Agency on Technical Regulating and Metrology in

Russia and other Metrological Organizations in CIS countries

to issue primary calibration confirmations for RAKD, option

/QR[].

Furthermore RAKD is RTN (GGTN) approved for installation

in hazardous areas.

For export to CIS countries please contact your Yokogawa

representative.