4 dimensions, Model eja438w [style: s2 – Yokogawa EJA438 User Manual

Page 59

IM 1C22J1-01E

9-7

9. GENERAL SPECIFICATIONS

9.4

Dimensions

᭹

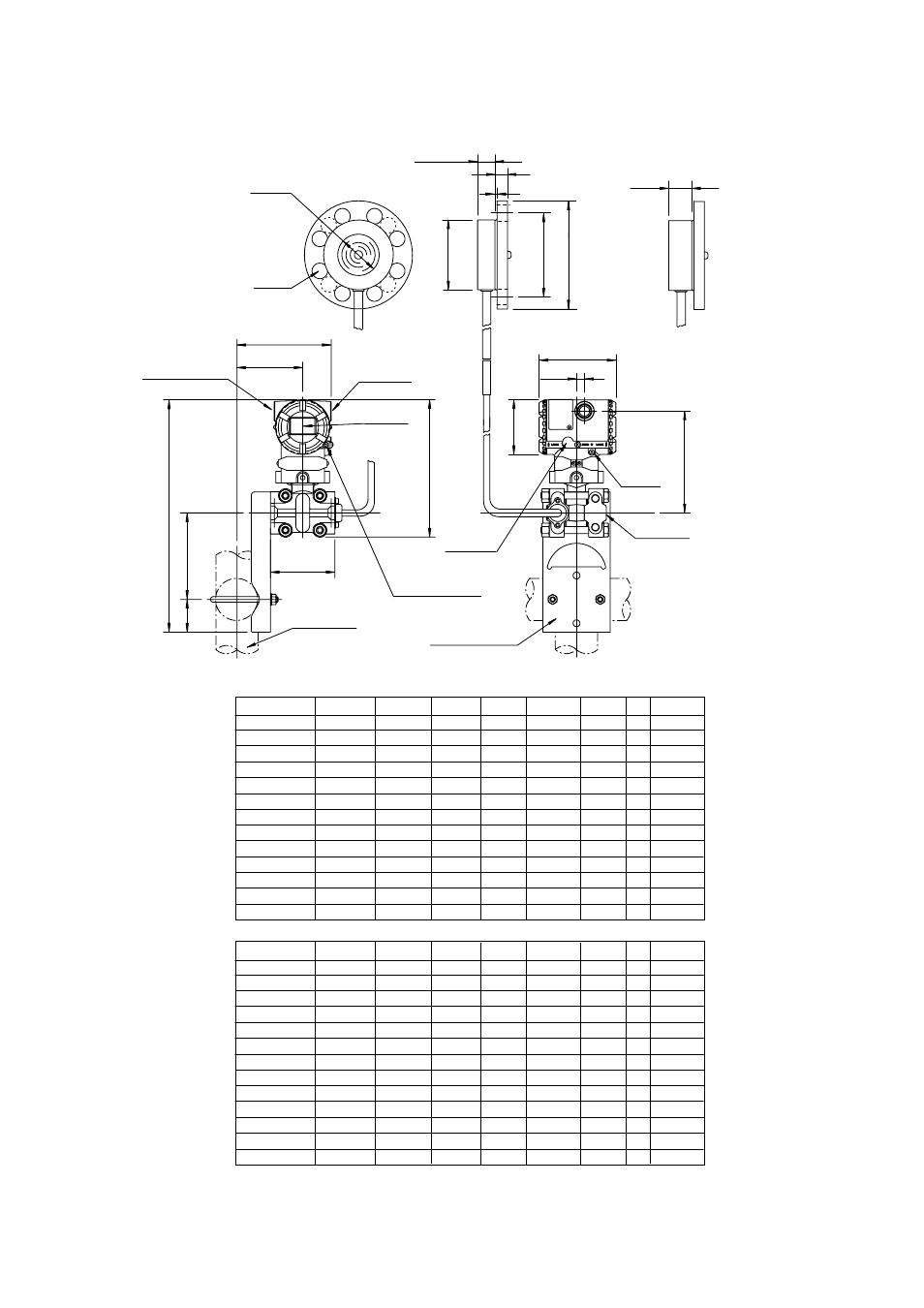

Model EJA438W [Style: S2]

34

(1.34)

Wetted parts material

code U (Titanium)

333(13.11)

140(5.51)

94(3.70)

197(7.76)

92

(3.62)

124

(4.88)

47

(1.85)

External indicator

conduit connection

(Optional)

2-inch pipe

(O.D. 60.5mm)

Internal

indicator

(Optional)

Conduit

connection

Clamps (Only for JIS

Flameproof type)

146(5.75)

12

(0.47)

110 (4.33)

ø78

(3.07)

Zero

adjustment

Ground

terminal

Mounting bracket

(Flat-type, Optional)

Terminal

side

Open to

atmosphere

(ø5mm)

n-øh

25 (0.98)

t

øg

f

øC

øD

ød*

1

Flange Rating

JIS 10K

JIS 20K

JIS 40K

JIS 63K

ANSI Class 150

ANSI Class 300

ANSI Class 600

JPI Class 150

JPI Class 300

JPI Class 600

DIN PN 10/16

DIN PN 25/40

DIN PN 64

øD

155(6.10)

155(6.10)

165(6.50)

185(7.28)

152.4(6.00)

165.1(6.50)

165.1(6.50)

152(6.10)

165(6.50)

165(6.50)

165(6.50)

165(6.50)

180(7.09)

t

16(0.63)

18(0.71)

26(1.02)

34(1.34)

19.1(0.75)

22.4(0.88)

31.8(1.25)

19.5(0.77)

22.5(0.89)

31.9(1.26)

18(0.71)

20(0.78)

26(1.02)

øC

120(4.72)

120(4.72)

130(5.12)

145(5.12)

120.7(4.75)

127.0(5.00)

127.0(5.00)

120.6(4.75)

127.0(5.00)

127.0(5.00)

125(4.92)

125(4.92)

135(5.31)

n

4

8

8

8

4

8

8

4

8

8

4

4

4

øh

19(0.75)

19(0.75)

19(0.75)

23(0.91)

19.1(0.75)

19.1(0.75)

19.1(0.75)

19(0.75)

19(0.75)

19(0.75)

18(0.71)

18(0.71)

22(0.87)

øg

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

100(3.94)

ød

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

61(2.40)

f *

0

0

0

0

1.6(0.06)

1.6(0.06)

6.4(0.25)

1.6(0.06)

1.6(0.06)

6.4(0.25)

0

0

0

Process flange size: 2-inch(50 mm)

Flange Rating

JIS 10K

JIS 20K

JIS 40K

JIS 63K

ANSI Class 150

ANSI Class 300

ANSI Class 600

JPI Class 150

JPI Class 300

JPI Class 600

DIN PN 10/16

DIN PN 25/40

DIN PN 64

Process flange size: 3-inch(80mm)

øD

185(7.28)

200(7.87)

210(8.27)

230(9.06)

190.5(7.50)

209.6(8.25)

209.6(8.25)

190(7.48)

210(8.27)

210(8.27)

200(7.78)

200(7.78)

215(8.46)

t

18(0.71)

22(0.87)

32(1.26)

40(1.57)

23.9(0.94)

28.5(1.12)

31.8(1.25)

24(0.94)

28.5(1.12)

38.4(1.51)

20(0.79)

24(0.94)

28(1.10)

øC

150(5.91)

160(6.30)

170(6.69)

185(7.28)

152.4(6)

168.1(6.62)

168.1(6.62)

152.4(6)

168.1(6.62)

168.1(6.62)

160(6.30)

160(6.30)

170(6.69)

n

8

8

8

8

4

8

8

4

8

8

8

8

8

øh

19(0.75)

23(0.91)

23(0.91)

25(0.98)

19.1(0.75)

22.4(0.88)

22.4(0.88)

19(0.75)

22(0.87)

22(0.87)

18(0.71)

18(0.71)

22(0.87)

øg

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

130(5.12)

ød

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

90(3.54)

f *

0

0

0

0

1.6(0.06)

1.6(0.06)

6.4(0.25)

1.6(0.06)

1.6(0.06)

6.4(0.25)

0

0

0

* In case where process flange material is JIS S25C, value of f is 0.

Unit: mm(approx. inch)

F0902.EPS

*1: Indicates inside diameter of gasket contact surface.