2 when you cannot obtain low range value, 3 starting operation, 4 shutting down operation – Yokogawa EJA438 User Manual

Page 28

IM 1C22J1-01E

6-3

6. OPERATION

6.2.2 When you cannot obtain Low Range

Value from actual measured value

of 0%;

Convert the actual measured value obtained by a digital

manometer or a glass gauge into %.

[Example]

The measuring range of 50 to 250 kPa; the actual

measured value of 130 kPa.

Actual measured value=

ϫ

100=40.0%

130–50

250–50

Using the Transmitter Zero-Adjustment

Screw

Turn the screw to match the output signal to the actual

measured value in %.

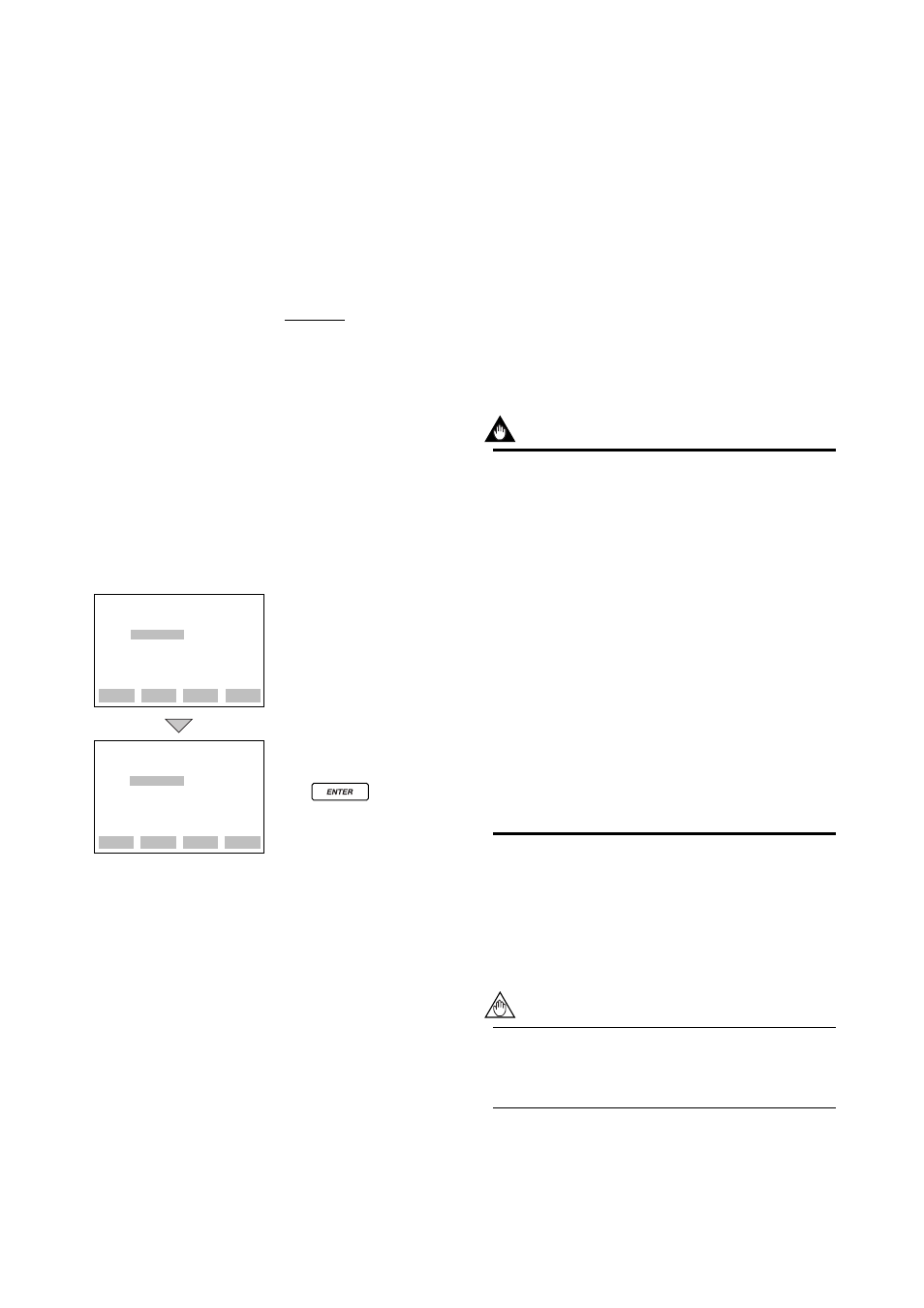

Using the BT200

Select the parameter

J10: ZERO ADJ.

Change the

set point (%) displayed for the parameter to the actual

measured value (%), and press the

ENTER

key twice.

See Subsection 7.3.3 (11) for operation details.

Change setting to the actually

measured value (40.0%).

Press

key twice

for 40% output 10.4 mA DC.

SET

J10:ZERO ADJ

–0.0 %

+ 040.0

CLR

ESC

F0606.EPS

A display at J10

SET

J10:ZERO ADJ

–0.0 %

+ 000.0

CLR

ESC

6.3 Starting Operation

After completing the zero point adjustment, use the

procedure below to start operation.

1) Confirm the operating status.

There will be cases in which the output signal

exhibits wide fluctuations (hunting) due to periodic

variation in the process pressure. In such cases,

BT200 operation can dampen the transmitter

output signal. Confirm the hunting using a receiv-

ing instrument or the integral indicator, and set the

optimum damping time constant. See Subsection

7.3.2 (3), “Damping Time Constant Setup.”

2) After confirming the operating status, perform the

following.

IMPORTANT

• Remove the BT200 from the terminal box, and

confirm that none of the terminal screws are

loosened.

• Close the terminal box cover and the amplifier

cover. Screw each cover in tightly until it will

not turn further.

• Two covers are required to be locked on the

CENELEC, SAA, and JIS Flameproof type

transmitters. An Allen head bolts (shrouding

bolts) are provided under edge of the each

cover for locking. When a shrouding bolts are

driven counterclockwise by an Allen wrench, it

is coming out and locks up a cover. (See page

8-4)

After locking, the covers shoud be confirmed

not to be opened.

• Tighten the zero-adjustment cover mounting

screw to fix the cover in position.

6.4 Shutting Down Operation

Turn off the power.

NOTE

Whenever shutting down the transmitter for a

long period, detach the transmitter (diaphragm

seals) from the tank.