4 affixing the teflon film, 5 rotating transmitter section – Yokogawa EJA438 User Manual

Page 21

IM 1C22J1-01E

4-3

4. INSTALLATION

4.4 Affixing the Teflon Film

The FEP Teflon option includes a teflon film and

fluorinated oil.

Before mounting the diaphragm seal to the process

flange, affix the teflon film as follows :

IMPORTANT

(1) Position the diaphragm seal so that the

diaphragm is in a upward position.

(2) Pour the fluorinated oil on the diaphragm and

gasket area covering it completely and

evenly. Be careful not to scratch the dia-

phragm or change the its shape.

(3) Affix the teflon film over the diaphragm and

gasket area.

(4) Next, carefully inspect the cover and try to

identify any entrapped air between the

diaphragm and the teflon film. The air must

be removed to ensure accuracy. If air

pockets are present, use your fingers to

remove the air by starting at the center of the

diaphragm and work your way out.

(5) Place the gasket with the teflon film and affix

to the process flange.

Teflon film

Diaphragm

Fluorinated oil

[PART No.: F9145YN]

Gasket area

Diaphragm seal

PART No.

F9347XA

F9347YA

Process flange size

For 3inch (80 mm)

For 2inch (50 mm)

F0405.EPS

Figure 4.4.1 Affixing the Teflon Film

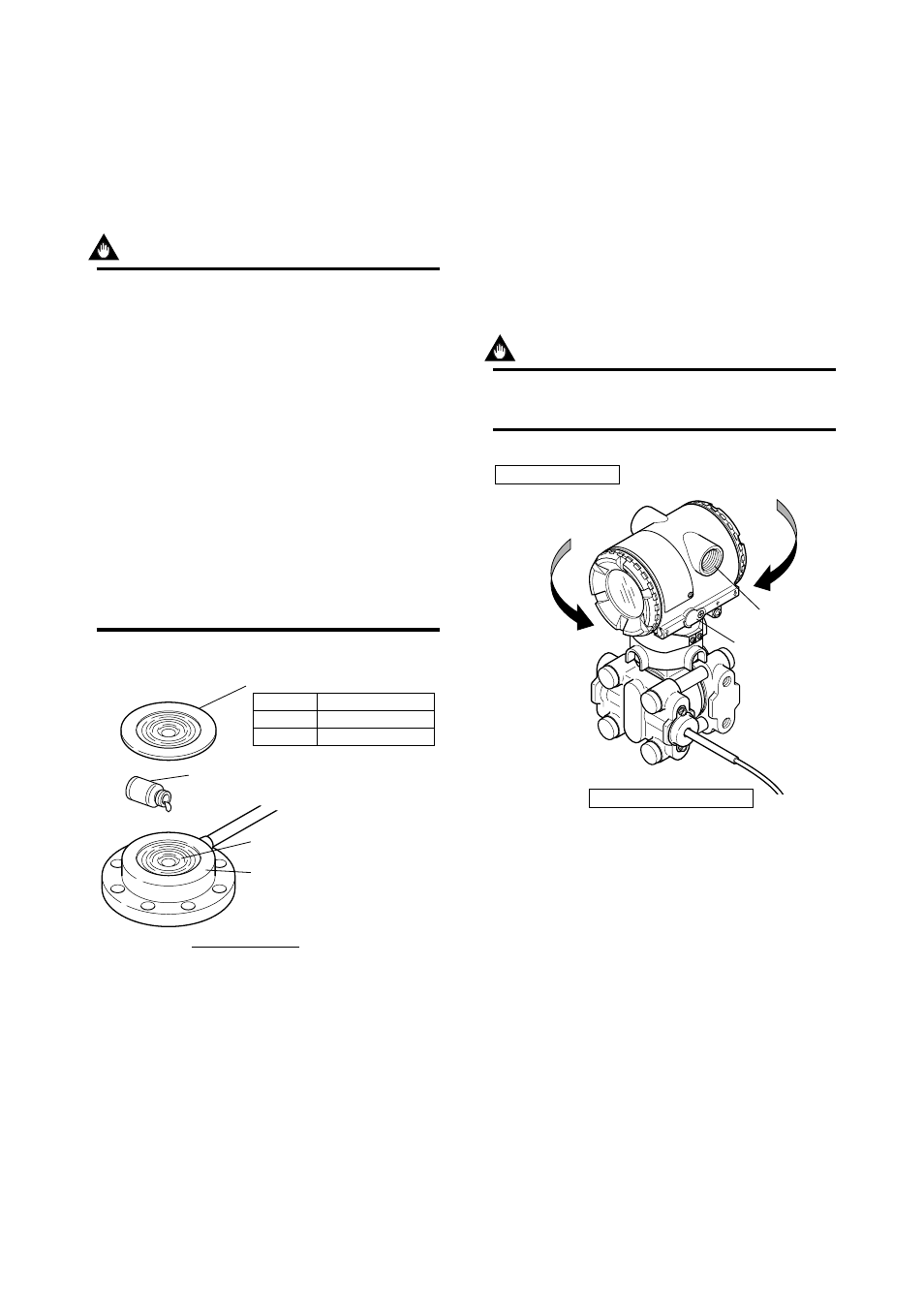

4.5 Rotating Transmitter Section

The DPharp transmitter section can be rotated in 90

°

segments.

(1) Remove the two Allen screws that fasten the

transmitter section and pressure-detector section,

using the Allen wrench supplied with the transmit-

ter.

(2) Rotate the transmitter section slowly in 90

°

segments.

(3) Tighten the two Allen screws.

IMPORTANT

Do not rotate the transmitter section more than

180

°

.

F0406.EPS

Rotate 90

°

or 180

°

segments

Rotate 90

°

or 180

°

segments

Transmitter section

Pressure-detector section

Conduit

connection

Zero-adjustment

screw

Figure 4.5.1 Rotating Transmitter Section