Application example, Declaration of conformity, Watlow tlm-8 user’s guide 5 – Watlow TLM-8 User Manual

Page 5: Example schematic, Series tlm-8

WATLOW TLM-8 User’s Guide

5

Application Example

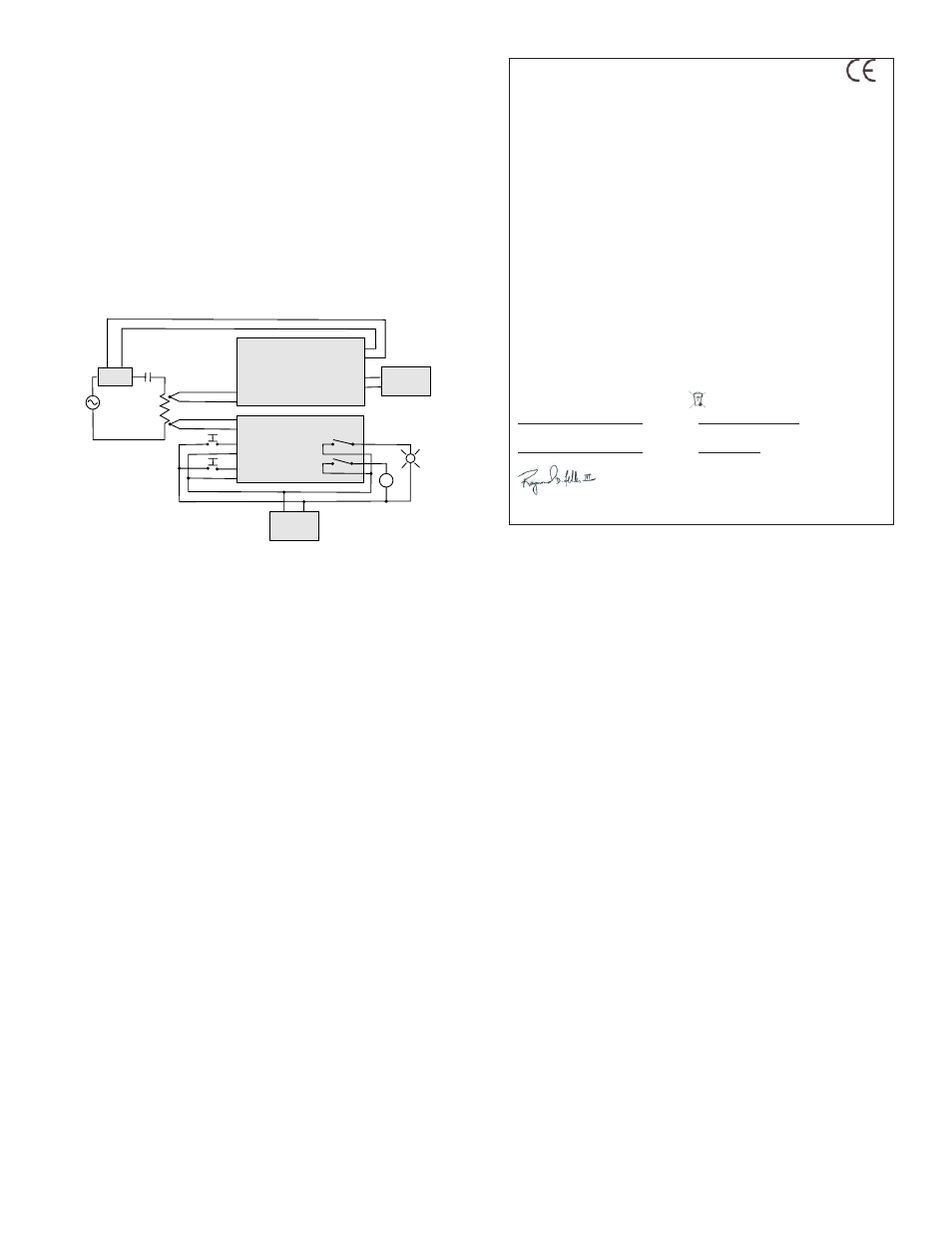

In the following example, a TLM-8 monitors tempera-

tures and provides independent safety shutdown, alarm

annunciation and acknowledgment. A multi-loop con-

troller, CLS200 or MLS300, is used for primary control.

The TLM-8 has its own set of thermocouples to monitor

temperatures independent of the controller. If a tem-

perature exceeds a trip point configured in the TLM-

8, then power to the heater is turned off by a TLM-8

controlled relay, and the System OK indicator light is

turned off. After the temperature drops and the cause

of the alarm has been corrected, an operator acknowl-

edges the alarm. The primary controller resumes con-

trol of the loop(s).

CLS/MLS Multi-Loop

Temperature Controller

TLM-8 Thermal

Limit Monitor

DC Power

Supply

DC Power

Supply

Solid-state

Relay

relay contacts

(normally open)

thermocouples

AC

heater

TST

ACK

relay

coil

System OK

indicator light

+

-

Example Schematic

NOTE: Relay contacts are illustrated in the unpowered or

alarmed state.

Declaration

of

Conformity

Series TLM-8

Watlow Winona, Inc.

1241 Bundy Blvd.

Winona, MN 55987 USA

Declares that the following product:

Designation:

Series TLM-8

Model Numbers:

TLM (C, E or P)(0 – 6)(0 or 1)(0 – 9)(additional letters or numbers indicating setpoint tempera-

tures.

Classification:

Temperature control, Installation Category II, Pollution degree 2

Rated Voltage and Power:

Control 12 to 24 V

Î (dc) 400 mA maximum

Note: Use of external CE approved ELV (UL Class 2) power supply required.*

Meets the essential requirements of the following European Union Directives by using the relevant standards show below to indicate

compliance.

2004/108/EC Electromagnetic Compatibility Directive

EN 61326

1997

A1:1998

A2:2002

A3:2004

Electrical equipment for measurement, control and laboratory use – EMC

requirements (Industrial Immunity, Class B Emissions).

EN 61000-4-2

1995

A2, 2001

Electrostatic Discharge Immunity

EN 61000-4-3

2002

Radiated Field Immunity

EN 61000-4-4

2004

Electrical Fast-Transient / Burst Immunity

EN 61000-4-5*

1995

A2, 2001

Surge Immunity

EN 61000-4-6

1996

A3, 2005

Conducted Immunity

EN 61000-4-11*

2004

Voltage Dips, Short Interruptions and Voltage Variations Immunity

EN 61000-3-2*

2001

ED.2.

Harmonic Current Emissions

EN 61000-3-3*

1995

A2:2002

Voltage Fluctuations and Flicker

73/23/EEC Low-Voltage Directive

EN 61010-1

2001

Safety Requirements of electrical equipment for measurement, control and laboratory use.

Part 1: General requirements

2002/96/EC WEEE Directive

Equipment Requires Recycling

Raymond D. Feller III

Winona, Minnesota, USA

Name of Authorized Representative

Place of Issue

General Manager

August 2007

Title of Authorized Representative

Date of Issue

Signature of Authorized Representative

Declaration of Conformity