Reelcraft Welding Reels Condensed Version User Manual

Operating instructions, Welding reels, Condensed version (welding)

Safety

1. Ensure that the reel is properly installed before

connecting input/output hoses or to power supply.

2. Bleed fluid/gas pressure from system and

disconnect all power before servicing the reel.

3. Before connecting reel to supply line, ensure that

pressure/voltage/amperage does not exceed maximum

working pressure/voltage/amperage rating of the reel.

4. Ensure that the reel, hose/cord and equipment being

serviced are properly grounded. Use an ohmmeter to

check ground continuity.

5. Pull hose/cord from reel by grasping the hose/cord

itself, not the work device.

6. A high tension spring assembly is contained

within the reel.

Exercise extreme caution.

7. If reel ceases to unwind or rewind, remove

system pressure/power immediately. Do not pull or jerk

excessively on hose/cord!

8. Treat and respect the reel as any other piece of

machinery, observing all common safety practices.

9. If a leak/electrical malfunction occurs in the hose or

reel, remove system pressure/power immediately.

10. Remember, even low pressure/low voltage is very

dangerous and can cause personal injury or death.

Exercise extreme caution.

12. Check for faulty supply wires or hoses before

operating.

13.

CAUTION: Do not shut off the fuel gas at the

regulator or supply source first, as a flashback may

result, and thereby damage the hose. Shut off the gas

at the torch first, and then at the regulator or supply

source, to limit permeation of gas through the hose wall.

This should be done when the torch will not be used for

periods in excess of 30 minutes.

14. After the flame has been extinguished and the gas

turned off at the supply source, it is recommended that

any remaining gas be bled to minimize degradation of

the rubber during long shutdowns.

15. To prevent an accumulation or concentration of gas

that could be explosive or otherwise harmful to person-

nel, adequate ventilation must be provided at all times,

particularly in confined areas where fuel gas is being

used.

Installation

For cable reels, ensure that only a qualified electrician

installs/services equipment. Observe applicable NEC,

OSHA, and local electrical codes when installing this

equipment. Unless reel was specified differently when

ordering, maximum installation height is 16 feet. Do not

exceed this distance.

Mounting & Guide Arm Adjustment

The reel is equipped for universal mounting so that it

can be mounted on a structurally sound floor, wall or

ceiling; whichever provides maximum performance. The

guide arm on spring driven reels must be rotated to a

position that allows the hose/cord to feed through the

roller brackets with minimal bending. Replace the

fasteners. Where applicable, the U-Bolt, which fastens

hose to spool, must be placed in the proper location

when rotating the guide arm, otherwise the reel might

“latch out” during use. Refer to online manual for proper

U-Bolt locations. Position reel to mounting surface and

secure into place, using four secure fasteners (not

included).

Install the Output Cord (Series WC)

1. Remove the three outer nuts on the collector ring

cover and remove the cover.

2. Strip 1 1/8” of insulation from the output cord and

insert cord around the reel spool (not through the guide

arm opening).

3. Add protective tubing around opening in spool.

4. (Series WC7000) Route the cord through the

opening in the spool, through the opening in the

collector ring base casting, then through the strain relief

until cord is between 2 clamp plates. Tighten clamp

plate fasteners until the cord is securely captured

between the plates; tighten strain relief. (Series

WC80000) Route cord through the opening in the spool,

through the strain relief, through the main shaft and then

capture cord at end of collector ring with set-screw.

Fasten strain relief to the main shaft and tighten cord

with strain relief.

5. Replace the collector ring with 3 outer nuts.

6. Fasten cord to spool by capturing with U-Bolt .

Fasten to spool with nuts/washers supplied.

7. Wrap all of the cord around the spool.

8. Once cord is on the spool, add additional turns to

add tension (2-3 should be sufficient).

9. Add cord bumper stop at desired location.

10. Use an ohmmeter, check for ground faults.

Install/Replace the Hose (Series TW)

CAUTION: Use extreme caution; reel under tension.

Avoid releasing the latch mechanism. Apply Teflon tape

to inlet/outlet connections. Refer to page 4 for inlet hose

connection instructional drawings.

1. Manually turn spool assembly until spring is tight,

back off three turns then latch.

2. Route output hoses through guide bracket.

3. Using a wrench, firmly hold onto output fittings

on swivel (Series 5000, 7000 & 8000) or fittings

on shaft (Series 30000 & 80000) while tightening the

hose connector.

Replace the Swivel

CAUTION: Remove supply line pressure before

performing the following procedure.

1. Remove supply line from swivel.

2. Remove swivel assembly from inlet shaft.

3. Apply thread sealant to threaded connection and

re-install swivel assembly to inlet shaft by reversing

steps 1 and 2.

Adjust the Reel

CAUTION: Use extreme caution; reel under tension.

Avoid releasing latch mechanism.

1. If necessary, adjust spring tension of reel by adding/

removing wraps of hose/cord from spool, one at a time,

until desired tension is obtained.

2. Add wraps to increase tension. Remove wraps to

decrease tension.

CAUTION: When adding wraps of

hose/cord, be careful not to exceed the winding

mechanisms spring capacity. Add just enough wraps of

hose/cord to achieve the desired tension. Damage to the

winding mechanism will result if spring is

over-tensioned.

Repairs

User servicing of the reel is limited to replacing the

hoses/cords or swivel only. Refer all other repairs

directly to the manufacturer. Failure to do so can result

in personal injury and/or equipment damage and may

void the warranty.

Operating Instructions

Condensed Version (Welding)

R

Reelcraft Industries, Inc.

2842 East Business Hwy 30, Columbia City, IN 46725 USA

Toll-free: 1-800-444-3134 or 260-248-8188

Toll-free fax: 1-800-444-4587 or 260-248-2605

www.reelcraft.com

Read these instructions carefully before attempting to install, operate or maintain this

product. Only qualified persons should install this product. Failure to comply with

nstructions may result in personal injury and/or property damage. Every attempt is made

to ensure the accuracy and completion of these instructions; however, manufacturer is not

responsible for ommissions. To obtain the complete version of Reelcraft’s service manu-

als, please visit www.reelcraft.com or call Customer Service during business hours. For

Technical Bulletins and support, please visit www.reelcraft.com.

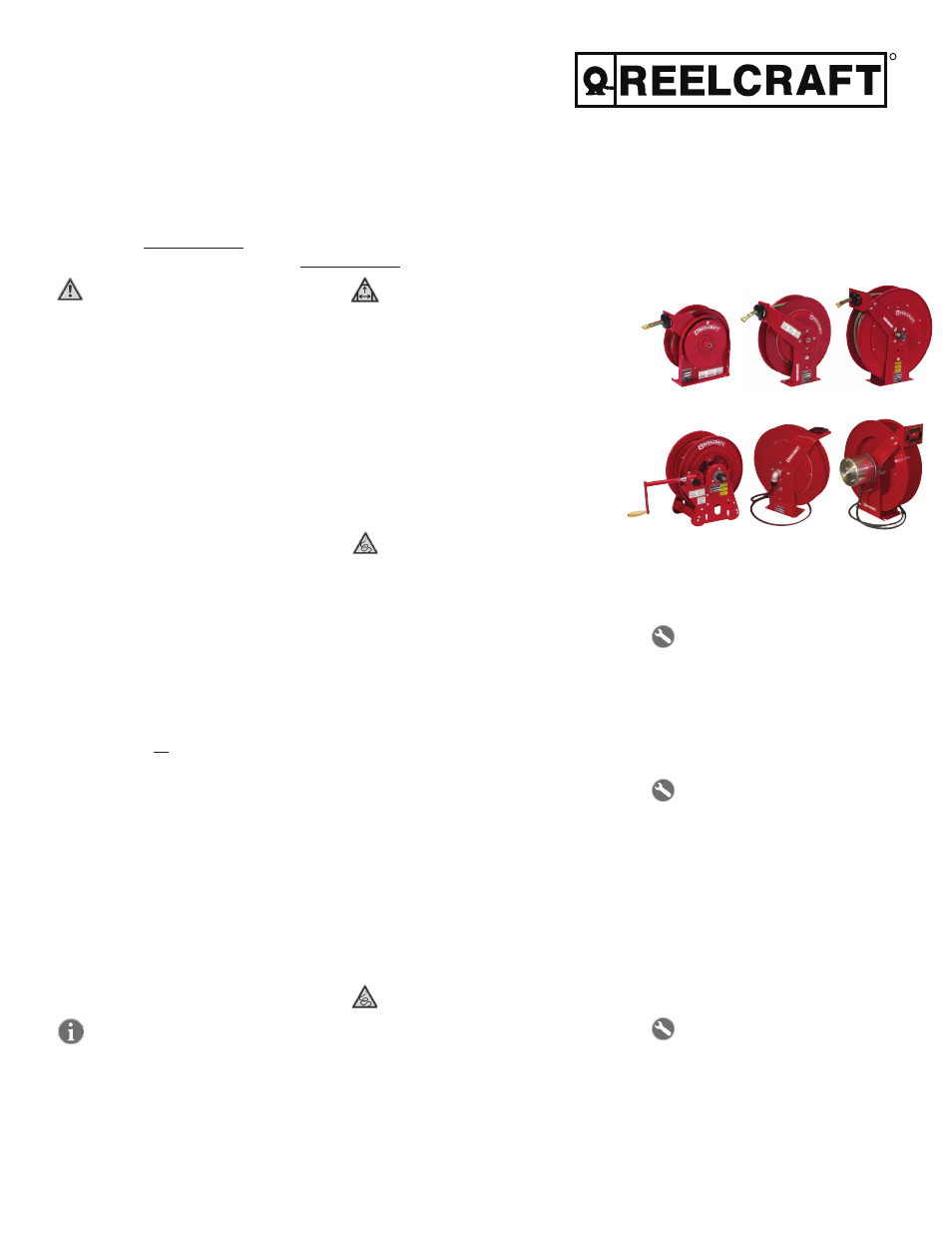

Welding Reels

Series TW Series WC Series BA

Refer to page 4 for dimensional drawings.

Series TW

TW5425 OLP

Rely on Reelcraft

TM

s

Better by Design

TM

Industrial s Automotive s Construction s Aviation s Fuel Delivery s Much more

www.reelcraft.com

Page 1

Series TW

TW7450 OLP

Series TW

TW84100 OLPT

Series BA

BA36106 L

Series WC

WC7000

Series WC

WC80001

Form #400-908 REVISED: 1/11