Hose reel operations manual – Reelcraft Nordic Series 4800 Reels User Manual

Page 2

•

Ensure that reel is properly installed before connecting supply line (see instructions).

•

Before connecting supply line to reel, ensure that supply line prssure does not exceed maximum rated working pressure of the

reel.

•

Do not wear loose fi tting clothing while operating reel.

•

Be aware of other personnel / machinery in work area.

•

If a leak occurs in hose or reel, remove supply line pressure immediately.

•

Treat and respect a hose reel as any other piece of machinery, observing all common safety practices.

PRE-INSPECTION

1. Check reel for shipping damages.

2. Insured all parts are supplied as ordered.

3. Record Model Number and Serial Number for future refer-

ence.

MOUNTING

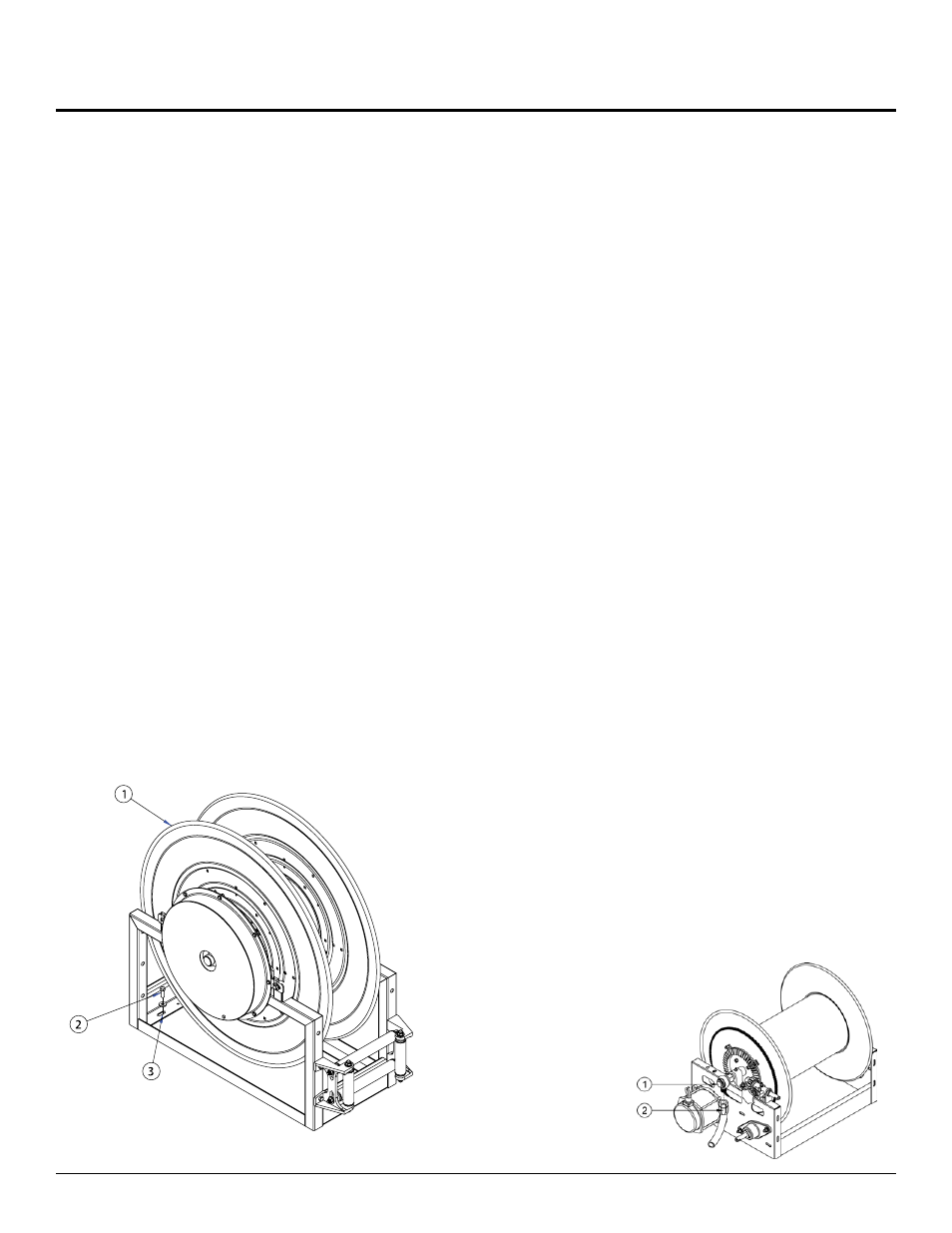

1. Unpack and inspect reel - rotating spool (1) to check for

smooth operation.

2. Ensure that mounting surface is rigid and flat to prevent

binding of reel after it is installed. This is important to en-

sure proper alignment.

3. Drill four mounting holes in reel frame. Secure reel to

mounting surface by inserting four bolts (2) through the

four mounting holes (3) just drilled into the reel frame.

Tighten securely to ensure a solid, rigid attachment.

Hose Reel Operations Manual

Page 2

www.reelcraft.com

PERSONAL SAFETY

•

Pull hose by grasping the hose itself not by the control valve swivel.

•

When working around flammable liquids such as solvents, paints, chemicals or petroleum products, ensure that the hose reel

and the equipment being serviced is properly grounded. Use a grounding hose (static wire).

•

Use an ohmmeter to check continuity of the grounding circuit. Fire and/or explosion can result if proper grounding is not

achieved.

•

If reel ceases to unwind or rewind properly, remove power immediately. Do not pull or jerk on hose. Find and remedy problem

before continuing.

WARNINGS & TIPS

Prevent static sparking

INSTALL / REPLACE THE HOSE

CAUTION: Exercise extreme caution when adding or remov-

ing spring tension. Ensure reel base is fastened down prior to

adjusting tension. Do not move spool while tightening hose or

latch will disengage. Do not let go of the hose until latch mech-

anism is engaged.

1. To achieve proper tension, wind spool flange required

number of turns (refer to online tech bulletin). Do not over-

tighten.

2. Engage hose latching mechanism.

3. Insert hose through roller guide.

4. Connect hose fitting to female outlet. Install hose bumper

stop at desired position.

INLET CONNECTION

NOTE: Install a union fitting as near as possible to the swivel

joint inlet, so the joint can be easily removed for servicing.

CONNECTING THE SUPPLY LINE FOR THREADED INLET

SWIVELS

NOTE: Avoid strain on swing joint at all swivel inlets must be

connected to the fluid supply by using a flexible connector.

1. Apply thread compound to the swivel (1) and connecting

hose fitting (2) threads.

2. Thread connecting hose fitting (2) into swivel (1). Tighten

securely.

3. With control valve open, fully extend and charge hose to

purge system of

gases. When fluid

appears at control

valve, close valve,

clos valve. This

prevents flattening

of hose and exces-

sive pressure on

drum when fluid

supply is reinitial-

ized at a later time.