Typical layout, Hydraulic schematic air system requirements, Clutch operation – Ramsey Winch RPH-50000 LARGE FLANGE 2-SPEED W/AIR TENSIONER User Manual

Page 6: Two speed control operation

3

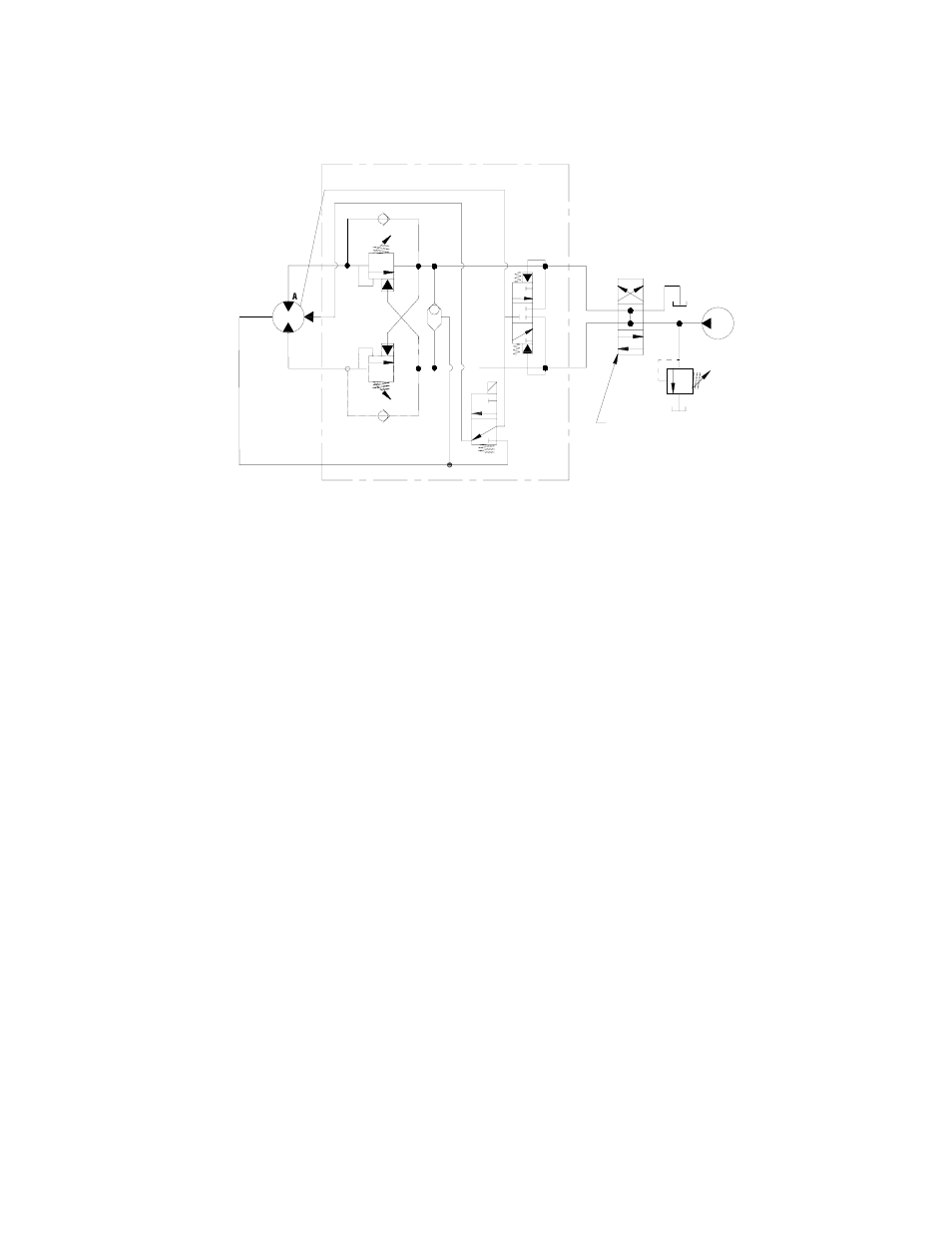

HYDRAULIC SCHEMATIC

AIR SYSTEM REQUIREMENTS

The cable tensioner requires an independent, adjustable regulated air supply of between 50 and 90 PSI.

CAUTION: DO NOT EXCEED 100 PSI AIR PRESSURE TO THE ACTUATORS. THIS COULD CAUSE DAMAGE TO THE

ACTUATORS.

The clutch release cylinder requires an air supply of between 100 and 120 PSI.

CLUTCH OPERATION

To engage clutch:

1. Move the clutch control valve to the “clutch engaged” position.

2. Anytime the temperature is below freezing, run the motor in the “cable out” direction only until the drum

starts to turn. In extreme cold temperatures (below 0º F/-18º C), pull out on the cable by hand only until the

drum starts to turn.

3. Wait at least 3 seconds for the clutch to fully engage, after which the winch is ready to winch in the cable.

WARNING: Do not attempt to engage the clutch by first running the winch motor and then moving the clutch

control valve to the "clutch-engaged" position while the motor is running. Do not start picking up the load at the

same time the clutch is being engaged.

To disengage clutch:

1. Run the winch in the "cable out" direction until the load is off the cable.

2. Move the clutch control valve to the "clutch-disengaged" position.

3. The cable may now be pulled off by hand.

TWO SPEED CONTROL OPERATION

Your winch is equipped with a 2-speed hydraulic motor. It is controlled by the application of 12 vDC to the

Motor Control Valve solenoid (12v applied to the solenoid provides high speed/low torque mode). Do not

change motor speed while the winch is in operation. Loss of load control and/or damage to your winch

could result.

TYPICAL LAYOUT

WITH BRAKE RELEASE SHUTTLE

DUAL (A & B) PORT MOTOR CONTROL VALVE

MOTOR

BRAKE

PORT

B

SYSTEM

RELIEF

3 POSITION

4 WAY VALVE

(MOTOR SPOOL)

PUMP