Ramsey Winch RPH-50000 LARGE FLANGE 2-SPEED W/AIR TENSIONER User Manual

Page 5

2

WINCH MOUNTING

Use (8) 3/4" diameter grade 5 or better bolts to attach winch to the wrecker.

Before operating the winch for the first time, remove the cover from the breather vent at the back of the air

cylinder and the relief fitting on top of the clutch housing.

CABLE INSTALLATION

1. Unwind cable by rolling it out along the ground to prevent kinking. Securely wrap end of wire rope, opposite

hook, with plastic or similar tape to prevent fraying.

2. Insert the end of cable, opposite hook end, into the hole in drum barrel. Secure cable to drum barrel, using

setscrew furnished with winch.

TIGHTEN SETSCREW SECURELY.

3. Carefully run the winch in the “reel-in” direction, winding one full wrap of cable on the drum.

4. Apply air to the cable tensioner. Wind about 5 wraps of cable onto the drum and stop. Using a hammer tap

these five wraps of cable over again the cable anchor flange side of the drum.

5. Finish spooling all the cable onto the cable drum, taking care to form neatly wrapped layers.

HYDRAULIC SYSTEM REQUIREMENTS

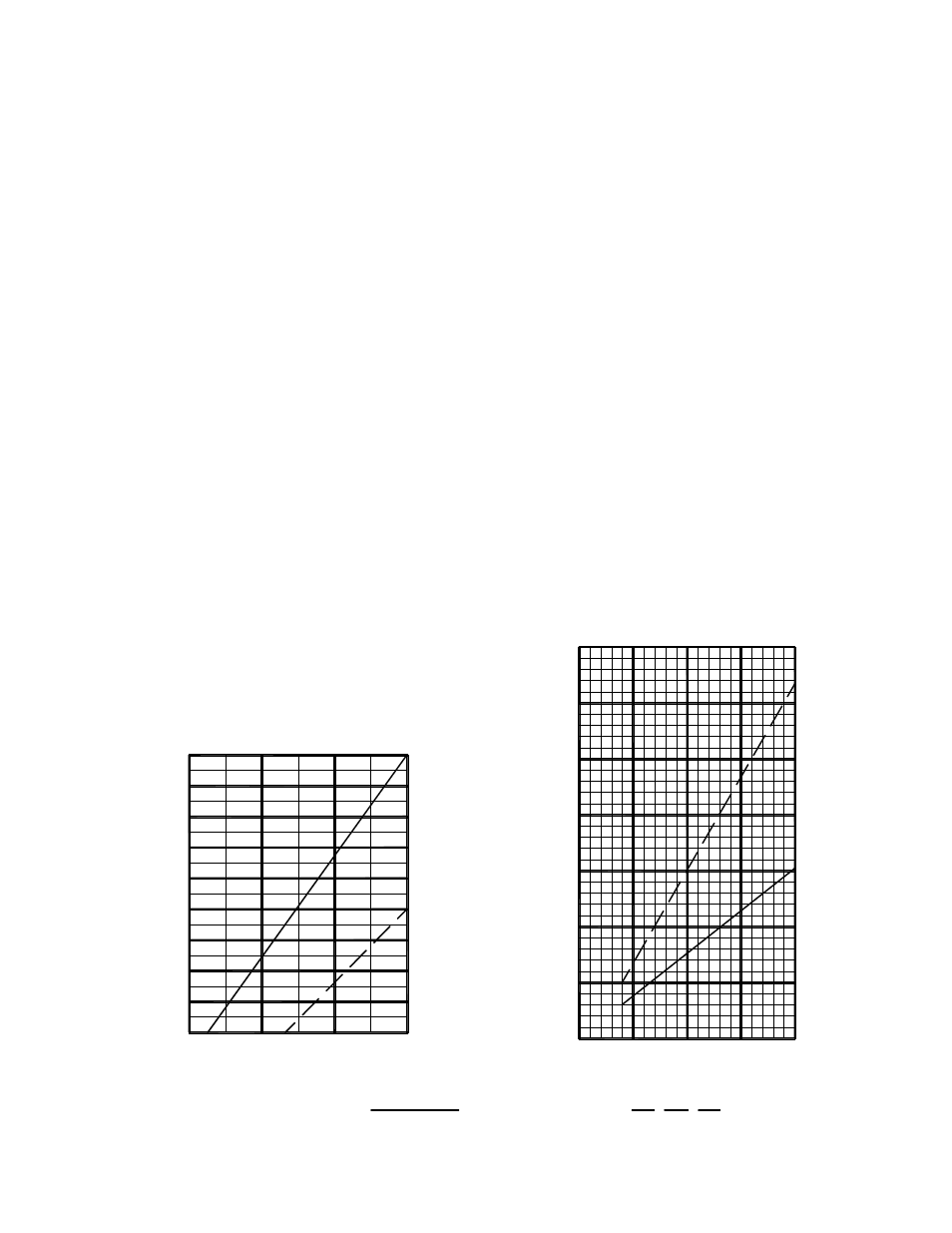

Refer to the performance charts to properly match your hydraulic system to RPH-50000 winch performance.

The charts consist of:

(1) Line pull (lb.) first layer vs. working pressure (PSI) and (2) Line speed (FPM), first layer vs. flow (GPM).

Performance based on a motor displacement of 11.9 cubic inches (at low speed) with 25 GPM maximum

flow rate. See page 16 for motor port size.

PERFORMANCE CHARTS

(BASED ON 11.9 CU. IN./REV MOTOR-LOW SPEED)

5,000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

0

1,000

2,000

3,000

WORKING PRESSURE (PSI)

LINE PULL (LB.), FI

R

ST

L

AYER

0

5

10

15

20

25

0

5

10

15

20

FLOW RATE (GPM)

LINE SPEED (FPM), FI

R

ST LAYER

35

30

LOW SPEED

HIGH SPEED

50,000