Cable tensioner overhaul – Ramsey Winch RPH-50000 LARGE FLANGE 2-SPEED W/AIR TENSIONER User Manual

Page 17

14

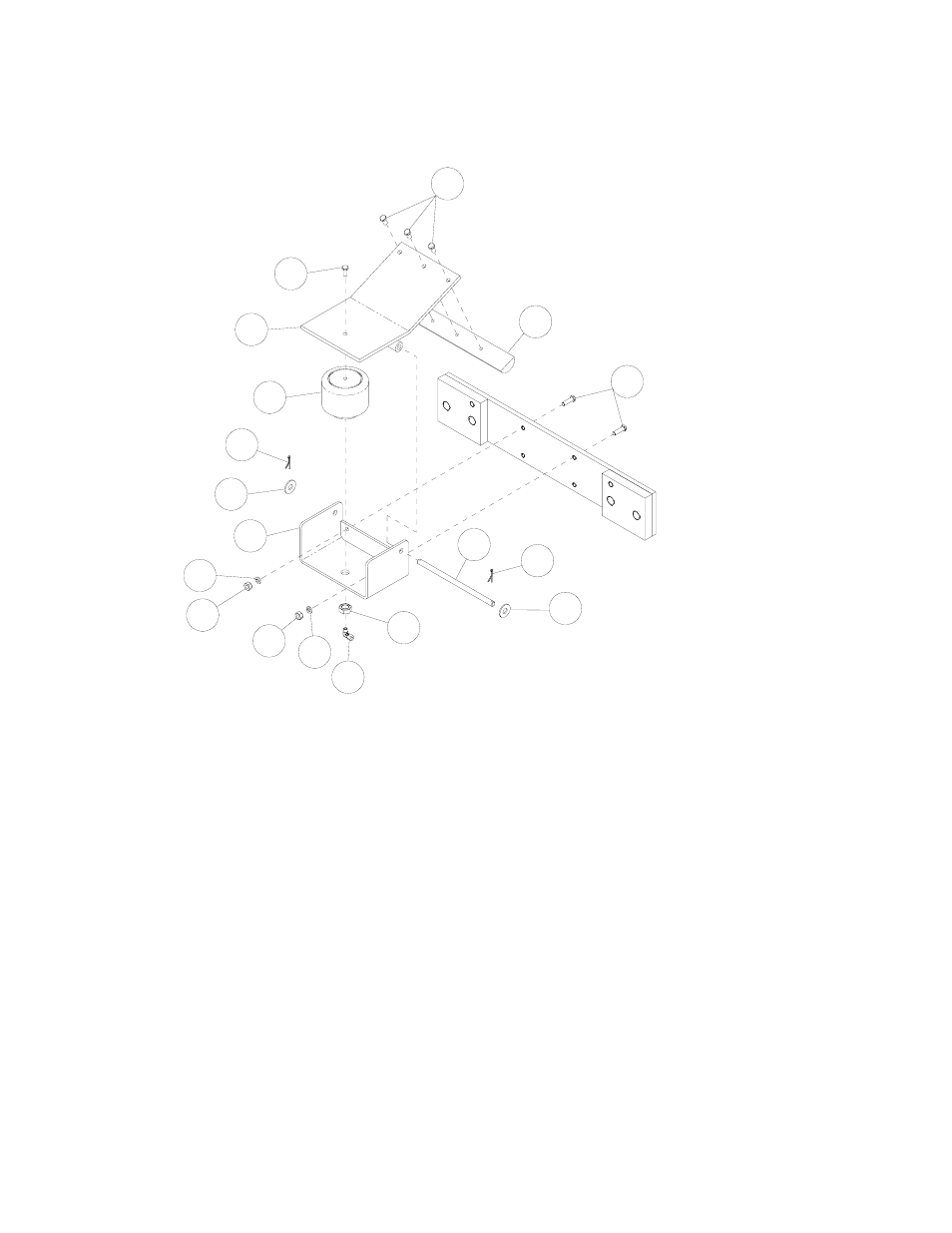

CABLE TENSIONER OVERHAUL

Note: Your winch will come in either an overwound or underwound version. The disassembly and

reassembly of the cable tensioner is the same for either, but the mounting of the cable tensioner to

the tiebar will be reversed for an underwound winch.

1.

Disconnect the air supply from the cable tensioner at the elbow fitting (item #12).

2.

Remove the tensioner from the tie bar by removing screws (item #6), nut (item #7) and washer

(item #9).

3.

Remove the screw (item #5) from the actuator (item #13) that holds the actuators to the

tensioner plate (item #1). Remove the nut (item #8) that holds that actuator to the bracket.

4.

Remove pin (item #3) by removing cotter pin (item #11) and washer (item #10) on both sides.

5.

Remove the tensioner plate and inspect the actuators for damage.

6.

Remove and replace any damaged parts. Tighten capscrews (item #5) that attach tensioner bar

to tensioner plate to 30 ft-lbs. torque.

7.

Insert the pin (item #3) through the bracket (item #4) and secure with the washer (item #10) and

cotter pin (item #11).

8.

Install the tensioner to the tie bar loosely. Center the tensioner bar between the drum flanges

with a scale or tape measure. Tighten the mounting bolts to 30 ft-lbs. torque.

3

1

2

11

10

9

7

7

8

4

10

11

6

5

5

13

9

12

TORQUE TENSIONER BAR MOUNTING BOLTS

TORQUE AIR BAG MOUNTING NUT

TORQUE AIR BAG MOUNTING BOLT

TORQUE TENSIONER BRACKET BOLTS

TORQUE AIR FITTING 90° ELBOW (INTO AIR BAG)

TO 8-10 FT. LBS.

TO 30 FT.LBS.

TO 15 FT. LBS. (MAX)

TO 20 FT. LBS. (MAX)

TO 30 FT.LBS.