Gear – Ramsey Winch RPH-25000 User Manual

Page 9

9

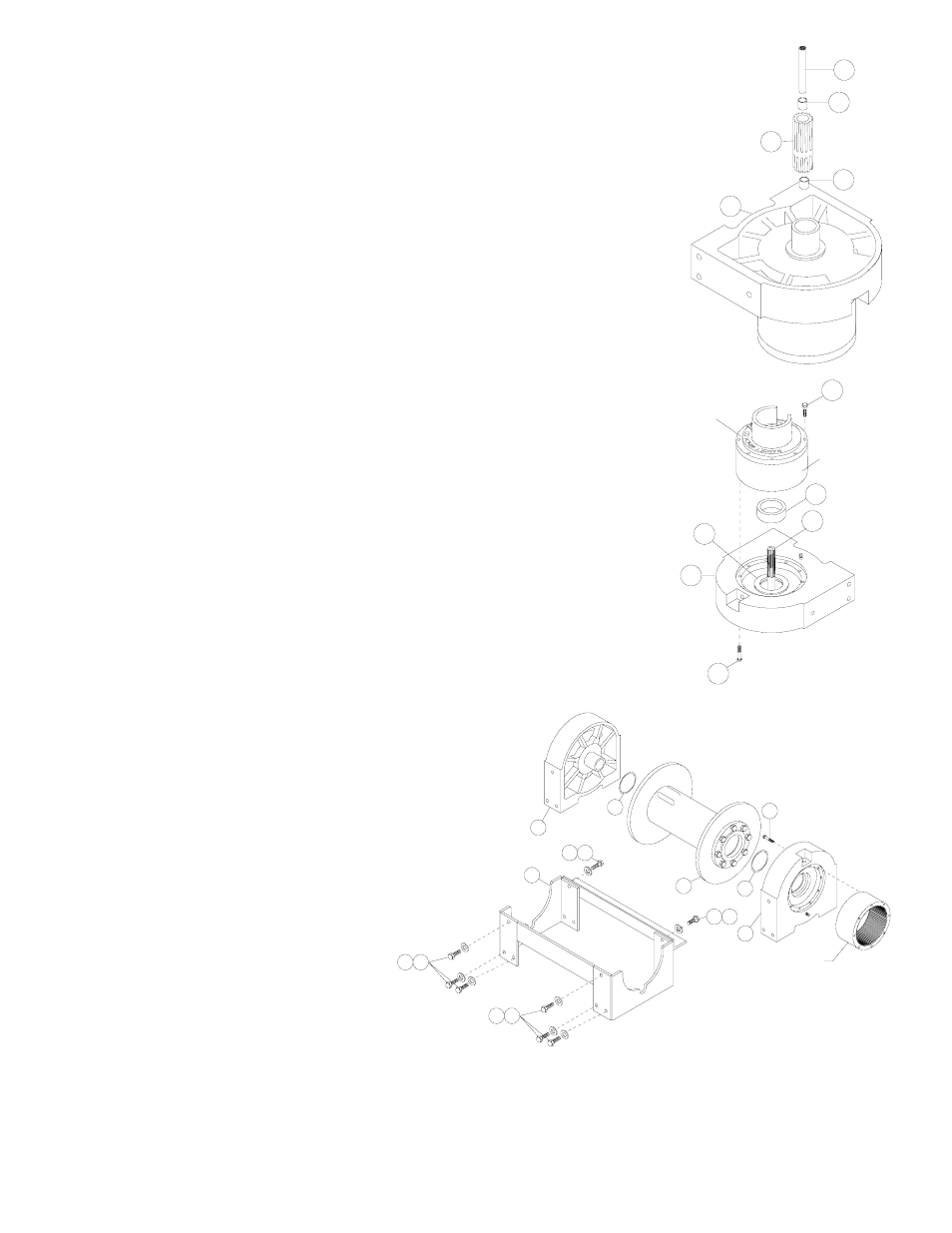

6. Remove output coupling (item #7) and coupling shaft (item #6) from end bearing (item

#9). Examine bearings (item #13), pressed in output coupling (item #7), for signs of

wear. Replace bearings, if necessary, by pressing old bearings from coupling and press

new bearings (item #13) into each end of output coupling (item #7). Place coupling

shaft (item #6) into bearings (item #13).

7. Remove (8) capscrews (item #15) to pull gear-housing cover from ring

gear

. Remove input thrust washer, sun gear, carrier assemblies, and

spacer (item #13) from inside of ring gear. Examine splines of ring gear

and if necessary, remove ring gear from end bearing (item #9) by

removing (12) capscrews (item #16). Examine bushing (item #14) for

signs of wear. Replace bushing, if necessary, by pressing old bushing

from housing and pressing new bushing into place.

Apply RTV sealing compound to ring gear-mounting surface of end bearing

(item #9). Place ring gear onto end bearing, aligning holes in ring gear with

holes and gear housing end bearing. Secure ring gear to end bearing using

(12) capscrews (item #16). Torque to 40 ft-lbs, each in a criss-cross pattern.

Examine shifter shaft (item #12) for signs of wear, replace if necessary.

8. NOTE: DETERMINE MOUNTING CONFIG-

URATION OF WINCH (R.H. or L.H.

MOUNTED) BEFORE ATTACHING FRONT

AND REAR FRAME ASSEMBLY TO WINCH,

TO ASSURE PARTS ARE MOUNTED TO

PROPER SIDE, REFER TO WINCH

MOUNTING CONFIGURATIONS, PAGE 6.

Seat well-oiled quad-rings (item #38 &

#39) into groove of bushing in each end of

drum assembly (item #2), as shown.

Carefully set drum assembly (item #2)

down over motor end bearing (item #9). Lift

gear-housing end bearing (item #9) and set

into place on drum assembly. Install frame

assembly (item #1) using capscrews and

lockwashers shown below. Tighten (4)

capscrews securely, check rotation of cable

drum.

9

6

7

14

14

GEAR HOUSING

COVER

9

15

12

RING GEAR

21

13

22

RING GEAR

25

16

16 25

1

8

39

17 25

17 25

2

9

40

22