Re-assembly – Ramsey Winch RPH 45000 OVERWOUND W/ AIR TENSIONER & 2 SPEED MOTOR User Manual

Page 11

9

RE-ASSEMBLY

8. NOTE: DETERMINE MOUNTING CONFIGURATION OF WINCH (R.H. or L.H. MOUNTED)

BEFORE ATTACHING UPRIGHT FRAME TO WINCH, TO ASSURE PARTS ARE MOUNTED

TO PROPER SIDE, REFER TO WINCH MOUNTING CONFIGURATIONS ON PAGE 12

.

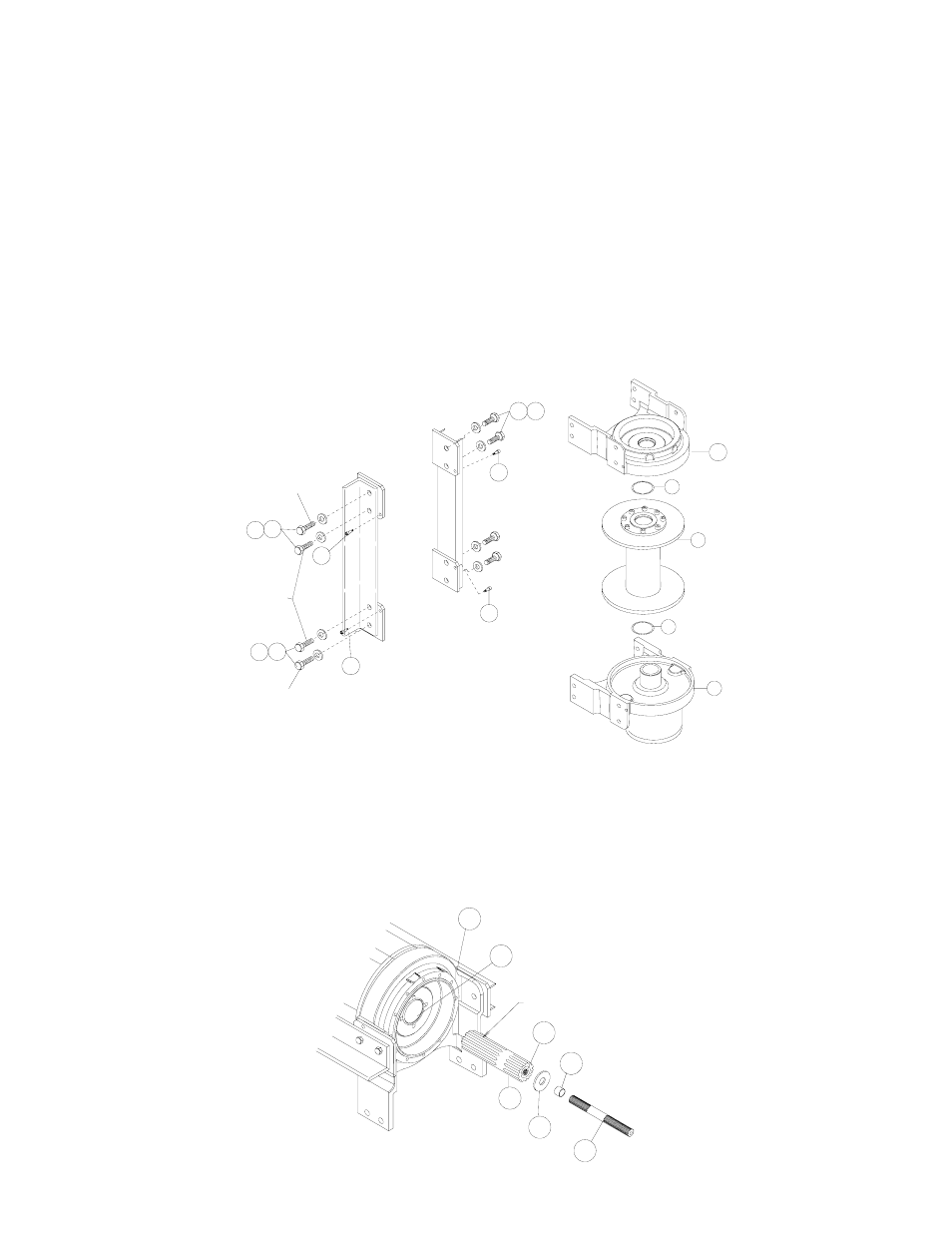

Seat well-oiled quad-ring #42 into groove of bushing in each end of drum assembly #1. Carefully

set drum assembly down over motor end bearing #9. Lift gear-housing end bearing #10 and set

into place on drum assembly. Attach tie bars #2 and #3 using (8) capscrews #19 and lockwashers

#24. Install (4) shoulder bolts #28 and hand tighten. Tighten (4) innermost capscrews securely;

check rotation of cable drum. Tighten (4) outer-most capscrews securely, check rotation of cable

drum. Torque capscrews, in above innermost then outer-most pattern, to 430 ft.-lbs. each. Torque

shoulder bolts to 30 ft.-lbs. each. Check rotation of cable drum assembly. It must rotate freely with

no tight spots.

9. Place end (with longest splines) of output coupling assembly #6 through end bearing bushing #15

and mesh coupling spline with spline inside of drum. Slide clutch spacer #30 over end and against

shoulder of shifter shaft #13. Place shifter shaft through washer #29 and into shaft coupling #7,

meshing splines of shifter shaft with splines in shaft coupling.

CAPSCREW

INNER-MOST

CAPSCREWS

OUTER-MOST

28

28

OUTER-MOST

CAPSCREW

28

28

10

1

9

19 24

19 24

19 24

42

42

LONGEST SPLINES

6

15

10

13

29

7

30